Finished my 4x4Labs kit up yesterday and dropped it off at the sandblaster today. It was so much fun to build. Was basically my first welding project but I think I still did a pretty not-bad halfway decent job. I think the 4x4Labs rear is one of the best looking and most functional. Also considered Coastal but I don't like the side wings as much. Can't go wrong either way.

Cutting the rear crossmember took a lot more time than I had budgeted just because it's so close to the tailgate you have to get creative.

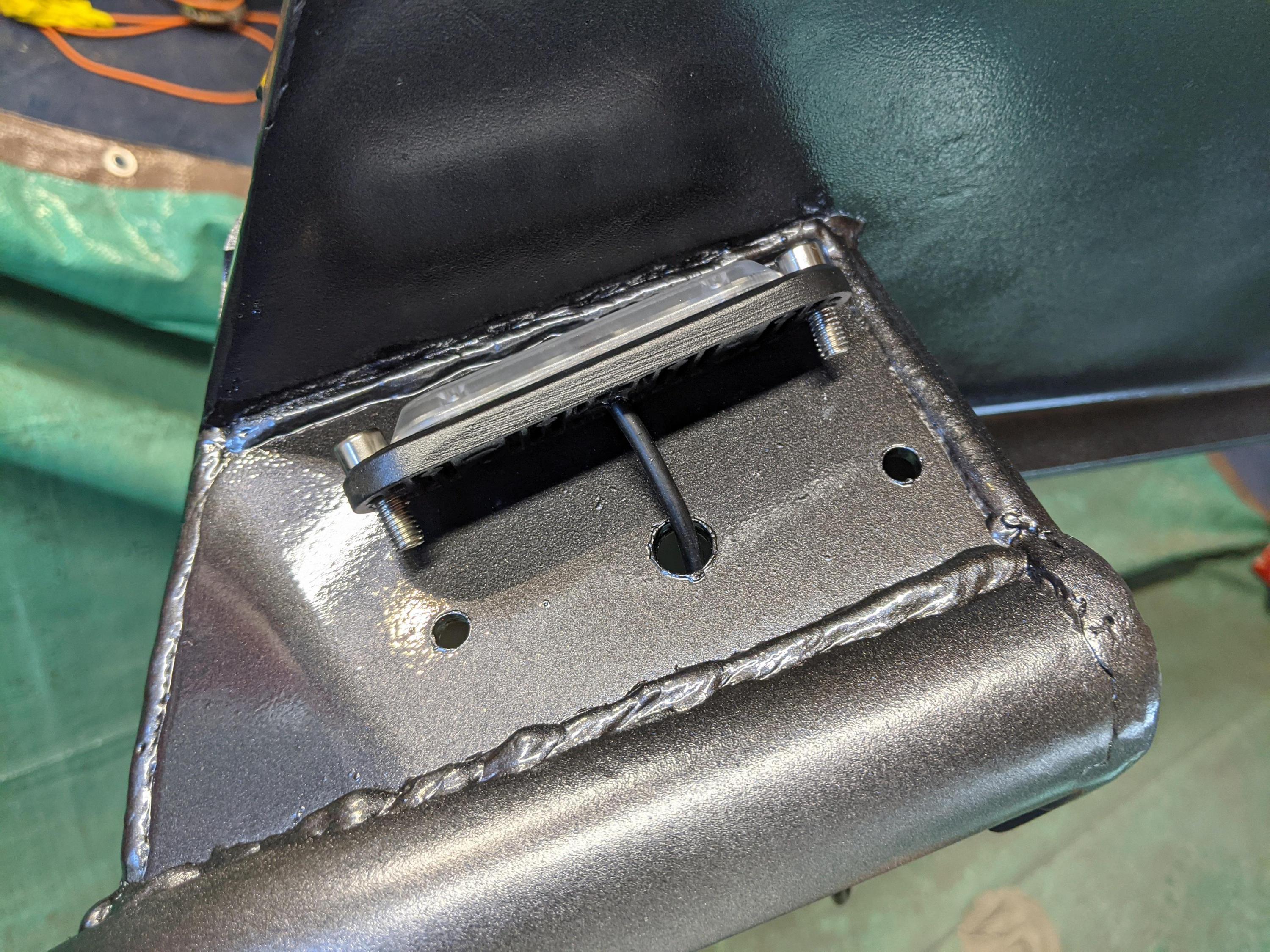

I didn't want swingouts unfortunately I guess the kit only comes one way so you get to fill in the holes yourself:

The Borla exhaust still fit on the stock hangars but hung way too far down. All it needed was a simple section taken out to move it up and back and tuck it way up tight. The second to rearmost rubber hangar I flipped upside down after bending it slightly, the rearmost hangar I cut from the stock crossmember and welded to the new 4x4Labs one.

Cut rectangular holes for reverse lights and also a hole for my trailer plug (not pictured)

So much clearance.

Will update when it's painted. I recently bought a Miller 211 and it worked perfectly for this job: Millermatic 211 MIG Welder With Advanced Auto-Set And Cart 951603 - - Amazon.com

Cutting the rear crossmember took a lot more time than I had budgeted just because it's so close to the tailgate you have to get creative.

I didn't want swingouts unfortunately I guess the kit only comes one way so you get to fill in the holes yourself:

The Borla exhaust still fit on the stock hangars but hung way too far down. All it needed was a simple section taken out to move it up and back and tuck it way up tight. The second to rearmost rubber hangar I flipped upside down after bending it slightly, the rearmost hangar I cut from the stock crossmember and welded to the new 4x4Labs one.

Cut rectangular holes for reverse lights and also a hole for my trailer plug (not pictured)

So much clearance.

Will update when it's painted. I recently bought a Miller 211 and it worked perfectly for this job: Millermatic 211 MIG Welder With Advanced Auto-Set And Cart 951603 - - Amazon.com

Last edited: