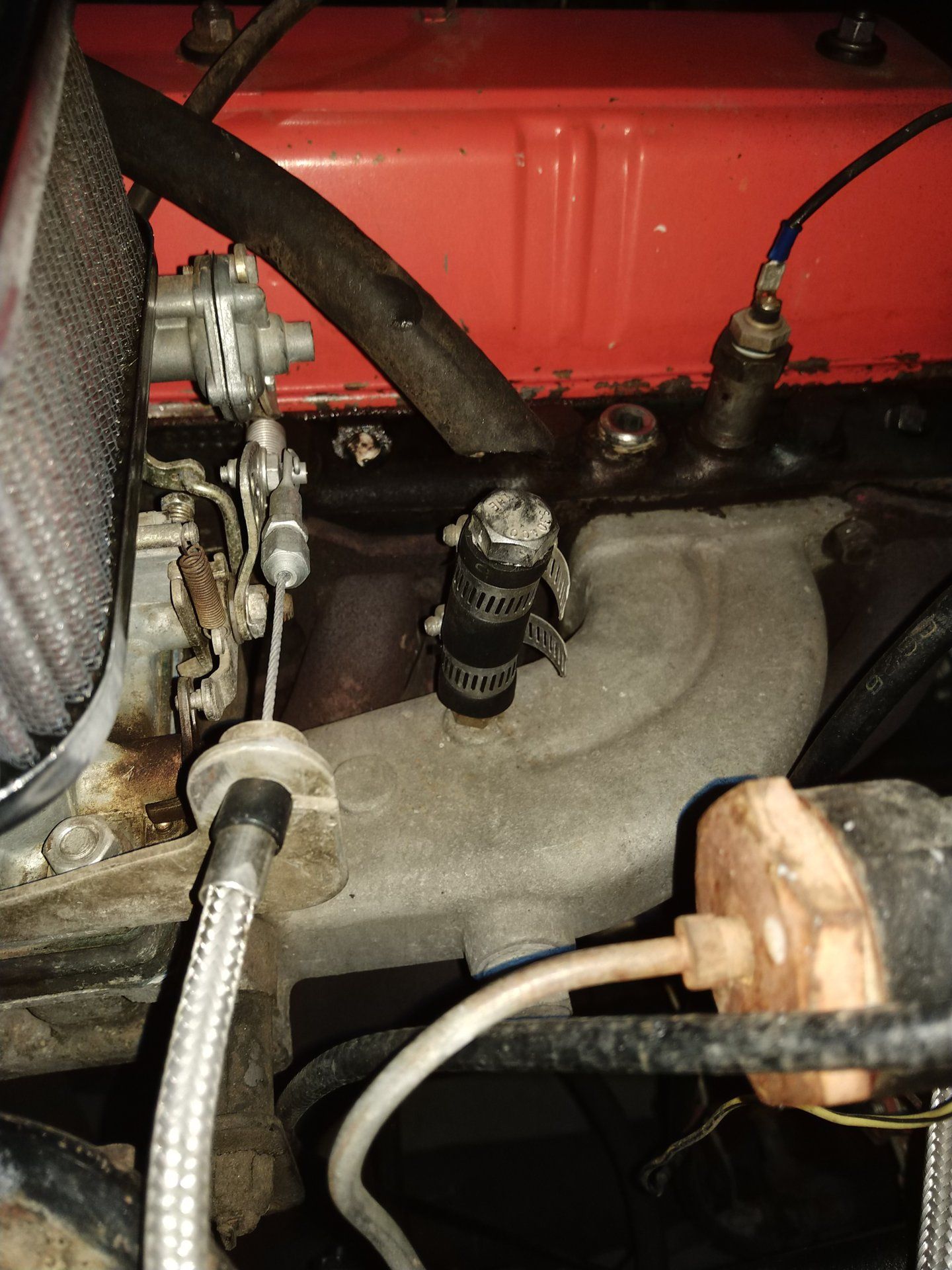

Hey Folks! So the PO stated that there was no PCV because the valve cover had no provision for one... Right. I THINK I found the hose for the PCV, but I do not see a bung for it anywhere. Was the PO correct? Do I need to tap a whole? Please forgive any ignorance I am showing in asking this question.

See pics:

Thanks!

See pics:

Thanks!