Well, I got a surprise while doing a routine rear axle service on a FZJ80. Out of curiosity while the axle shafts were out I ran one of those telescoping pick-up magnets into the axle housing via the spindles not expecting to find anything. The right/short side had essentially no debris but the long side (where the breather vent is located) had quite a few flakes/particles of rust.

The differential drain plug magnet also had more than the usual amount of magnetic dust or "beard" along with some small flakes of rust that crumbled easily (see photos). Ran a couple different magnetic wands in and out a couple dozen times and followed that by flushing the axle tubes with a couple quarts each of kerosene and saw that more rusty flakes/debris were washed out into the collection pan.

Since I've owned this 80 it was never driven into deep water however I did find that the rear axle breather valve was stuck open so every time the axle housing cooled off after a drive it likely sucked in the humid air of this region.

So planning to send out a sample of the used gear oil to Blackstone Laboratories for analysis but it does not look milky and doesn't layer out after sitting overnight. I'll do some more flushing, might run 2" cylindrical brush into the axle housing via the spindles to knock off any remaining loose flakes, flush again, etc,etc.

Some people might want to pull the diff carrier or even drop the axle housing all together and pressure wash the inside of the axle, maybe treat the inner surfaces with a phosphoric acid product (with diff removed) to kill/stop any rust. But I'm thinking between the flushing, brushing and some extra magnets to grab any loose rust particles along with a new functioning breather I might get away with watchful waiting for now.

The main point of all this is to remind people to check your axle breathers, particularly the rear which is harder to get to than the front so easier to ignore. It can be accessed by removing the left rear wheel (after jacking up the vehicle, installing jack stands---) and reaching/leaning in on the front side of the axle. FWIW

Photos tell the story:

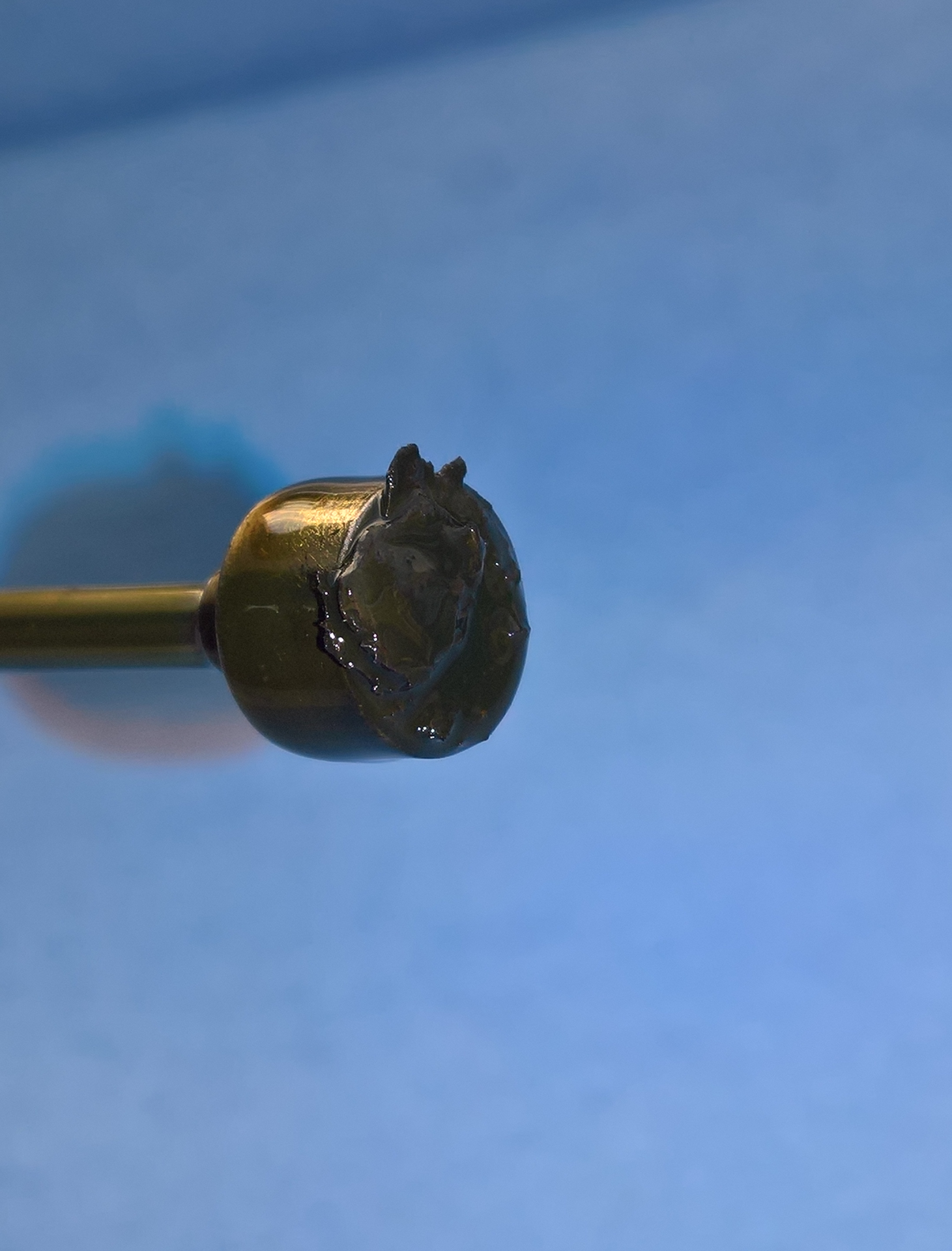

This is what came out with the first few passes with the magnet. Probably got that amount on the magnet 4-5 times from multiple passes in and out.

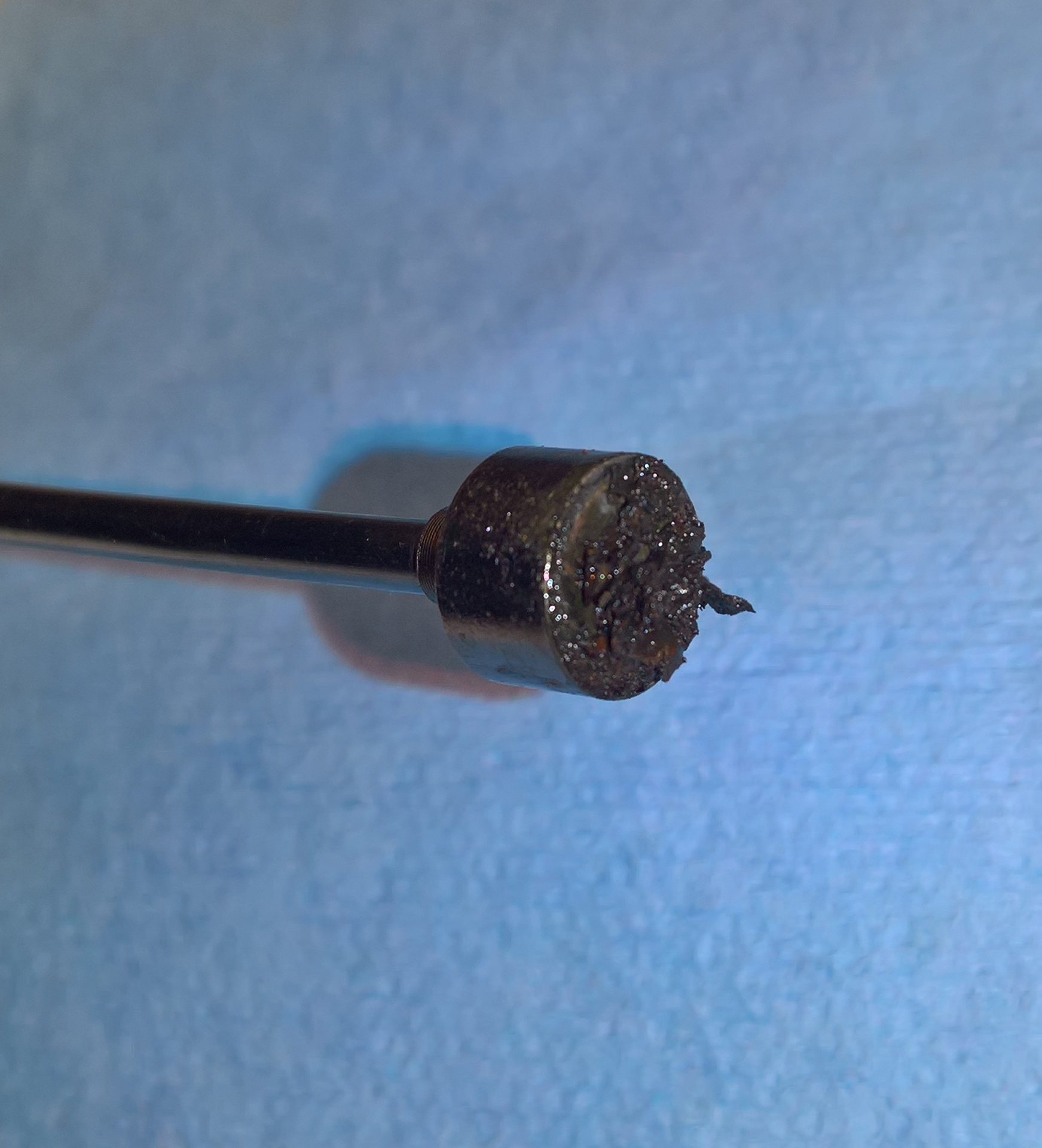

This shows the larger magnetic pick-up tool with a stronger neodymium magnet added for more power but most of the junk had already been cleaned out by the smaller magnet (what could be picked up with a magnet at least) before I tried this one.

This is the drain plug which was partially/gently washed off with solvent to better show the debris before it was touched, most of which turned to mush when wiped off. The black color is due to a Moly gear oil additive.

Cllick photo twice to magnify

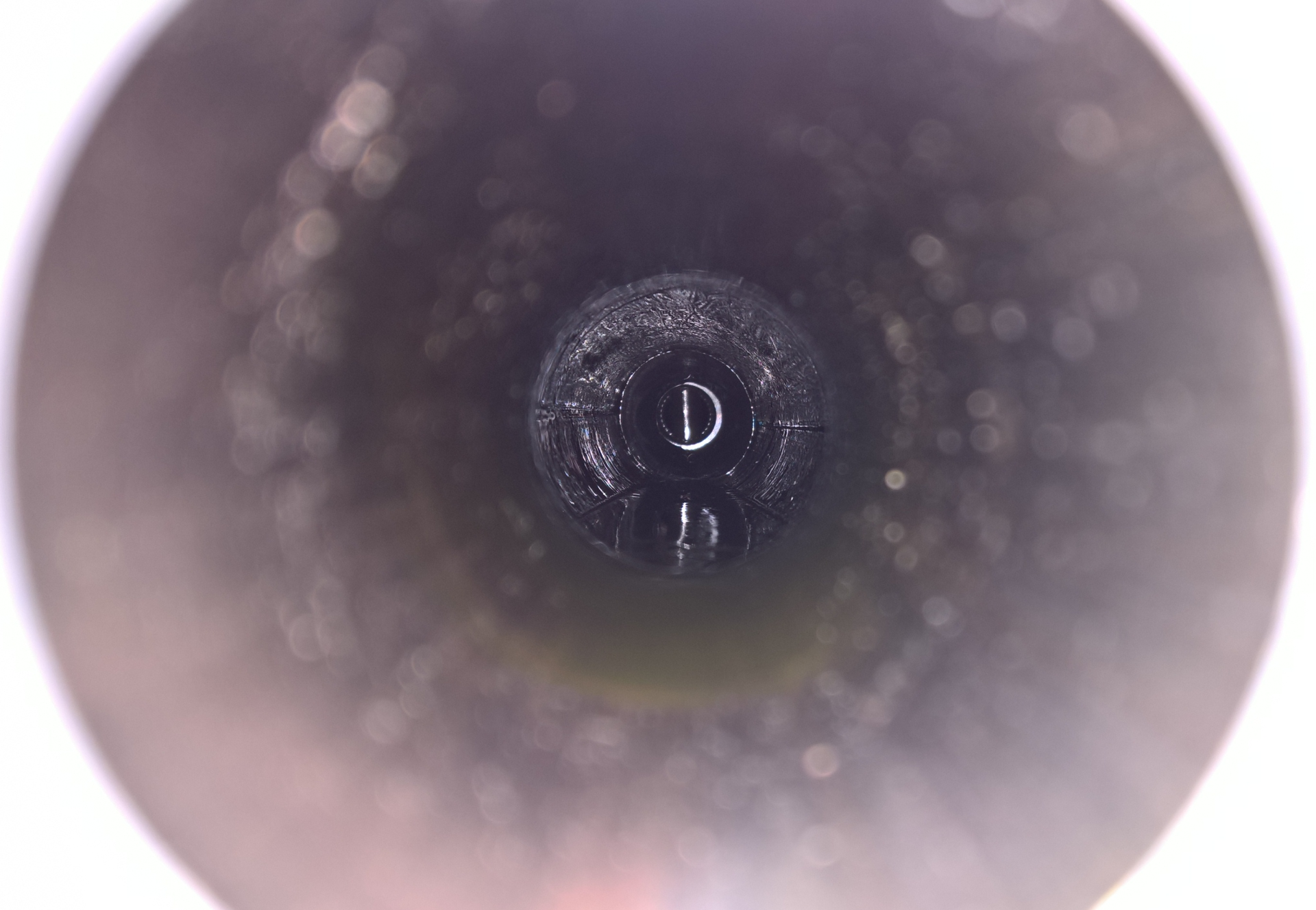

This is looking in through the left side spindle tube. Click twice to magnify for more detail. You can barely make out what looks like dark ?rusty patches on the upper aspect/roof of the housing.

The differential drain plug magnet also had more than the usual amount of magnetic dust or "beard" along with some small flakes of rust that crumbled easily (see photos). Ran a couple different magnetic wands in and out a couple dozen times and followed that by flushing the axle tubes with a couple quarts each of kerosene and saw that more rusty flakes/debris were washed out into the collection pan.

Since I've owned this 80 it was never driven into deep water however I did find that the rear axle breather valve was stuck open so every time the axle housing cooled off after a drive it likely sucked in the humid air of this region.

So planning to send out a sample of the used gear oil to Blackstone Laboratories for analysis but it does not look milky and doesn't layer out after sitting overnight. I'll do some more flushing, might run 2" cylindrical brush into the axle housing via the spindles to knock off any remaining loose flakes, flush again, etc,etc.

Some people might want to pull the diff carrier or even drop the axle housing all together and pressure wash the inside of the axle, maybe treat the inner surfaces with a phosphoric acid product (with diff removed) to kill/stop any rust. But I'm thinking between the flushing, brushing and some extra magnets to grab any loose rust particles along with a new functioning breather I might get away with watchful waiting for now.

The main point of all this is to remind people to check your axle breathers, particularly the rear which is harder to get to than the front so easier to ignore. It can be accessed by removing the left rear wheel (after jacking up the vehicle, installing jack stands---) and reaching/leaning in on the front side of the axle. FWIW

Photos tell the story:

This is what came out with the first few passes with the magnet. Probably got that amount on the magnet 4-5 times from multiple passes in and out.

This shows the larger magnetic pick-up tool with a stronger neodymium magnet added for more power but most of the junk had already been cleaned out by the smaller magnet (what could be picked up with a magnet at least) before I tried this one.

This is the drain plug which was partially/gently washed off with solvent to better show the debris before it was touched, most of which turned to mush when wiped off. The black color is due to a Moly gear oil additive.

Cllick photo twice to magnify

This is looking in through the left side spindle tube. Click twice to magnify for more detail. You can barely make out what looks like dark ?rusty patches on the upper aspect/roof of the housing.

Last edited: