Well you're committed now, no turning back. You need to understand, by taking the bottom end apart, it's not as simple as bolting everything back down and calling it done. The tolerances in the bottom end are insane. Nothing goes back together 100% the same as it came out, and a small mistake here is the difference between an engine that runs for another 200,000 without issue, or suffers catastrophic failure after 2,000.

In my opinion, now that you're here, don't take any shortcuts. You need to check everything to make sure it's in spec. Live by the FSM. Follow it to the letter. You'll need some tools you might not have if you haven't done bottom end work before. You'll need a dial gauge which can measure both internally and externally, a good set of precision micrometres, piston ring expanders, a thickness gauge, I'd use some plastigauge too (techniques differ here, but the FSM describes using it, so I'd go with it if you're not experienced enough to vary from the official guide). A good torque wrench you trust to be really accurate. More stuff I'm forgetting I'm sure, check the FSM for tools they reference vs what you have.

In terms of parts, you'll need new bearings and thrust washers. No point trying to reuse them with where you are now, and you need to make sure they're matched to your clearances if there's some wear on the crankshaft. You'll need new pistons, piston rings, oil seals. I'd personally replace all the bolts too just because, but you could probably reuse them.

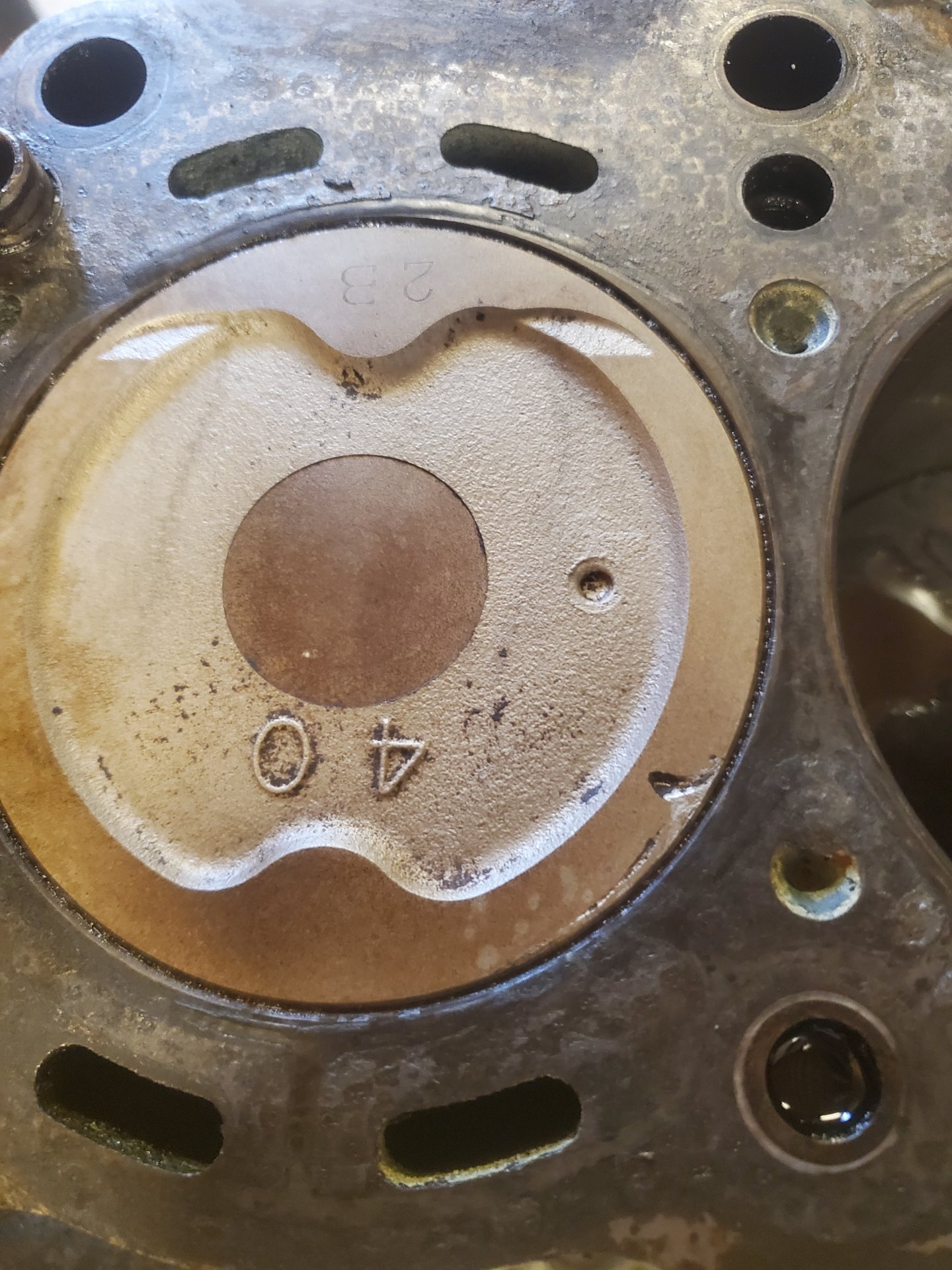

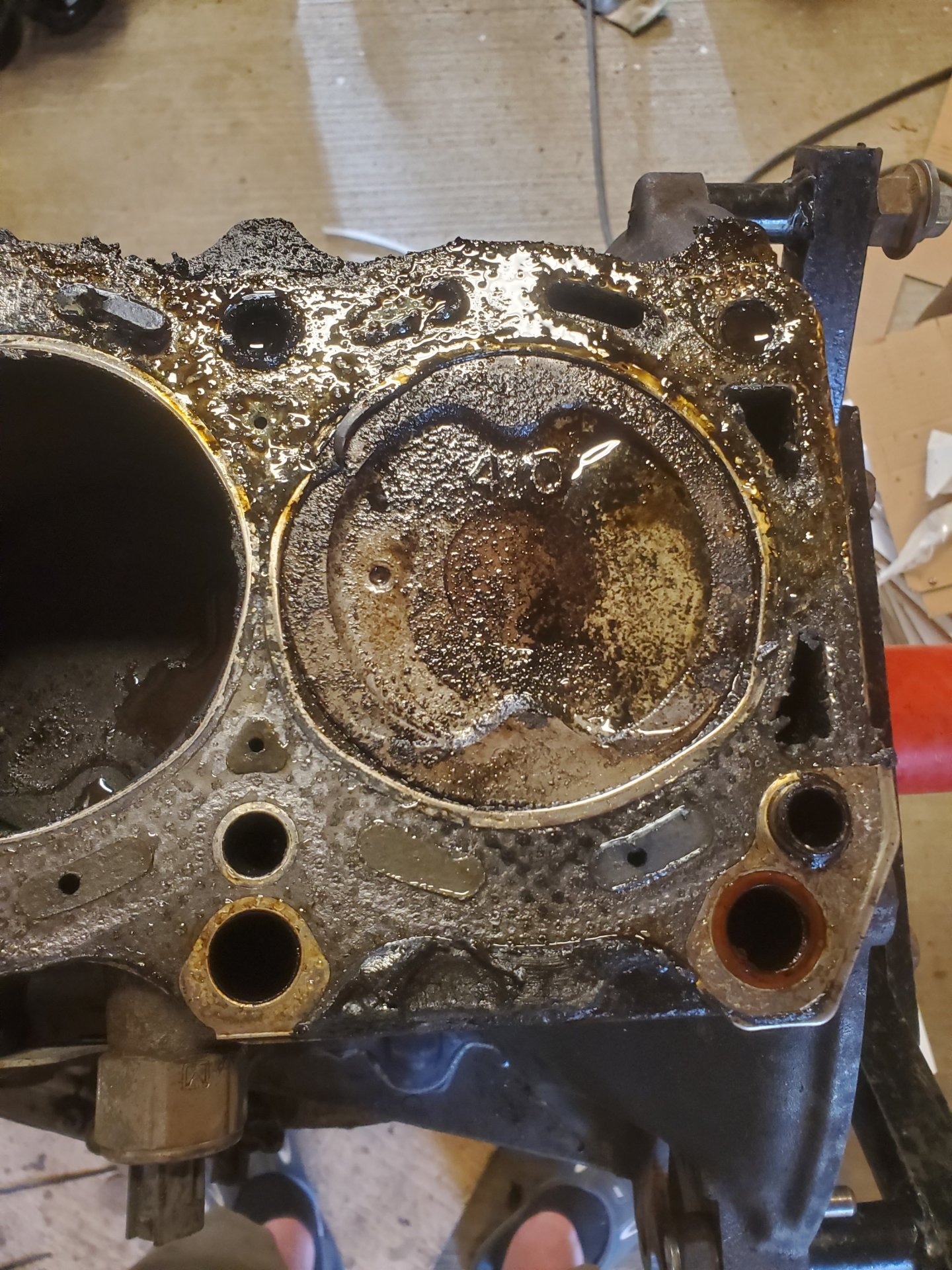

For your procedure, make sure you 100% don't mix up the order or direction of anything. I personally would have put matchmarks on everything before disassembly. You might want to go back and mark them with something now, to make sure if things get knocked over or mixed up, there's no way you'll ever lose track of order and orientation. You should lubricate everything, especially the working surfaces, so that there's no chance of any rust forming before reassembly. You need to have a very clean work area for the final assembly, as you don't want any grit whatsoever to get onto the working surfaces.

Don't rush. Take your time. You should expect to be working on this for months now. Quadruple check everything and go slow and careful, and you can do this, but this is absolutely the most precise, most important part of the entire vehicle. Treat it with care and respect.