I'll start. Chat's dead and 40 mph wind gusts have me sitting in the truck, anyway.

Morphed project, one of which I typically would have no involvement in, but the GC is a very good account and didn't want to send looking.

Don't typically roof others structures, since inconsistencies in quality abound, and all metal roofing shows every minor error.

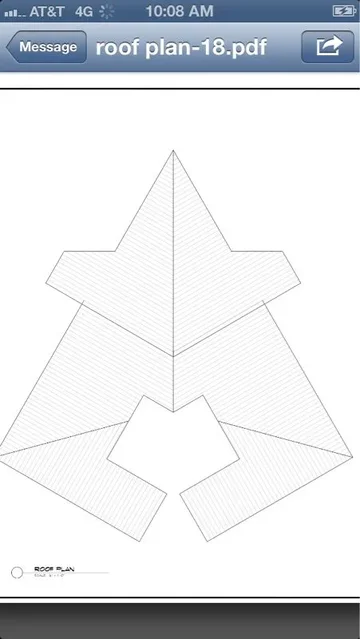

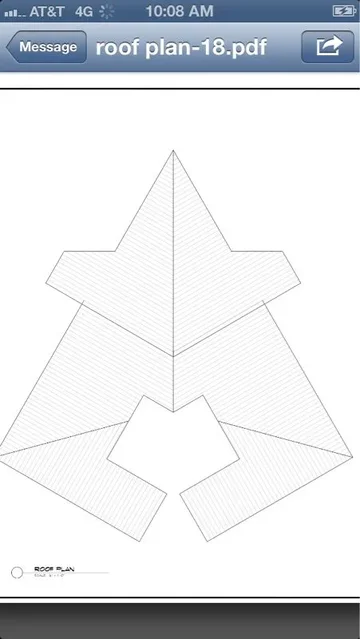

Began simple, but after architectural (Sorry, PAToyota) morphed into a cut up POS.

56' long panel runs, with only a handful of panels not necessitating cuts at both ridge and eave, panel lengths the longest I've handled.

9,100 sf of panel, but 8,918 sf of surface. Using 24Ga Architectural panel and still having issues with the 1/2"-3/4" variations in substrate in 27' runs.

Day two

It's hard to polish a turd.

No truer that in construction, where each trade is dependent on the previous to be accurate.....which never happens at this level. Why houses are, typically, not right.

Typically handle from foundation to drying in with steel, not this, which is the number one reason for suckage.

Jobsite is 1/8 mile from paved road and a heavy dew renders access impassable and not conducive for profitability ( which has been ever elusive the last few years, anyway ), plus daily inspections from the Corp of Engineers, each one with an ego that exceeds their level of experience, to which all you can do is I flare further, to minimize potential issues.

40mph gusts on top of a hill, to top it off.

Trying to move 56' long bundles of high dollar material is even challenging.