- Thread starter

- #21

On your site?My DENSO japan dealer sells this compressor NEW japan made

NOT reman .

clutch kit is available new also

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

On your site?My DENSO japan dealer sells this compressor NEW japan made

NOT reman .

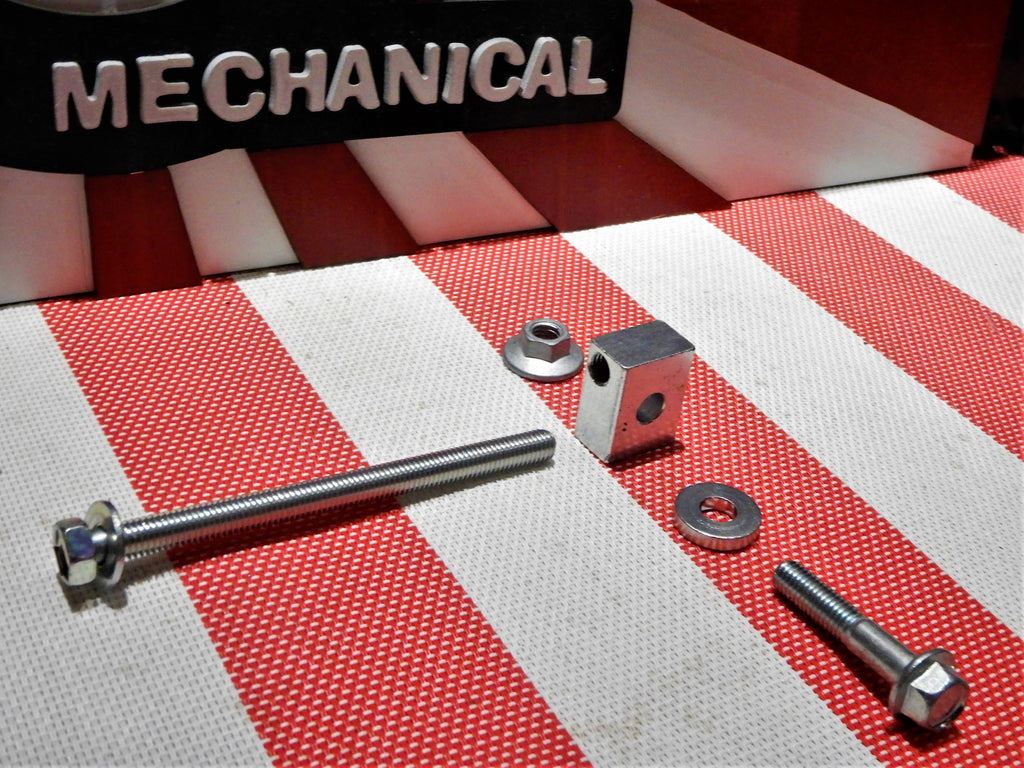

clutch kit is available new also

On your site?