So while crawling around in an internet rabbit hole researching something completely different today, I forget where I even started now... Oh yeah... I was the 'Pin 7 Center Diff Mod'... I stumbled onto the subject of Steering Arm Knuckle Studs.

Out of curiosity and once it cooled down outside here, I slid under the truck and found that I got about half a turn out of each of the four accessible stud nuts with my torque wrench set to about 75 ft-lbs, though some say 80+ lbs is appropriate. So they were loose... The problem now is accessing the two outer nuts closest to the brake dust shield. Anyone know a trick to accessing and torquing the nuts closest to the brake dust shield without tearing down the whole damn birf to remove said shield? Just pry and bend it out of the way with the wheel off?

Just pry and bend it out of the way with the wheel off?

From my reading this is an offroad field repair just waiting to happen and not a fun one... So I wonder how many of us have actually checked this from time to time? We've seen all manner of other carnage and malfunctions offroad, I wonder if a broken knuckle stud has impacted anyone yet...

Out of curiosity and once it cooled down outside here, I slid under the truck and found that I got about half a turn out of each of the four accessible stud nuts with my torque wrench set to about 75 ft-lbs, though some say 80+ lbs is appropriate. So they were loose... The problem now is accessing the two outer nuts closest to the brake dust shield. Anyone know a trick to accessing and torquing the nuts closest to the brake dust shield without tearing down the whole damn birf to remove said shield?

Just pry and bend it out of the way with the wheel off?

Just pry and bend it out of the way with the wheel off?From my reading this is an offroad field repair just waiting to happen and not a fun one... So I wonder how many of us have actually checked this from time to time? We've seen all manner of other carnage and malfunctions offroad, I wonder if a broken knuckle stud has impacted anyone yet...

- Broken Knuckle studs with >35s & How to prevent it - https://forum.ih8mud.com/threads/broken-knuckle-studs-with-35s-how-to-prevent-it.951678/

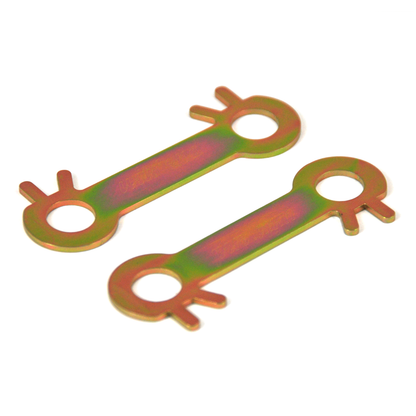

- How to Properly Install Toyota Steering Arm Knuckle Studs - https://www.roundforge.com/articles/how-install-maintain-toyota-steering-arm-knuckle-studs/