I will be doing a valve adjustment this weekend on my 85 BJ60.

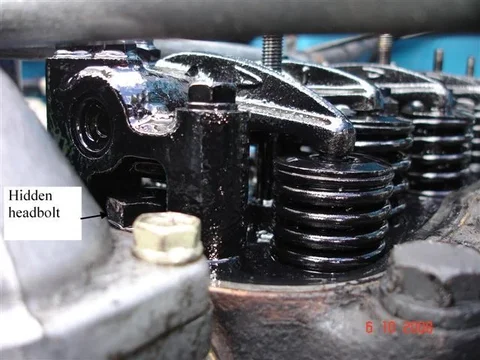

While I have the valve cover off, would it be worth while to re-torque the heads? Re-torquing diesel heads has always been common practice with me on anything from old 220 and 350 cummins motors to my IH idis in my Ford diesels. As the head bolts stretch over time and they almost ALWAYS take another half turn or so when I re-torque them. Prevents head gasket failures.

Should I do this with my 3B? if so, what is the torque sequence and specs?

While I have the valve cover off, would it be worth while to re-torque the heads? Re-torquing diesel heads has always been common practice with me on anything from old 220 and 350 cummins motors to my IH idis in my Ford diesels. As the head bolts stretch over time and they almost ALWAYS take another half turn or so when I re-torque them. Prevents head gasket failures.

Should I do this with my 3B? if so, what is the torque sequence and specs?