Vae Victus

Posting more than I know

- Thread starter

- #21

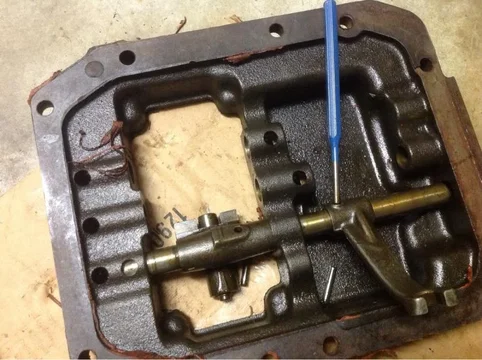

7-B Continued: Counter Shaft Bearings Removal

Well I had a brainstorm today and tried it. Had a puller from AutoZone tool loaner program. The claws were too big to fit but if I ground them down and inserted them sideways, they fit. I could then rotate them into place and screw them back onto the body of the puller.

AZ Loaner no more

Ground off a bit

After grinding a pair I was able to pull the countershaft bearings right off. It made the claws weaker but to enough to be defeated by these bearings.

Puller ready. Input side bearing

Socket used to turn puller

At first it pushed the output bearing out while pulling from the input side, then the input pulled out.

Pushed the output out a bit first

Then Input started coming out

Free at last

Worked on the Output bearing next.

Output

Bearing in 2 parts

Counter Shaft Output side

Had to strap on the 3rd leg to get the input bearing all the way off the shaft once it left the case.

Well I had a brainstorm today and tried it. Had a puller from AutoZone tool loaner program. The claws were too big to fit but if I ground them down and inserted them sideways, they fit. I could then rotate them into place and screw them back onto the body of the puller.

AZ Loaner no more

Ground off a bit

After grinding a pair I was able to pull the countershaft bearings right off. It made the claws weaker but to enough to be defeated by these bearings.

Puller ready. Input side bearing

Socket used to turn puller

At first it pushed the output bearing out while pulling from the input side, then the input pulled out.

Pushed the output out a bit first

Then Input started coming out

Free at last

Worked on the Output bearing next.

Output

Bearing in 2 parts

Counter Shaft Output side

Had to strap on the 3rd leg to get the input bearing all the way off the shaft once it left the case.

Last edited: