reddog90

SILVER Star

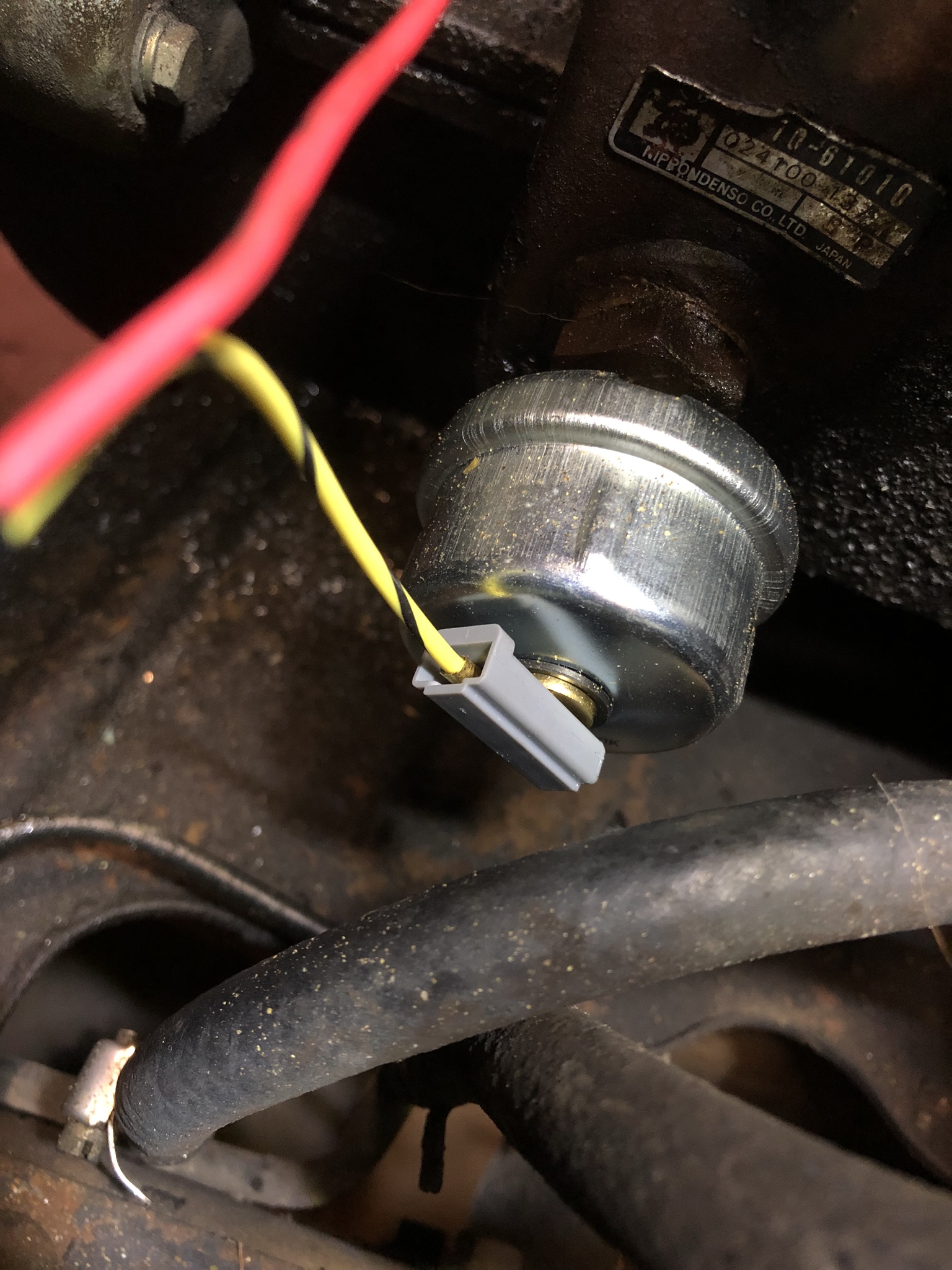

I apologize for the novel. I’m having trouble diagnosing some problems with my new oil pressure sender unit and I want to list out everything I have tried so far. Here’s how it looked when I got the truck:

I had my wife watch the oil pressure gauge while I touched the stripped wire to the broken connector on the old sender, gauge in the dash worked and the needle was at about half while the truck was idling. So I ordered a new OEM sender unit from CC and got some 14-16 ga spade connectors.

I put on a female spade connector, put some Teflon tape on the sender unit's threads and installed it. Started the truck and gauge in the dash read 0. I decided to test the sender. I grounded a test light on the battery, touched the light to the brass connector on the new sender looking for a dim light at idle and got nothing.

I did some more research on mud and found old threads with people saying to not use Teflon tape since OEM senders ground through their threads to the engine. But the FSM does say to use “sealant” on the threads and the old sender definitely had some sort of old sealant on it. So I took the new sender out, cleaned the threads, reinstalled and still the gauge read 0.

Then I tried to rule out a grounding issue somewhere else. I connected a test light from the battery to the spade connector I had installed and the gauge went full tilt over H.

Now I’m confused. My neighbor helping me delicately slips my new spade connector onto the new sender unit while the truck is idling and the gauge works properly. I think “WTF?” and reach in to grab the spade connector to feel how he put it on the sender, and then the signal to the dash went out and gauge dropped back to 0.

So now I assume it’s a problem with the spade connector I put on. So I removed the spade connector, start the truck, touch the stripped wire to the connector on the new sender unit and gauge in the dash reads 0.

With the new sending unit still installed and wires not connected, I connected a test light from the battery and tested for a ground on the housing of the sending unit and the brass threads and got a bright light. This makes me think the sending unit is grounding properly.

I try to go back to step 1 by reinstalling the old sending unit and touching the stripped wire to the broken connector, but the gauge now reads 0. I test for a ground and it is grounding properly. So now I’m worried I burned out the gauge in my dash. So I connect the test light to the battery and touch the stripped wire, and the gauge moved. So my gauge shouldn’t be burned out.

I am very confused what to try next. It seems like my gauge in my dash is working, my wiring is good, and the new sender is grounding properly. And I have removed the possibility of a bad spade connector from the equation. Is it possibly my sender unit is bad? Any ideas on what to try next?

I had my wife watch the oil pressure gauge while I touched the stripped wire to the broken connector on the old sender, gauge in the dash worked and the needle was at about half while the truck was idling. So I ordered a new OEM sender unit from CC and got some 14-16 ga spade connectors.

I put on a female spade connector, put some Teflon tape on the sender unit's threads and installed it. Started the truck and gauge in the dash read 0. I decided to test the sender. I grounded a test light on the battery, touched the light to the brass connector on the new sender looking for a dim light at idle and got nothing.

I did some more research on mud and found old threads with people saying to not use Teflon tape since OEM senders ground through their threads to the engine. But the FSM does say to use “sealant” on the threads and the old sender definitely had some sort of old sealant on it. So I took the new sender out, cleaned the threads, reinstalled and still the gauge read 0.

Then I tried to rule out a grounding issue somewhere else. I connected a test light from the battery to the spade connector I had installed and the gauge went full tilt over H.

Now I’m confused. My neighbor helping me delicately slips my new spade connector onto the new sender unit while the truck is idling and the gauge works properly. I think “WTF?” and reach in to grab the spade connector to feel how he put it on the sender, and then the signal to the dash went out and gauge dropped back to 0.

So now I assume it’s a problem with the spade connector I put on. So I removed the spade connector, start the truck, touch the stripped wire to the connector on the new sender unit and gauge in the dash reads 0.

With the new sending unit still installed and wires not connected, I connected a test light from the battery and tested for a ground on the housing of the sending unit and the brass threads and got a bright light. This makes me think the sending unit is grounding properly.

I try to go back to step 1 by reinstalling the old sending unit and touching the stripped wire to the broken connector, but the gauge now reads 0. I test for a ground and it is grounding properly. So now I’m worried I burned out the gauge in my dash. So I connect the test light to the battery and touch the stripped wire, and the gauge moved. So my gauge shouldn’t be burned out.

I am very confused what to try next. It seems like my gauge in my dash is working, my wiring is good, and the new sender is grounding properly. And I have removed the possibility of a bad spade connector from the equation. Is it possibly my sender unit is bad? Any ideas on what to try next?