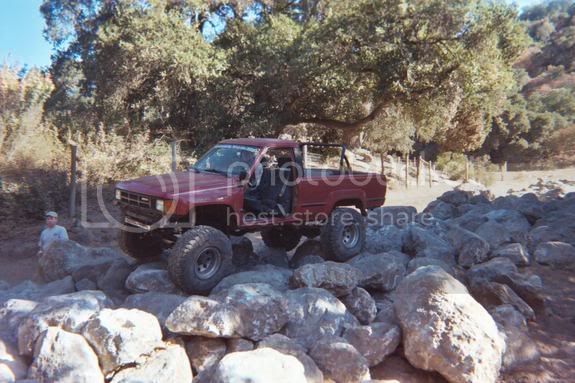

My 3rd 4wd Vehicle as of 2002. Not the best of them all, but by far the most capiable, and the most fun.

2002:

2003:

2004:

First real buildup including new springs, highsteer, 4.7 gears, sliders, new rear bumper.

2005:

Hammers at night- no pics, just broken parts

Big Bear:

2006:

Paid for new DD purchased in 05, and went wheeling in friends trucks.

2007:

Next up: Fixing the jankiness

2002:

2003:

2004:

First real buildup including new springs, highsteer, 4.7 gears, sliders, new rear bumper.

2005:

Hammers at night- no pics, just broken parts

Big Bear:

2006:

Paid for new DD purchased in 05, and went wheeling in friends trucks.

2007:

Next up: Fixing the jankiness