So I let the snowball get away on me and am remanufacturing my 22re engine.

The engine was my daily driver for years with 5.29's and 35's and I live in a mountainious city. The engine basically idled at 3k rpm and shifted regularly at 4500. Albiet some occasional hot ratttle clatter start up noise that I didnt figure out and #4 hole was lower compression, and all exh valves failed a leak down, it still ran strong, didnt smoke, and had good power.

A cold compression test showed holes 1-3 were all 165-170psi compression with #4 at around 145. A wet test on hole #4 came up to the 165ish mark. Leak down showed holes 1-3 leaking down at around 20% all notable through the exhaust. Around 35% on hole #4, notable through the exhaust. Couldnt tell whether or not any noise was coming from the bottom end. The oil pressure was 7psi HOT idle on 5w30 conventional oil. Tons of cold pressure and tons of cruising pressure.

Roughly speaking there was 150k miles on this engine. Its not factory to the truck with 256k miles on the dash, and word was it was a 88k mile engine that had the head gasket, cam, and timing chain done on it....the extra 62k miles is best guess.

I wasnt originally going to do much of anything to the 22re as I have motor swap plans in the forseeable future, but I did want to atleast semi-address the engine in the interim. What was going to be a quick valve service, timing chain kit, and head gasket got turned into a full remanufacture job pretty quick for no other reason than I'm in the right line of work to make it happen cheapish and the engine was already out of the hole.

I blew the complete engine assembly apart in record time, hot acid tanked the block and crank, washed it, decked it, and started punching it.

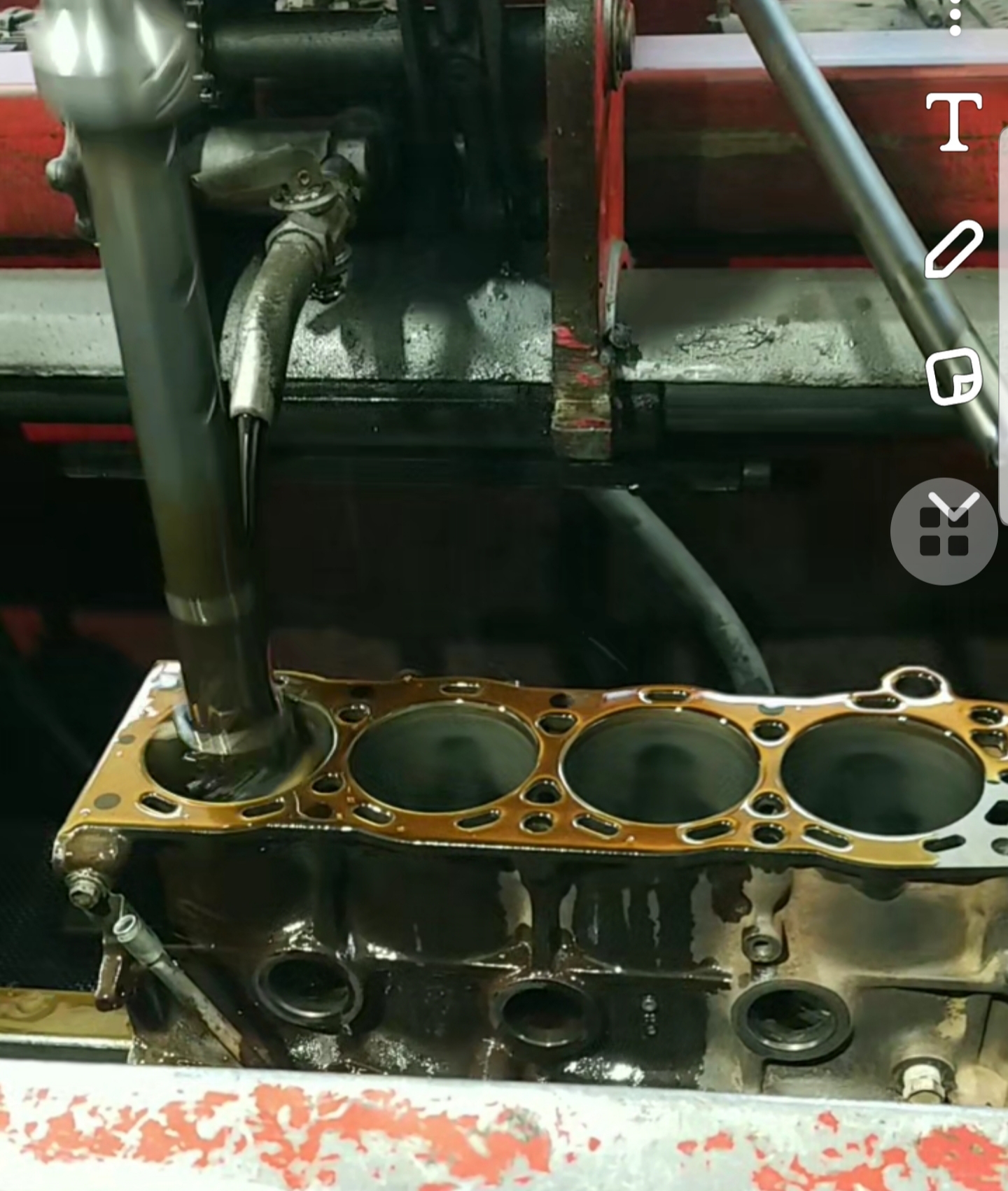

The deck took .012" to clean up. It was pretty straight and square around the #1 hole, didnt touch the middle much, and hit half of #4 hole. Lots of pitting and erosion around the water jackets. Didnt take a picture of the first pass, but thats it ready to come off the machine. I have no idea how this thing ever held a head gasket. Possibly lowish compression from a slightly lifted compression ring around #4 hole?

The timing chain guides were perfect. Best guess on the clatter is worn out tensioner.

All the intake valves vac'd like freshly machined valves and seats, and all 4 exhausts were roughly the same leakage rate.

All the bores were atleast .0015 taper and out of round. And .0015" larger than max spec. Cleaned up pretty quickly in the Sunnen Ck10.... no problem cleaning up for a .50mm piston. Aka roughly .020" over.

The bearings looked fairly good but just startimg to show some wear on the thrust sides. The crank measures standard and perfectly. The finish is just about as nice as it would be coming off the crank grinder, a polish will get it there. .0001" under max on the rod journals and .0003" under max on the main journals. Usually dont get this lucky when it comes to the crank. Toyota set this motor up pretty tight at the factory. It will go back in with standard bearings.

Thats all for now...

The engine was my daily driver for years with 5.29's and 35's and I live in a mountainious city. The engine basically idled at 3k rpm and shifted regularly at 4500. Albiet some occasional hot ratttle clatter start up noise that I didnt figure out and #4 hole was lower compression, and all exh valves failed a leak down, it still ran strong, didnt smoke, and had good power.

A cold compression test showed holes 1-3 were all 165-170psi compression with #4 at around 145. A wet test on hole #4 came up to the 165ish mark. Leak down showed holes 1-3 leaking down at around 20% all notable through the exhaust. Around 35% on hole #4, notable through the exhaust. Couldnt tell whether or not any noise was coming from the bottom end. The oil pressure was 7psi HOT idle on 5w30 conventional oil. Tons of cold pressure and tons of cruising pressure.

Roughly speaking there was 150k miles on this engine. Its not factory to the truck with 256k miles on the dash, and word was it was a 88k mile engine that had the head gasket, cam, and timing chain done on it....the extra 62k miles is best guess.

I wasnt originally going to do much of anything to the 22re as I have motor swap plans in the forseeable future, but I did want to atleast semi-address the engine in the interim. What was going to be a quick valve service, timing chain kit, and head gasket got turned into a full remanufacture job pretty quick for no other reason than I'm in the right line of work to make it happen cheapish and the engine was already out of the hole.

I blew the complete engine assembly apart in record time, hot acid tanked the block and crank, washed it, decked it, and started punching it.

The deck took .012" to clean up. It was pretty straight and square around the #1 hole, didnt touch the middle much, and hit half of #4 hole. Lots of pitting and erosion around the water jackets. Didnt take a picture of the first pass, but thats it ready to come off the machine. I have no idea how this thing ever held a head gasket. Possibly lowish compression from a slightly lifted compression ring around #4 hole?

The timing chain guides were perfect. Best guess on the clatter is worn out tensioner.

All the intake valves vac'd like freshly machined valves and seats, and all 4 exhausts were roughly the same leakage rate.

All the bores were atleast .0015 taper and out of round. And .0015" larger than max spec. Cleaned up pretty quickly in the Sunnen Ck10.... no problem cleaning up for a .50mm piston. Aka roughly .020" over.

The bearings looked fairly good but just startimg to show some wear on the thrust sides. The crank measures standard and perfectly. The finish is just about as nice as it would be coming off the crank grinder, a polish will get it there. .0001" under max on the rod journals and .0003" under max on the main journals. Usually dont get this lucky when it comes to the crank. Toyota set this motor up pretty tight at the factory. It will go back in with standard bearings.

Thats all for now...

Last edited: