vszUnclear

Glutton for Punishment

I know there are a bunch of "hesitation/stumbling" threads and i've read everything I could on this topic but I'm still not finding the source of my problem.

87 FJ60 with about 148K.

From a dead stop as I accelerate in 1st gear there is a stumble or RPM drop between about 1000-1500 rpms depending on the situation. I can literally see my tach drop a few hundred rpms as I'm accelerating giving gas. Most noticeable under load (hills). Seems most profound when cold, but it does happen at all temps.

I don't get any hesitations in gears 2-4 or at higher rpms in 1st. It's just that one little hicup, but it's critical because I live in a hilly area.

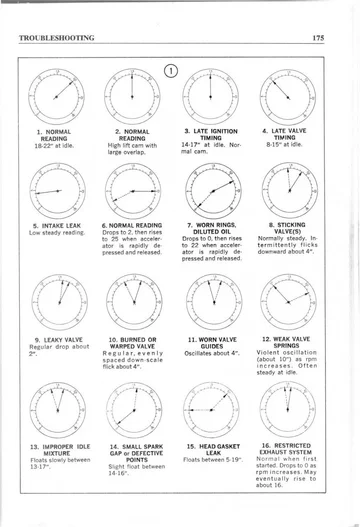

This problem has existed since I bought the rig in 2012. I've fully desmogged (has cat, no HAC). I've done a number of things trying to find the sources of my issue: new vac lines, new manifold gasket, carb lean drop, new fuel pump, fuel filter, tried unplugging the tach, tried unplugging emissions box, compression is pretty good (140s), new spark plugs/cables, new recurved/rebuilt dissy, timing adjustments (on BB, 7 deg BTDC), intake vac pressure is 16.5, exhaust is about 17, sprayed carb cleaner looking for intake leaks.

I have not yet rebuilt the carb but it's on the list. Pretty sure my secondary diaphragm doesn't work but that doesn't seem like it would affect this.

Anyone with similar experiences or possible culprits to chase down?

Thank you all.

87 FJ60 with about 148K.

From a dead stop as I accelerate in 1st gear there is a stumble or RPM drop between about 1000-1500 rpms depending on the situation. I can literally see my tach drop a few hundred rpms as I'm accelerating giving gas. Most noticeable under load (hills). Seems most profound when cold, but it does happen at all temps.

I don't get any hesitations in gears 2-4 or at higher rpms in 1st. It's just that one little hicup, but it's critical because I live in a hilly area.

This problem has existed since I bought the rig in 2012. I've fully desmogged (has cat, no HAC). I've done a number of things trying to find the sources of my issue: new vac lines, new manifold gasket, carb lean drop, new fuel pump, fuel filter, tried unplugging the tach, tried unplugging emissions box, compression is pretty good (140s), new spark plugs/cables, new recurved/rebuilt dissy, timing adjustments (on BB, 7 deg BTDC), intake vac pressure is 16.5, exhaust is about 17, sprayed carb cleaner looking for intake leaks.

I have not yet rebuilt the carb but it's on the list. Pretty sure my secondary diaphragm doesn't work but that doesn't seem like it would affect this.

Anyone with similar experiences or possible culprits to chase down?

Thank you all.