Ok, it seems I messed up with my assumptions. It looks like the clutch housing from the HJ75 is different to that off the HJ47. I measured up, looked from different angles, compared the two, and I'm pretty certain that the clutch housing that I have installed with the H55F has a different flange orientation relative to each end than that from the H41. What I mean is that the clutch housing from the HJ75 sets the angle of the transmission differently than that of an Hj47. It looks like the HJ75 clutch housing tilts the transmission slightly to the right by a few degrees, hence dropping the companion flange side of the transfer case closer to the floor... Or so it seems.

The only other thing that I can think of is if the four-hole pattern on the front of the transmission that joins it to the clutch housing is in a slightly different orientation, though I doubt it as I did a bit of research before doing this swap, and hadn't heard anything of this issue before, though every one that I read about had used the existing (H41) bellhousing.

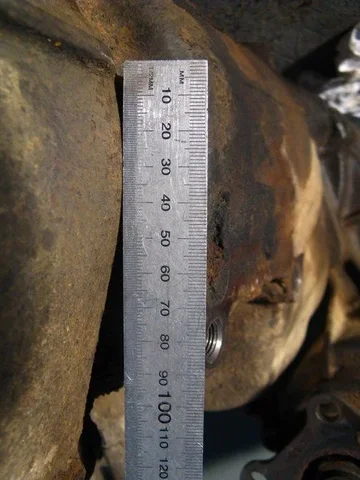

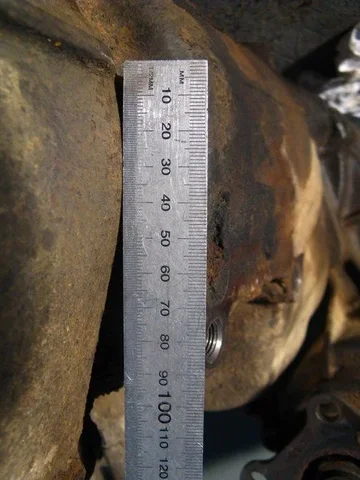

I measured the offset from the bottom rib of the clutch housing to the right hand front bolt that secures the tranny to the cradle.

H41 - roughly 80mm:

H55F - roughly 65mm:

Obviously, the bolt spacing on the bottom of the transmission is the same on both, but relative to the bottom of the bellhousing, the offset is 15mm different.

A quick snap of the offset - note the angle of the rib on the bottom of the clutch housing relative to the bottom of the transmission:

The only thing that I was unsure of before I started this install was

if the clutch housing from the 75 would work. Now its come back to bite me on the ass

I could drive it around as is, on the tarmac - no worries, on the trail - I wouldn't want to risk it. I want to do this thing right. So it looks like I'll be pulling the transmission off again, changing out the clutch housings and reinstalling it.

Unless anyone has any other suggestions ..............

please!

Not to mention the fact that you would have to do all sorts of fabricating to your transmission cradle to get the non-slip yoked end to fit without rubbing.

Not to mention the fact that you would have to do all sorts of fabricating to your transmission cradle to get the non-slip yoked end to fit without rubbing.