Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flexy Coils and Mathematical Theory for Review

- Thread starter Delancy

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?I can't add to the suspension work, but if you really need the weight at each wheel, you can get by with a smaller scale.

Use a beam with the wheel at the center of the beam, and one end of the beam on the scale other end on a solid support, beam as level as possible. The scale weight will be half of actual weight at the wheel.

Use a beam with the wheel at the center of the beam, and one end of the beam on the scale other end on a solid support, beam as level as possible. The scale weight will be half of actual weight at the wheel.

sleeoffroad

Supporting Vendor

I am so confused as to what you are trying to do now. Maybe one should take a simpler approach.

1. Do you like the ride?

2. You want to lower in 2" in the rear, 1" in the front?

3. Suppose you do cut 1" and 2" of the free length of the coils, your concern is that you now have shocks that are 1" and 2" too long on extension.

Solution, cut the coils, weld spring retainers to the bottom and make a bolt in solution for the top. That is really easy to do. So when you droop the axle out, it will do one of two things. One, keep the spring from falling out, two introduce some negative spring rate the helps in getting the body stable.

You are putting way to much emphasis on that last little bit of droop. Believe me, we did what you did a long time ago and it does not work well on the trail. There is no way that spring exerts enough pressure at the last 2" of it's extension to make difference in traction.

Think about it, the natural tendency is for the spring to push the body away from the axles. When on uneven terrain, and the body is not level, then tendency is for the body to unload vs the axle to be pushed down. This makes for sucky wheeling.

This is a truck that could max out our ramp at the shop and have all 4 wheels on the ground. Call Ben and ask him how he liked wheeling that truck.

You can see more pictures here:

http://sleeoffroad.com/trails/moab_2002_spring/moab2002.htm

Further more, it rear steered like a mofo due to the short links in the rear.

In the pic below the truck had 2.5" OME lift springs, with 2" spacers. 26" travel shocks with both front and rear upper shock mounts extended about 4" so that we could fit the compressed length at the lower height. As far as stability, the ShortBus was may more stable than Ben's truck. Helped that it did not have the fat body to make the truck unload when off camber / climbing angled rocks.

I probably went through one set of springs per year due to coil bind with the setup and the springs loosing their spring rate, but overall I was very happy with how the suspension worked with stock links etc. What I did not like was broken stuff and eventually the steering that simply did not work anymore.

1. Do you like the ride?

2. You want to lower in 2" in the rear, 1" in the front?

3. Suppose you do cut 1" and 2" of the free length of the coils, your concern is that you now have shocks that are 1" and 2" too long on extension.

Solution, cut the coils, weld spring retainers to the bottom and make a bolt in solution for the top. That is really easy to do. So when you droop the axle out, it will do one of two things. One, keep the spring from falling out, two introduce some negative spring rate the helps in getting the body stable.

You are putting way to much emphasis on that last little bit of droop. Believe me, we did what you did a long time ago and it does not work well on the trail. There is no way that spring exerts enough pressure at the last 2" of it's extension to make difference in traction.

Think about it, the natural tendency is for the spring to push the body away from the axles. When on uneven terrain, and the body is not level, then tendency is for the body to unload vs the axle to be pushed down. This makes for sucky wheeling.

This is a truck that could max out our ramp at the shop and have all 4 wheels on the ground. Call Ben and ask him how he liked wheeling that truck.

You can see more pictures here:

http://sleeoffroad.com/trails/moab_2002_spring/moab2002.htm

Further more, it rear steered like a mofo due to the short links in the rear.

In the pic below the truck had 2.5" OME lift springs, with 2" spacers. 26" travel shocks with both front and rear upper shock mounts extended about 4" so that we could fit the compressed length at the lower height. As far as stability, the ShortBus was may more stable than Ben's truck. Helped that it did not have the fat body to make the truck unload when off camber / climbing angled rocks.

I probably went through one set of springs per year due to coil bind with the setup and the springs loosing their spring rate, but overall I was very happy with how the suspension worked with stock links etc. What I did not like was broken stuff and eventually the steering that simply did not work anymore.

- Thread starter

- #164

Will address and question your entire post, but in parts, since I talk more than iPhone connectivity will allow.

You're assuming I'm not.

The original intent of thread was to determine what info I could relay to the original coil provider to either:

a.) level with new rear coils or

b.) lower the rear 2" and front 1" with four new coils.

Considering the discrepancy between what I received and what I requested, (being " 4" level lift on lightweight build" requested, yet a 5" front and 6" rear resulted) the reason for thread was to establish values I could relay to AUS coil provider to achieve what I wanted.

As for what I WAS trying to achieve of late:

I was trying replicate the "Flexy" coil properties, being the ability to expand without falling out of the bucket, lift level at 4", from an domestic produce to avoid ordering another set of Flexy's with unknown results and at considerable expense.

I'm trying. I didn't understand the complexity until recently.

This looked simple, to me.

2" coil rate lift with 2" of lesser rated coils, that'd expand and keep some down force while remaining in the bucket.

MetalCloak does for Heeps. MetalTech did it for the rear of the FJC. Not sure why the conceit is lost on the 80.

Yes and no, but reserve final judgement until after Radflo's install, once they arrive in next day or so.

Here's what I don't like:

**Body Roll**

Could be due to the lift height, could be due to the current shocks, could be due to the OE sway's inability to properly mitigate, as oriented on the lifted rear.

**Ass End Elevating during braking or declines**

Could be due to unleveled stance on road, could be due to shocks, could be due to a piss poor braking proportioning.

On one descent, it hopped up enough that I lost all braking (after loosing all steering) and the best I can surmise, I must've sucked in air from the top of the master.

Not all the fault of the coils, granted, but an example. When declining, the ass end unloads and I can loose all traction easily, so the only resistance afforded is from the front axle.

The body roll will be addressed, covertly, with sway modifications. If it works then I'll be the first to exclaim. If it doesn't, I'll keep at it until it does.

The back end hopping, I'm hoping, can be minimized with a lesser lifted rear end. There's nothing more I can see that can be done to the braking system, after considerable expense, replacing every single component thereof.

Yes. That's what I wanted from the onset. 4" lift with willingness to cut sheet metal to free real estate for 37s.

I'm past worrying about shock lengths. I have limit straps, if need be.

The coils gradually increase in rate, I assume, more pronounced during the upper 3 wraps, but a increase of .20-.25" through the lower, heavier wraps.

The PS coil, which is tagged at 15mm shorter than DS, actually has a longer extended length and greater variations of bar thickness throughout the first 5-7 coils.

I can't see how I can cut without furthering the issues. Say I cut to much, since its not easy to replicate the weight on a bench and know how static height will change, then what? Spacers?

How do you determine how much to cut when every coil is not only a different tagged length, but the few lengths make no sense, as the lesser tags are actually longer?

The best tangible solution that I can grasp at this point is to put same producers tagged 555s in the rear, and 575s in the front for ~4" at all corners, then space in 15mm increments DS to PS to de-lean, based on the observations previously be mentioned regarding the tagged part number and the affect it had on static height.

Not because it's the best way to achieve a dual rate spring, but because its the only way I can understand the numbers and relay.

Should've gone coilovers.

I am so confused as to what you are trying to do now.

You're assuming I'm not.

The original intent of thread was to determine what info I could relay to the original coil provider to either:

a.) level with new rear coils or

b.) lower the rear 2" and front 1" with four new coils.

Considering the discrepancy between what I received and what I requested, (being " 4" level lift on lightweight build" requested, yet a 5" front and 6" rear resulted) the reason for thread was to establish values I could relay to AUS coil provider to achieve what I wanted.

As for what I WAS trying to achieve of late:

I was trying replicate the "Flexy" coil properties, being the ability to expand without falling out of the bucket, lift level at 4", from an domestic produce to avoid ordering another set of Flexy's with unknown results and at considerable expense.

Maybe one should take a simpler approach.

I'm trying. I didn't understand the complexity until recently.

This looked simple, to me.

2" coil rate lift with 2" of lesser rated coils, that'd expand and keep some down force while remaining in the bucket.

MetalCloak does for Heeps. MetalTech did it for the rear of the FJC. Not sure why the conceit is lost on the 80.

1. Do you like the ride?

Yes and no, but reserve final judgement until after Radflo's install, once they arrive in next day or so.

Here's what I don't like:

**Body Roll**

Could be due to the lift height, could be due to the current shocks, could be due to the OE sway's inability to properly mitigate, as oriented on the lifted rear.

**Ass End Elevating during braking or declines**

Could be due to unleveled stance on road, could be due to shocks, could be due to a piss poor braking proportioning.

On one descent, it hopped up enough that I lost all braking (after loosing all steering) and the best I can surmise, I must've sucked in air from the top of the master.

Not all the fault of the coils, granted, but an example. When declining, the ass end unloads and I can loose all traction easily, so the only resistance afforded is from the front axle.

The body roll will be addressed, covertly, with sway modifications. If it works then I'll be the first to exclaim. If it doesn't, I'll keep at it until it does.

The back end hopping, I'm hoping, can be minimized with a lesser lifted rear end. There's nothing more I can see that can be done to the braking system, after considerable expense, replacing every single component thereof.

2. You want to lower in 2" in the rear, 1" in the front?

Yes. That's what I wanted from the onset. 4" lift with willingness to cut sheet metal to free real estate for 37s.

3. Suppose you do cut 1" and 2" of the free length of the coils, your concern is that you now have shocks that are 1" and 2" too long on extension.

I'm past worrying about shock lengths. I have limit straps, if need be.

The coils gradually increase in rate, I assume, more pronounced during the upper 3 wraps, but a increase of .20-.25" through the lower, heavier wraps.

The PS coil, which is tagged at 15mm shorter than DS, actually has a longer extended length and greater variations of bar thickness throughout the first 5-7 coils.

I can't see how I can cut without furthering the issues. Say I cut to much, since its not easy to replicate the weight on a bench and know how static height will change, then what? Spacers?

How do you determine how much to cut when every coil is not only a different tagged length, but the few lengths make no sense, as the lesser tags are actually longer?

The best tangible solution that I can grasp at this point is to put same producers tagged 555s in the rear, and 575s in the front for ~4" at all corners, then space in 15mm increments DS to PS to de-lean, based on the observations previously be mentioned regarding the tagged part number and the affect it had on static height.

Not because it's the best way to achieve a dual rate spring, but because its the only way I can understand the numbers and relay.

Should've gone coilovers.

ChaseTruck

--

@ Slee: pic #2 - interesting how different Rocker Knocker looks these days.

@ Delancy: the rear hopping - too much (primary...) spring rate, and not enough shock?

@ Delancy: the rear hopping - too much (primary...) spring rate, and not enough shock?

sleeoffroad

Supporting Vendor

Considering the discrepancy between what I received and what I requested, (being " 4" level lift on lightweight build" requested, yet a 5" front and 6" rear resulted) the reason for thread was to establish values I could relay to AUS coil provider to achieve what I wanted.

Herein lies the rub. I have found out a long time ago that light, heavy, medium does not mean squat, but that is what people want to hear and use. Take your truck to you local truck stop, park it so that it is on two pads and weigh the front and rear. Cost $10 or so. With that info, you should be able to get spring manufacturer to get it dialed in better.

I was trying replicate the "Flexy" coil properties, being the ability to expand without falling out of the bucket, lift level at 4", from an domestic produce to avoid ordering another set of Flexy's with unknown results and at considerable expense.

There is a lot of trial and error in this and I can assure you that it is going to cost you dearly to get a set that you would be happy with finally. Also, we recently helped Darren from Autocraft build his US trucks. What became apparent out of this is the Ozzie's and us like trucks completely different. He has built a slinky truck here the way they have them set up in Australia and it is polar opposite to what we do in terms of how the truck rides. Unfortunately the truck is in the back of the shop with a blow headgasket, otherwise I would have told you to come over here and drive it.

MetalCloak does for Heeps. MetalTech did it for the rear of the FJC. Not sure why the conceit is lost on the 80.

Huge weight difference is what causes the issues. We have built flexy coil trucks, tall trucks with ridiculously tall coils and long shocks. Finally we have settled on what we use for our 6" an 4" lift springs and we are happy with it. Also one of the main reasons we abandoned the OME J spring deal with spacers. Simply too much body roll and the trucks became unstable.

Yes and no, but reserve final judgement until after Radflo's install, once they arrive in next day or so.

A lot of ride is in the shocks, so yes, I would like to hear what you say when you get those on. But inherently if you have soft flexy springs, you are gong to need good shocks to control the heavy truck.

**Body Roll**

There are may ways to get this right. If there is anyone in your area with a truck with our 4" lift go drive it. Yes, it does not have the massive droop etc etc that the fancy slinky shocks/spring have, but I can assure you it drives well on and off road.

Could be due to the lift height, could be due to the current shocks, could be due to the OE sway's inability to properly mitigate, as oriented on the lifted rear.

Yes, you have to pick your poison and then dial it in.

**Ass End Elevating during braking or declines**

Could be due to unleveled stance on road, could be due to shocks, could be due to a piss poor braking proportioning.

Are you referring to unloading. Again where the negative spring rate (pulling the spring apart) with short springs and retainers really work well.

On one descent, it hopped up enough that I lost all braking (after loosing all steering) and the best I can surmise, I must've sucked in air from the top of the master.

Not all the fault of the coils, granted, but an example. When declining, the ass end unloads and I can loose all traction easily, so the only resistance afforded is from the front axle.

This is the side effect of building what we call a floppy jallopy.

The body roll will be addressed, covertly, with sway modifications. If it works then I'll be the first to exclaim. If it doesn't, I'll keep at it until it does.

I am interested to see what you come up with.

Yes. That's what I wanted from the onset. 4" lift with willingness to cut sheet metal to free real estate for 37s.

I think the disconnect came from actual weight vs perceived weight (light, medium heavy). This is between you and the spring suppler and I can see this is what started all this and now trying to resolve.

I'm past worrying about shock lengths. I have limit straps, if need be.

As long as you make sure you don't over compress.

The coils gradually increase in rate, I assume, more pronounced during the upper 3 wraps, but a increase of .20-.25" through the lower, heavier wraps.

The PS coil, which is tagged at 15mm shorter than DS, actually has a longer extended length and greater variations of bar thickness throughout the first 5-7 coils.

I can't see how I can cut without furthering the issues. Say I cut to much, since its not easy to replicate the weight on a bench and know how static height will change, then what? Spacers?

I would start by cutting 1" off the rear free height. See where you end up with. My guess is, even if you have to throw the spring away finally, you are better off than trying to have your own made. you will learn a lot and maybe even end up with something that works.

[/quote]

How do you determine how much to cut when every coil is not only a different tagged length, but the few lengths make no sense, as the lesser tags are actually longer? [/quote]

Not sure, but it is trial and error. If you are more comfortable, start with 1/2" of each.

The best tangible solution that I can grasp at this point is to put same producers tagged 555s in the rear, and 575s in the front for ~4" at all corners, then space in 15mm increments DS to PS to de-lean, based on the observations previously be mentioned regarding the tagged part number and the affect it had on static height.

Not because it's the best way to achieve a dual rate spring, but because its the only way I can understand the numbers and relay.

Should've gone coilovers.

My advise, put the Radflo's on it, keep it at the height you have and go wheel the piss out of it. You will be happy with the additional height. Save your money for the axles and steering that you will have to do in any case. Or save the money for the buggy where you will eventually end up with

- Thread starter

- #167

Once again, you're quicker than I, but I typed all this chit on Iphone, so throwing it out there, however irrelevant.

Trying to maximize the potential, even though I know most real situations may not require. Didn't realize that I overemphasized any one aspect. All are equal.

I'm in no position to discount your experience, as you and everyone else well knows.

I've said many times that I should've listened to conventional wisdom, but I didn't.

Should've taken yours and LTs advise and kept it simple, but I didn't.

It is what it is.

Here's all I "know" and basis for this endeavor, long before getting to this point.

All MetalTech's stuff.

An identically rear linked FJC with ~2" of "lift" has a similar coil that can use 11" travel shocks (4" up, 7" down, 28.5" extended). 35" tire calculated.

It uses almost every inch of and does a good job of pushing the front around in situations that the front needs help.

Now, for the 80, with 4" of lift, with a 2" larger diameter tire, you'd think a similar ratio, function, and result would be possible.

Track width is slightly narrower, but I'd bet I could swap links and panhard from one to another, without much variance (have OE at home for both, so probably need to confirm before shooting my mouth off, but similar, nonetheless). Wheel base is dissimilar, but if factoring the weight distribution, adjusting for slightly shorter 120, the weight and instability resulting logically appear close enough for the comparison.

I'm not too far off from that, with the 80.

760mm (30") extended

450mm (17.75") compressed

290mm (12.25") shock travel

The 1 1/2" is attributable to the additional 2" of lift (considering a 4", not the 6" I have)

Have tried to replicate, what I think is a proven performer. Not only do I think that, but several other FJC owners, LT, and Mark think that, as well.

Did we all miss something?

Asked earnestly, not a smart ass, baited question.

(Because I already read the reply, will add:

Posted curb weight on FJC 4,050 lbs. As it sits now, I'm at 4,660lbs, after a dramatic diet.

Best a Google query resulted on an LX450 was 4,834lbs. I can only guess what weight I've added in SE Arms and Tires alone, but unsprung.)

You are putting way to much emphasis on that last little bit of droop.

Trying to maximize the potential, even though I know most real situations may not require. Didn't realize that I overemphasized any one aspect. All are equal.

Believe me, we did what you did a long time ago and it does not work well on the trail. There is no way that spring exerts enough pressure at the last 2" of it's extension to make difference in traction.

I'm in no position to discount your experience, as you and everyone else well knows.

I've said many times that I should've listened to conventional wisdom, but I didn't.

Should've taken yours and LTs advise and kept it simple, but I didn't.

It is what it is.

Here's all I "know" and basis for this endeavor, long before getting to this point.

All MetalTech's stuff.

An identically rear linked FJC with ~2" of "lift" has a similar coil that can use 11" travel shocks (4" up, 7" down, 28.5" extended). 35" tire calculated.

It uses almost every inch of and does a good job of pushing the front around in situations that the front needs help.

Now, for the 80, with 4" of lift, with a 2" larger diameter tire, you'd think a similar ratio, function, and result would be possible.

Track width is slightly narrower, but I'd bet I could swap links and panhard from one to another, without much variance (have OE at home for both, so probably need to confirm before shooting my mouth off, but similar, nonetheless). Wheel base is dissimilar, but if factoring the weight distribution, adjusting for slightly shorter 120, the weight and instability resulting logically appear close enough for the comparison.

I'm not too far off from that, with the 80.

760mm (30") extended

450mm (17.75") compressed

290mm (12.25") shock travel

The 1 1/2" is attributable to the additional 2" of lift (considering a 4", not the 6" I have)

Have tried to replicate, what I think is a proven performer. Not only do I think that, but several other FJC owners, LT, and Mark think that, as well.

Did we all miss something?

Asked earnestly, not a smart ass, baited question.

(Because I already read the reply, will add:

Posted curb weight on FJC 4,050 lbs. As it sits now, I'm at 4,660lbs, after a dramatic diet.

Best a Google query resulted on an LX450 was 4,834lbs. I can only guess what weight I've added in SE Arms and Tires alone, but unsprung.)

- Thread starter

- #168

@ Delancy: the rear hopping - too much (primary...) spring rate, and not enough shock?

I don't know, but you may recall the brake bedding performed after Claudia said something about?

I didn't elude to this, but left skid marks and not on the pavement.

I'm betting the new shocks will combat, to some degree. Considering there's only an inch left in the OME Ls at ride height, the extension of the Radflo's may reduce on road. For sure off, because the shocks top very quickly, as seen here.

http://youtu.be/YEhT3JeyBF0

Yes, dumb, but for illustrative purposes.

sleeoffroad

Supporting Vendor

Trying to maximize the potential, even though I know most real situations may not require. Didn't realize that I overemphasized any one aspect. All are equal.

This is the bottom line. Yes if you like tinkering that is one thing, but it sounds like you are getting frustrated with it. Just go wheel it.

An identically rear linked FJC with ~2" of "lift" has a similar coil that can use 11" travel shocks (4" up, 7" down, 28.5" extended). 35" tire calculated.

It uses almost every inch of and does a good job of pushing the front around in situations that the front needs help.

What does "use it mean". Yes it uses all available travel, but does it really make it wheel better? Think about this, when the spring can cause the system to expand and the shocks is really long, what has more resistance, the ground or the body in air? That is what causes the unloading when the body is in a position that gravity aids in the unloading. I have seen tons of "slinky" trucks on the trail and in most cases they sucked and were uncomfortable to drive.

Yes, you probably could, but what do you gain? Once the links cause so much rear steer in the back that you can not keep the truck on the line you want it to go it becomes a PITA to wheel.Now, for the 80, with 4" of lift, with a 2" larger diameter tire, you'd think a similar ratio, function, and result would be possible.

Did we all miss something?

Asked earnestly, not a smart ass, baited question.

Probably not, but I am just trying to give some info from someone that pushed the 80 drivetrain as far as I could and honestly the suspension was not the thing that sideline me in the end. That is why I would not over think the suspension.

(Because I already read the reply, will add:

Posted curb weight on FJC 4,050 lbs. As it sits now, I'm at 4,660lbs, after a dramatic diet.

Only reference I have is that our Limo LX450 weighs 9200 lbs

- Thread starter

- #170

Herein lies the rub. I have found out a long time ago that light, heavy, medium does not mean squat, but that is what people want to hear and use. Take your truck to you local truck stop, park it so that it is on two pads and weigh the front and rear. Cost $10 or so. With that info, you should be able to get spring manufacturer to get it dialed in better.

Total weight was discussed. They stated "light" in the description.

I've not had great success at even the CAT certified scales locally, since the posted variance is 500-600lbs, but will, for fun.

Again, I didn't feel comfortable that a corrected stance was capable, due to the magnitude or ordered/received, so there's a vast difference in AUS/US GVWs. Purpose of original topic was requesting how to go about describing/ordering the replacement coils from same producer.

There is a lot of trial and error in this and I can assure you that it is going to cost you dearly to get a set that you would be happy with finally.

Agree on both points, the latter with severe dread.

Seems I'll wind up with a total of 10 coils just to get 4 that may work.

Also, we recently helped Darren from Autocraft build his US trucks.

I hold him responsible for this mess.

If I hadn't been enamored with his 3" slinkied, 37" 80, I wouldn't be in this position.

What became apparent out of this is the Ozzie's and us like trucks completely different.

Here's the irony to that statement. Look at LCs as a whole.

Where do the components come from that probably have 75-85% of the suspension market share originate?

Another factor when deciding to go across the pond for this stuff. Figured they had insight into the platform, considering every major player is in OZ.

Unfortunately the truck is in the back of the shop with a blow headgasket, otherwise I would have told you to come over here and drive it.

Throw a 2UZ in it and I'll drive my up to leave for similar.

Huge weight difference is what causes the issues. Simply too much body roll and the trucks became unstable.

Why I thought the 3" was mo betta, and why I think 4" is what I'd really like to attempt to do.

Lower and planted.

A lot of ride is in the shocks, so yes, I would like to hear what you say when you get those on.

I just hope Glenn understood Denglish. If not, and there's not an improvement in overall feel, will be able to, in laymen's terms, hopefully describe the undesired characteristics that still remain.

This is the side effect of building what we call a floppy jallopy.

My concern from the onset.

My advise, put the Radflo's on it, level it to front's height, 2UZ, Hi 9, high steer, hydro assist.....

Fixed. When are you starting?

Or save the money for the buggy where you will eventually end up with

Oh, I may have gone and screwed this up already, in a pig way.....1d 10h remains to be determined.

I'm just not a buggy, nor a resto guy.

Has to be street-able in road worthy manners, not too nice to use as intended, at the same time.

- Thread starter

- #171

Here it is in a nutshell.

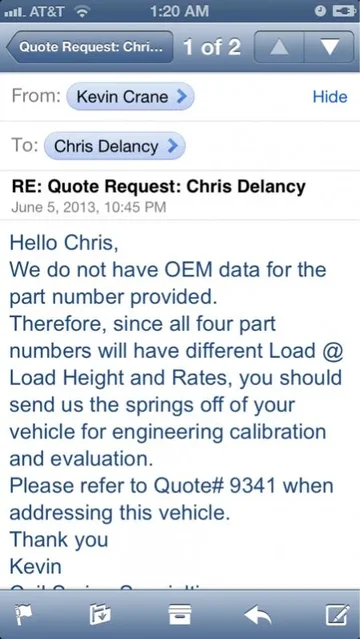

Obviously, I value your opinion and I've listened to every aspect, this far, but for purpose of brevity (bahahahaha) this is what's been presented by Eliot at SS, knowing that, at the absolute minimum, I'd like it level.

Quote-

"Hi Chris

If your happy to keep the overall height at roughly 5" we could lower the rear by swapping the passenger side coil to the driver side and send over a single coil that is slightly shorter to put back into the passenger side. To drop it down to 4" all round we'd have to change the coils to FLEXTR555 on the rear and FLEXTF-575/575 on the front"

-End Quote.

My reply

Quote-

"At this point, I'd like a quote to do both, freight to NSW.

I'd like (2) coils to lower the rear quoted, whatever one you're singly suggesting here, plus the next size down. Then I can play around to get a front and rear 5" lift.

I'd also like (4) coils that would lower all four corners to 4".

Should be a total of (6) coils on the quote."

-End Quote.

All quoted at a reasonably reduced price, the added advantage having a buddy in NSW that's in the freight business.

Here's the one question I have and it can be the proverbial debate ender.

If maintaining the front at it's current height, does a single coil swap, as Eliot suggested (15mm lower) seem close enough, or would it make more sense to get both (1) 15mm shorter and (1) 30mm shorter, based on all the crap discussed so far?

Assume an outlay of $245 per coil, when all's said and done.

Obviously, I value your opinion and I've listened to every aspect, this far, but for purpose of brevity (bahahahaha) this is what's been presented by Eliot at SS, knowing that, at the absolute minimum, I'd like it level.

Quote-

"Hi Chris

If your happy to keep the overall height at roughly 5" we could lower the rear by swapping the passenger side coil to the driver side and send over a single coil that is slightly shorter to put back into the passenger side. To drop it down to 4" all round we'd have to change the coils to FLEXTR555 on the rear and FLEXTF-575/575 on the front"

-End Quote.

My reply

Quote-

"At this point, I'd like a quote to do both, freight to NSW.

I'd like (2) coils to lower the rear quoted, whatever one you're singly suggesting here, plus the next size down. Then I can play around to get a front and rear 5" lift.

I'd also like (4) coils that would lower all four corners to 4".

Should be a total of (6) coils on the quote."

-End Quote.

All quoted at a reasonably reduced price, the added advantage having a buddy in NSW that's in the freight business.

Here's the one question I have and it can be the proverbial debate ender.

If maintaining the front at it's current height, does a single coil swap, as Eliot suggested (15mm lower) seem close enough, or would it make more sense to get both (1) 15mm shorter and (1) 30mm shorter, based on all the crap discussed so far?

Assume an outlay of $245 per coil, when all's said and done.

- Thread starter

- #172

Thread was started 6 days ago and has 3,295 views.

Page six is the first topic specific thread I come to with more @ 9700 on the ARB DRL modification, started first of Feb.

There has to be credence for, at least, a desire for a similarly performing product that I can't see how it'd go unnoticed by vendors.

Either that, or watching a meltdown is just fun.....

Forgot what the website looks like from laptop.

Page six is the first topic specific thread I come to with more @ 9700 on the ARB DRL modification, started first of Feb.

There has to be credence for, at least, a desire for a similarly performing product that I can't see how it'd go unnoticed by vendors.

Either that, or watching a meltdown is just fun.....

Forgot what the website looks like from laptop.

sleeoffroad

Supporting Vendor

Either that, or watching a meltdown is just fun.....

Yup, that is it

View does not necessarily translate to $'s. Learned that a long time ago.

most certainly the "melt down" for me, I like to suffer in silence so it's therapeutic to see you "put it all out there"

Thread was started 6 days ago and has 3,295 views.

Page six is the first topic specific thread I come to with more @ 9700 on the ARB DRL modification, started first of Feb.

There has to be credence for, at least, a desire for a similarly performing product that I can't see how it'd go unnoticed by vendors.

Either that, or watching a meltdown is just fun.....

Forgot what the website looks like from laptop.

I get what your after and I'm interested in something similar. Your wife must be a saint though or you have separate bank accounts. Either way, stay focused and good luck.

- Thread starter

- #176

Yup, that is it

most certainly the "melt down" for me

Thanks for the votes of confidence.

View does not necessarily translate to $'s. Learned that a long time ago.

As for me, wanted what I wanted, just not capable of creation if it doesn't exist.

I know the real reason why it doesn't exist, and that all boils down to $$$, not wether or not it can be achieved.

Your wife must be a saint

She's busy competing with Imelda Marcos, and her angelic qualities have no bearing on bank accounts, as long as they're working.

- Thread starter

- #177

View does not necessarily translate to $'s.

Just not on the 80 boards.

Here's the principle I've worked under after being similarly advised about five months before initiation of thread, with following content, when purchasing this "kit":

(Not an example if anything more than viability, since it's been questioned)

It is always advantageous to have more travel whether it is just the front, rear or both. Being able to have the wheels on the ground at all times will greatly improve traction and the ability to have more control in tough situations.

For a trail truck or rock crawler up travel is not nearly as important as down travel. We had to limit the up travel due to the size of the shock if we could go with a smaller bump stop we would but given the parameters we are making it work to get the 11.5" of shock travel out of the rear. That being said on a trail truck or rock crawler it is all about having your wheels on the ground. If you look at most rock crawlers you will see that they have their up travel set up around 4" and the rest is all down travel using a 14" travel coilover.

Here are photos showing ground height and flexed out with a tape measure with a sway bar.

The official specs on the progressive rate spring is 250lbs on the bottom half and 105lbs on top with a 19.25" free height. When installed on a FJC it gives you a 2" lift and measured out the same as the FJC we had in the shop with OME 2985 springs.

We aren't really in the market for making custom springs and it would require buying 50 sets of them for one production run.

Just one of many happy campers.

Best rear end suspension out there by FAR ,, MT ROCKS

Views:

Most everyone I know is running this.

It's possible.

It's beneficial.

It's marketable.

It's not alchemy.

It's just too expensive for the vocal 80 owners on Mud is what it all boils down to and the reason there isn't similar offered.

Obviously, more lucrative to pull off the shelf components, and I get that, BUT I'm not insane in attempting to replicate similar just because it won't rake in the cash from the 80 crowd.

Edited: In my own defense.

AutoCraft Aus

Araco Master

- Joined

- May 20, 2008

- Threads

- 15

- Messages

- 918

- Location

- Central Victoria, desert region.

- Website

- 4xoaus.com.au

Hey, dont go blaming me for being pedantic

Set up is a wierd one, Christo when he drove a slinky set up said it was boucy, yet the socks were 12% firmer, than OME and spring rate slightly softer, with taller free height, but only about 20-30 lb.

Same coilsvin SNOWY with the icons, much firmer except rebound before adjustment, still thought it was soft.

Shocks have gone back for a valve change, car now needs bigger rear sway bar for rear weight, which makes a huge difference.

Part of my goal is to set SNOWY up, get feedback, then, product becomes available, and Slee can use it for test drives, or when his chevy is broken down, to get to work :whoops:

To stop the rear lift, and help transfer torque to the ground, making the lower rear arms 250mm longer and raise the upper mountings at the diff really helps.

Set up is a wierd one, Christo when he drove a slinky set up said it was boucy, yet the socks were 12% firmer, than OME and spring rate slightly softer, with taller free height, but only about 20-30 lb.

Same coilsvin SNOWY with the icons, much firmer except rebound before adjustment, still thought it was soft.

Shocks have gone back for a valve change, car now needs bigger rear sway bar for rear weight, which makes a huge difference.

Part of my goal is to set SNOWY up, get feedback, then, product becomes available, and Slee can use it for test drives, or when his chevy is broken down, to get to work :whoops:

To stop the rear lift, and help transfer torque to the ground, making the lower rear arms 250mm longer and raise the upper mountings at the diff really helps.

AutoCraft Aus

Araco Master

- Joined

- May 20, 2008

- Threads

- 15

- Messages

- 918

- Location

- Central Victoria, desert region.

- Website

- 4xoaus.com.au

Australia and it is polar opposite to what we do in terms of how the truck rides. Unfortunately the truck is in the back of the shop with a blow headgasket, otherwise I would have told you to come over here and drive it.

save the money for the buggy where you will eventually end up with

Damn, you have pre empted my build thread in my sig line now

Polar opposite to OME maybe in ride,

so far the shock changes we look for have been embraced by the manufacturers, and making them work as well as we would like with opposing panhard rods etc, is part of the aim right now, and why we have invested in a U.S vehicle (apart from tax deductable trips )

ChaseTruck

--

Just a fleeting comment from the peanut gallery, because none of our trail trucks, including the 80, will be anything like what's discussed here. Well, come to think of it, my Blazer can bounce like Mr. D's 80 in that video any day, without even trying very hard  ... but that's because I'm to cheap to spring for the $400 per corner on shocks that it would take ... I'm watching because once our 80 needs to be higher than the current OME 2", I want to know my options...

... but that's because I'm to cheap to spring for the $400 per corner on shocks that it would take ... I'm watching because once our 80 needs to be higher than the current OME 2", I want to know my options...

I find the reference to "rock crawlers" problematic. Some of my rock crawler friends think nothing of e.g. starting with a nice 550lbs Dana 60 that ends up as a 1200lbs front axle after extensive trusses, and whatnot, and water in 42" stickies... Of course, that thing will droop to the max AND stick to the ground. For these guys, all the stuff above the springs appears to be a necessary evil, and they don't care where it hangs, rubs, or leans, as long as the axles are on the ground and the motor doesn't lose oil or fuel pressure. So, the "rock crawler" terminology might not be so useful for a truck that'll see street use.... Just sayin'

... but that's because I'm to cheap to spring for the $400 per corner on shocks that it would take ... I'm watching because once our 80 needs to be higher than the current OME 2", I want to know my options...

... but that's because I'm to cheap to spring for the $400 per corner on shocks that it would take ... I'm watching because once our 80 needs to be higher than the current OME 2", I want to know my options...I find the reference to "rock crawlers" problematic. Some of my rock crawler friends think nothing of e.g. starting with a nice 550lbs Dana 60 that ends up as a 1200lbs front axle after extensive trusses, and whatnot, and water in 42" stickies... Of course, that thing will droop to the max AND stick to the ground. For these guys, all the stuff above the springs appears to be a necessary evil, and they don't care where it hangs, rubs, or leans, as long as the axles are on the ground and the motor doesn't lose oil or fuel pressure. So, the "rock crawler" terminology might not be so useful for a truck that'll see street use.... Just sayin'

Last edited:

Similar threads

- Replies

- 0

- Views

- 323

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)