- Joined

- Sep 26, 2003

- Threads

- 117

- Messages

- 11,199

- Location

- Lancaster, Ohio, USA

- Website

- www.tlcperformance.com

This is a thread to post up stories and pics of abused & blowed up Cruiser engines.

Hopefully we can learn things by examining these mortal remains, like how NOT to treat an engine for best performance.

I'll go first.

Subject is a 1987 2.5F engine. It was running at high speed on the interstate when it "lost power".

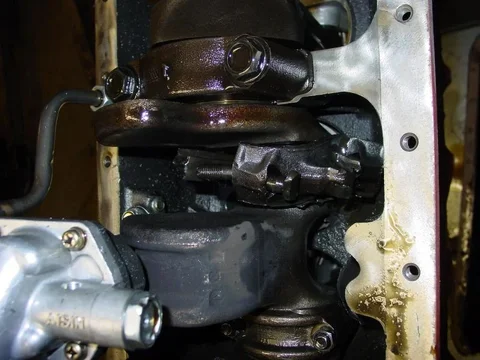

This is what it looked like on the outside. Hand grenade hole in the pan, not too bad. But note the bleeding bullet hole in the block, that's bad.

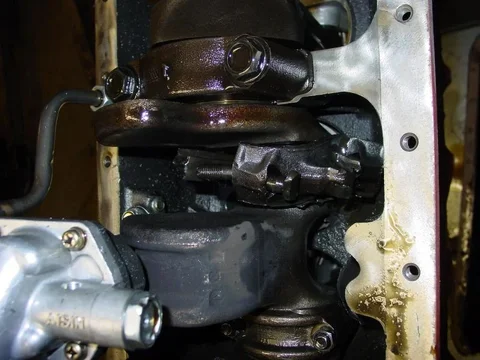

OK, the crank is junk. And that rod is... not a rod anymore.

And this rod is not too good either.

Hopefully we can learn things by examining these mortal remains, like how NOT to treat an engine for best performance.

I'll go first.

Subject is a 1987 2.5F engine. It was running at high speed on the interstate when it "lost power".

This is what it looked like on the outside. Hand grenade hole in the pan, not too bad. But note the bleeding bullet hole in the block, that's bad.

OK, the crank is junk. And that rod is... not a rod anymore.

And this rod is not too good either.

Last edited: