Battery: Normal- 12.34V Glow position- 11.63V Back to normal- 12.34....

So we have the battery voltage dropping marginally whenever the glow plugs are activated Greg.

I didn't expect it to drop as much as 0.71V (12.34 - 11.63) but then again 11.63V is not even 1 volt below the battery's nominal rating of 12V. So I don't think these readings indicate a battery problem. Besides - We know that the glow plugs do draw a high current so they are bound to "stress" the battery a little.

I didn't expect it to drop as much as 0.71V (12.34 - 11.63) but then again 11.63V is not even 1 volt below the battery's nominal rating of 12V. So I don't think these readings indicate a battery problem. Besides - We know that the glow plugs do draw a high current so they are bound to "stress" the battery a little....Glow Relay: Left Connection- 0V- 10.88V- 0V

Center Connection- 12.32V- 10.92V- 12.32V

Right Connection- 0V- 9.53V- 0V........

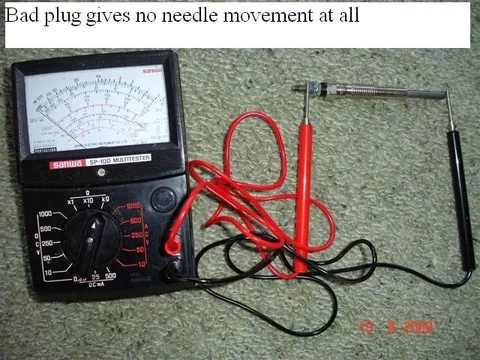

So these are the G, B and S terminals in this photo (of my glow relay):

And they are in the circuit as shown here in Amaurer's diagram:

B is the "battery voltage in" to your relay and is your "centre" reading. It reads 10.92V when you're glowing so there has been a further voltage drop of (11.63 - 10.92) = 0.71V along the wire to your relay. But you've still got near-as-dammit 11V available.

G and S should be reading the same value because they are simply the "voltage out" of your glow relay. (We know that S is connected to nothing-at-all within the relay!) And these are your "left" and "right" readings.

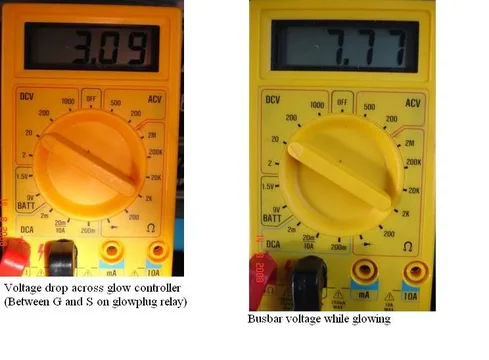

So lets take the average of your 10.88 and 9.53 as your "relay voltage out" reading. This is 10.2V. So the relay is feeding just 10.2V to the wiring to your glow controller.

Now I think this is getting a little LOW! You've lost nearly 2V before even getting to your glow controller.

Glow Controller: Left Side- 10.08 Right Side- 9.38....

OK so the glow controller is getting 10.08 volts. (There's bound to be some discrepancies in readings.) And the glow controller is reducing this voltage to 9.38V due to its resistance (and due to its pitiful attempt at "glowing").

...Plugs From firewall to front: 8.89V- 8.89V- 8.83V- 8.78V- 8.78V- 8.75V (Decreasing V may be from repeated trials)...

So the wiring from the glow controller to the glowplug busbar has dropped the voltage further (from 9.38V down to approx 8.8V lets say)

So where does this leave us?

Yes. Clean terminals/connections as Amaurer/Drew suggests and see if you can reduce your voltage drop.

And perhaps we need to take some readings on our glow systems to compare?

Last edited:

are obviously "the same breed".

are obviously "the same breed".