in my case I have a CDL switch so I was able to lock it without going into low range. However, the same thing can be done with BILT4ME's instructions pulling the Diff fuse. we drove on the freeway several times like this and even some fire roads. it handles slightly different without the front wheels driving, but like I said, was just like the 60 series.Doing this would also mean I would have to drive around in Low though correct? Maybe fine for driving around the neighborhood but not really useful to go over 20-25mph. Or am I missing something? Or would this be in addition to BILT4ME's instructions above that would allow me to put the transfer case back in high?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Busted Transfer Case

- Thread starter kjkruer

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Where did you get them? Seems like something that people might want to keep in their spares box.plus installed some 3d printed splineless drive flanges

I have an extra set of drive flanges. some newish ones and some factory ones. last year I installed a part time kit from cruiser parts. so I have some extra flanges. let me know if your interested.

I drew them up and printed them, they turned out very nice if I say so myself. I'd be open to printing more for those interested.Where did you get them? Seems like something that people might want to keep in their spares box.

I may be interested in a spare flange if the OP is not.I have an extra set of drive flanges. some newish ones and some factory ones. last year I installed a part time kit from cruiser parts. so I have some extra flanges. let me know if your interested.

mudgudgeon

Resident galah

Doing this would also mean I would have to drive around in Low though correct? Maybe fine for driving around the neighborhood but not really useful to go over 20-25mph. Or am I missing something? Or would this be in addition to BILT4ME's instructions above that would allow me to put the transfer case back in high?

Yes, you missed something.

Put transfer into low range. Transfer automatically locks the centre diff lock.

Pull diff lock fuse out. This disabled the centre diff lock actuator.

Shift tcase to high. Centre diff lock stays locked.

Remove front drive shaft. 4x14mm bolts at each end.

Remove drive flanges from the front hubs.

Use tape to do your best to tape up the end of the hub to keep dust out.

You now have rear wheel drive only.

I've personally driven an 80 like this for months at a time

Drive flange failure is common on the 93/94 models with the short spline birfields. If that’s the case I have 2 new flanges if you are interested.

- Thread starter

- #27

Mine is a 96. Unfortunately it’s gonna be after the holidays before I get some time to get out there and get it pulled apart to see exactly what I need to replace. Thanks for all the help from everyone.Drive flange failure is common on the 93/94 models with the short spline birfields. If that’s the case I have 2 new flanges if you are interested.

I think this has been said but don't drive it around with a potentially broken birfield. You will chew up the knuckle ball and your steering could also lock up.

- Thread starter

- #29

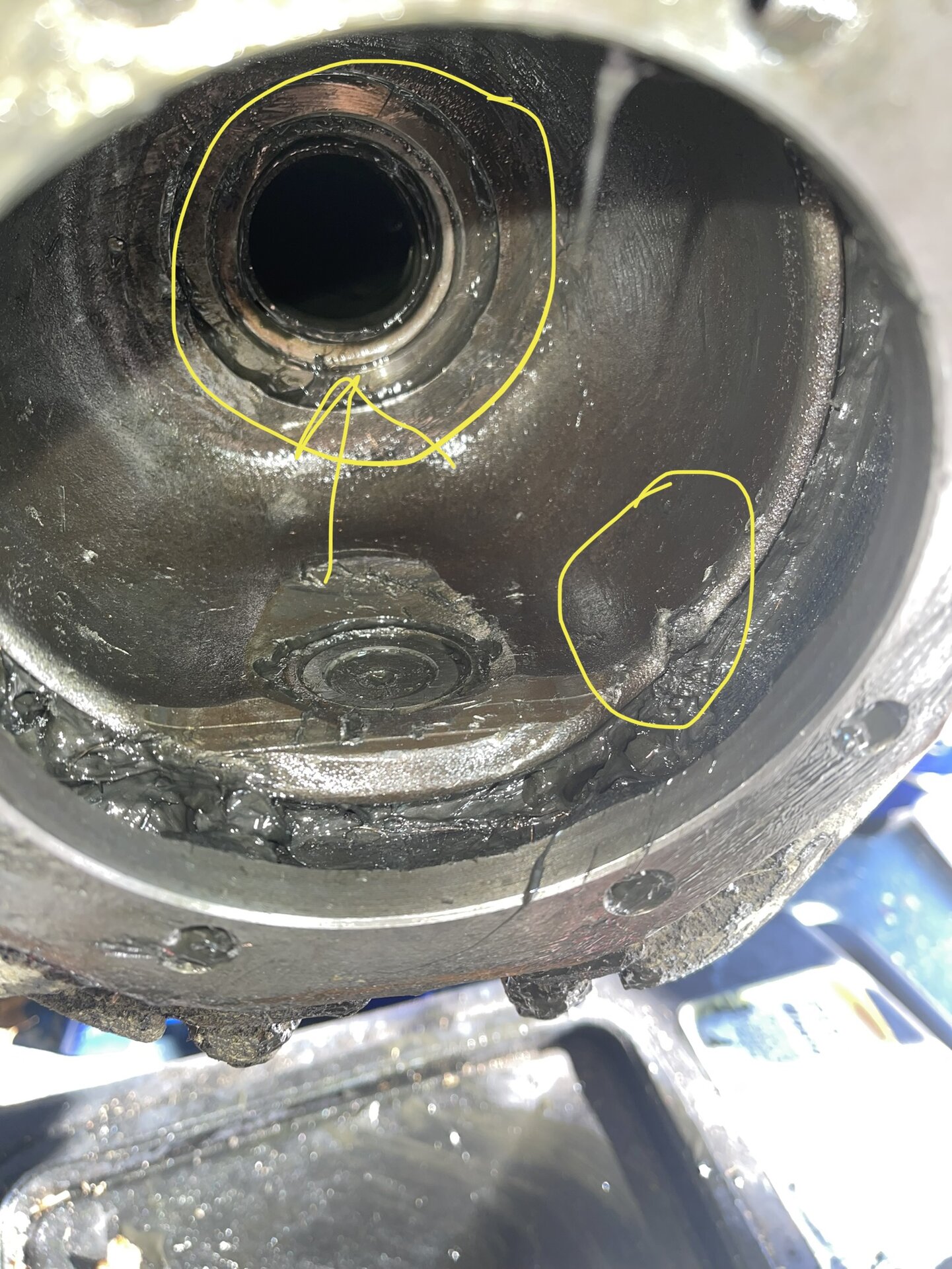

So I got it all pulled apart. As you guys predicted the birf was completely separated from the axle shaft and the ball bearings and chucks were wreaking havoc in the knuckle….. the inside of the knuckle has some scrapes and marring…. See pics.. also the inner axle seal was split apart and the inner half is actually pushed in the axle housing a bit towards the diff…. I can reach it with a curved pick so I assume I can just pry it out.

My thoughts on the inside of the knuckle are to smooth it out as best I can with a file and dremel. Is that a bad idea?

Also there was a bunch of what appeared to be copper wire pieces with a steel wool consistency…. You can see it in the pics. I’m assuming it’s the ABS speed sensor that got thrashed??

The axle shaft appears to be fine. All of the splines look normal.

My plan is to get it all cleaned up over the next couple weeks….

- Replace just the birfield

- install a knuckle rebuild kit (both sides)

- New rotors and pads

- Possibly new drive flanges

Should I replace the axle shaft for good measure? Or if it’s not broke don’t fix it….

Should I do left and right Birfs since I’m in there?

Truck has 314,000 miles on it.

I know I have to remove the end of the birf here. Just showing what was still attached..

My thoughts on the inside of the knuckle are to smooth it out as best I can with a file and dremel. Is that a bad idea?

Also there was a bunch of what appeared to be copper wire pieces with a steel wool consistency…. You can see it in the pics. I’m assuming it’s the ABS speed sensor that got thrashed??

The axle shaft appears to be fine. All of the splines look normal.

My plan is to get it all cleaned up over the next couple weeks….

- Replace just the birfield

- install a knuckle rebuild kit (both sides)

- New rotors and pads

- Possibly new drive flanges

Should I replace the axle shaft for good measure? Or if it’s not broke don’t fix it….

Should I do left and right Birfs since I’m in there?

Truck has 314,000 miles on it.

I know I have to remove the end of the birf here. Just showing what was still attached..

Last edited:

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)