Awl_TEQ

Supporting Vendor

I purchased a cheap utility trailer to move parts of my 1978 FJ45 around during rebuilding it. Then we sold the wife's Sienna (that had a hitch). My Corolla has no hitch and no real capacity for towing so the wife's new Rav4 will get a hitch. The dealer sells them for around $1000.00 - way too much $$ for a hitch. I have access to tools and material required and figure I can make one from scratch for something like $50.00. That will cover the receiver sleeve, bolts and a plug and play wiring harness (The one for the Sienna was $30.00). I get scrap material from work for free (as long as it isn't too much at any one time  )

)

Mudder member John E Davis put a factory hitch on his Rav4 and did a very good write up on the process on his family website with very good pictures. His write up shows the necessity of many contact points to spread the load around the unibody frame of the Rav. With the power of the late model Rav, 269Hp I think, one could twist and deform the structure pretty quickly. I will copy the general layout of the factory frame mostly because we all know Toyota makes good stuff.

Here is a poor shot of our 2008 Rav4, only two months old, at my place of employment. YES, I Do wash it. It had snowed quite a bit previously.

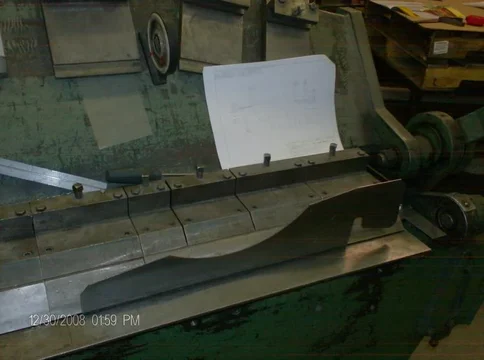

This is a photo of the left (drivers side) "frame rail". It looks to be a doubled 14 Ga. hat channel incorporated into the unibody. Notice the tie down for shipping and the bolts for that tie down. The rail has M12 x 1.25 metric captured nuts in four places. These will be the main anchor points for the bolt on hitch assembly I will make.

Here is the right (pass. side) frame rail. There is the added complication of the muffler/ tailpipe assembly on this side. Also there are only three nuts in the rail here.

Mudder member John E Davis put a factory hitch on his Rav4 and did a very good write up on the process on his family website with very good pictures. His write up shows the necessity of many contact points to spread the load around the unibody frame of the Rav. With the power of the late model Rav, 269Hp I think, one could twist and deform the structure pretty quickly. I will copy the general layout of the factory frame mostly because we all know Toyota makes good stuff.

Here is a poor shot of our 2008 Rav4, only two months old, at my place of employment. YES, I Do wash it. It had snowed quite a bit previously.

This is a photo of the left (drivers side) "frame rail". It looks to be a doubled 14 Ga. hat channel incorporated into the unibody. Notice the tie down for shipping and the bolts for that tie down. The rail has M12 x 1.25 metric captured nuts in four places. These will be the main anchor points for the bolt on hitch assembly I will make.

Here is the right (pass. side) frame rail. There is the added complication of the muffler/ tailpipe assembly on this side. Also there are only three nuts in the rail here.