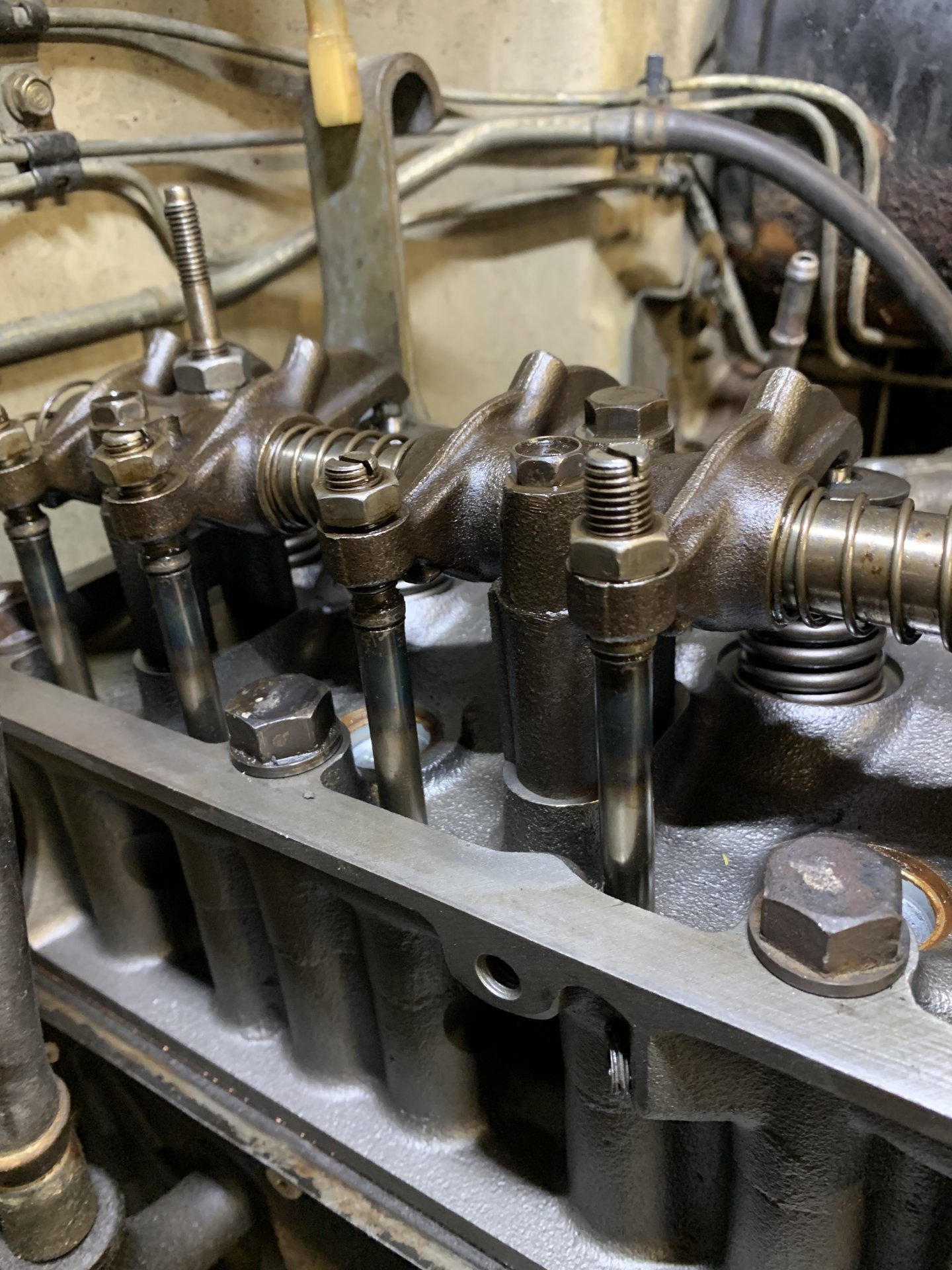

Following the guide here: How to adjust your 2f valve clearance - https://forum.ih8mud.com/threads/how-to-adjust-your-2f-valve-clearance.1152737/

1979 FJ40. My distributor is I think not stock. It is points only and the igniter has been removed. Cap is made in USA and has no provisions for vents. Older Toyota?

When I have the timing marks lined up (at least I believe so), the rotor points to the #5 plug hole not between 3 and 4 as the guide and Haynes says.

If I try to adjust #7 or #9 at this point, I have a lot of threads left on the screw, it is backed almost all the way out. All other valves marked “a” in the chart adjusted normally, as did other “b”s.

This just looks odd to me, what’s up? Or is this normal? Distributor rotor position, can that vary? Screws backed so far out?

Any advice appreciated.

EDIT: I should add, this truck ran well before I pulled the head to do the gasket and I have not touched the distributor.

1979 FJ40. My distributor is I think not stock. It is points only and the igniter has been removed. Cap is made in USA and has no provisions for vents. Older Toyota?

When I have the timing marks lined up (at least I believe so), the rotor points to the #5 plug hole not between 3 and 4 as the guide and Haynes says.

If I try to adjust #7 or #9 at this point, I have a lot of threads left on the screw, it is backed almost all the way out. All other valves marked “a” in the chart adjusted normally, as did other “b”s.

This just looks odd to me, what’s up? Or is this normal? Distributor rotor position, can that vary? Screws backed so far out?

Any advice appreciated.

EDIT: I should add, this truck ran well before I pulled the head to do the gasket and I have not touched the distributor.