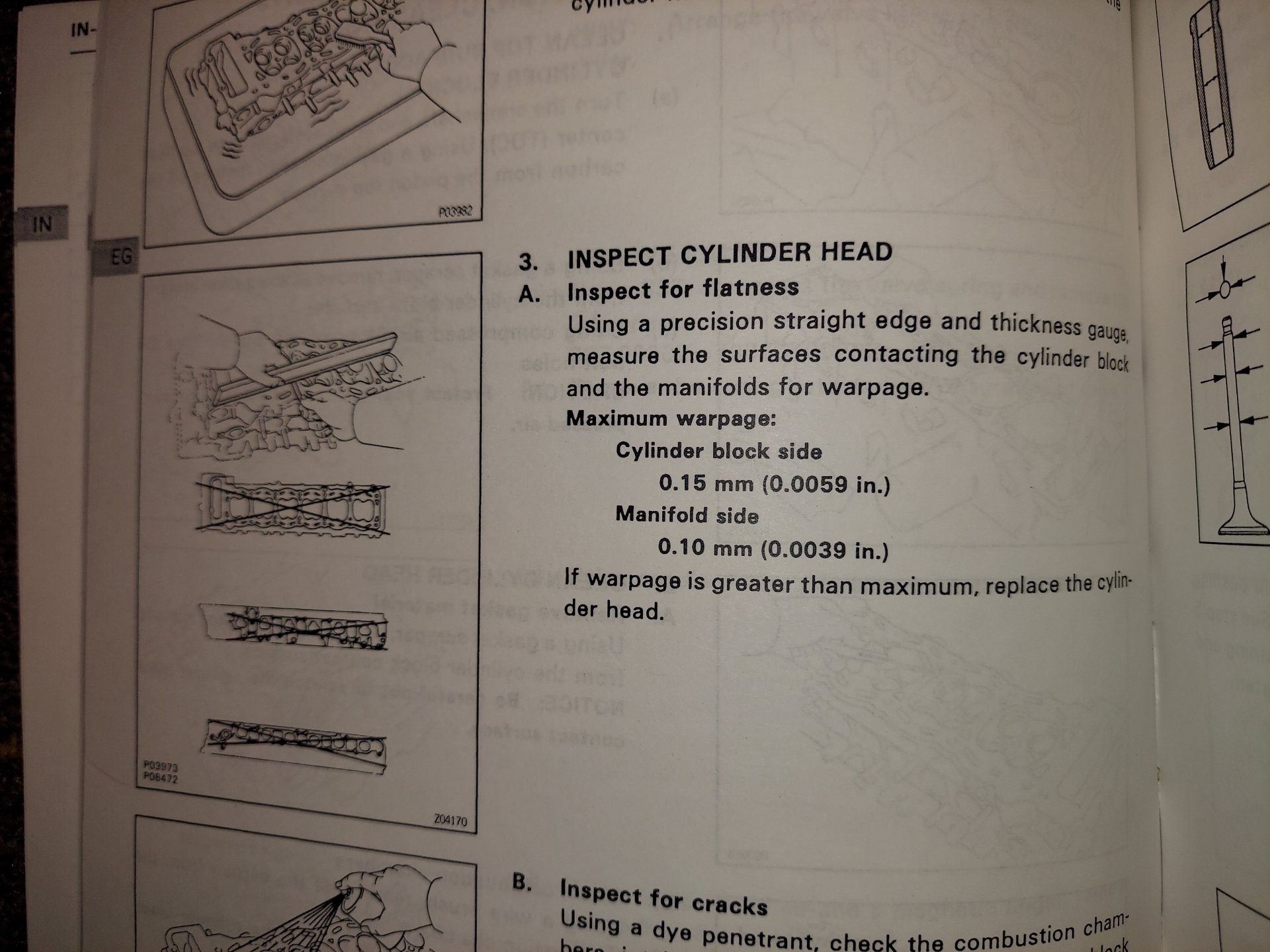

It is important to note that the factory makes no allowance for surfacing the head. It's either smooth and flat or you start over with a new head. This is the "correct" repair but rarely done. If it takes more than a couple of thousandths to clean up the surface you really should find an aftermarket head gasket such as Cometic where you can get a custom gasket that is thicker than stock to make up for the material removed from the head.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Head vs Rebuilt (and More)... (1 Viewer)

- Thread starter jaymar

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Could it affect timing if too much is taken off the head?It is important to note that the factory makes no allowance for surfacing the head. It's either smooth and flat or you start over with a new head. This is the "correct" repair but rarely done. If it takes more than a couple of thousandths to clean up the surface you really should find an aftermarket head gasket such as Cometic where you can get a custom gasket that is thicker than stock to make up for the material removed from the head.

View attachment 2949253

Sorry don't mean to derail the thread; I'm hoping these questions could help OP as well.

Could it affect timing if too much is taken off the head?

Sorry don't mean to derail the thread; I'm hoping these questions could help OP as well.

Yes, it can. The same applies to "decking" the cylinder block. That is not "allowed" either. Hypothetically if one were to take say 10 thou off the head and another 10 thou off the block, you would need a head gasket that is 20 thou thicker than stock to restore the geometry.

- Joined

- Sep 9, 2004

- Threads

- 200

- Messages

- 12,509

- Location

- Boise - Idaho

- Website

- www.snlandcruisers.com

I see the partsouq Toyota HG set is like $200, but they’re out. There is a ‘Teikin’ set for $56. That makes me a bit wary. Anyone used them?

ENGINE OVERHAUL GASKET KIT | Toyota LAND CRUISER VAN FZJ80G-GCPNK FJ80,FZJ80,HDJ81,HZJ81 | Parts Catalogs | PartSouq

If you are looking for ENGINE OVERHAUL GASKET KIT Parts for Toyota LAND CRUISER VAN FZJ80G-GCPNK FJ80,FZJ80,HDJ81,HZJ81 then we advise you to pay attention to the range of our spare parts catalog for Toyota!partsouq.com

You can use the coil pack 1FZFE head gasket.

Cheers

Yup, I was 0.22 warped...so I didnt want to deal with cam alignment and any other adjustments that could hinder the normalcy.

Malleus

Far west of Siegen

I'd like your opinion on what I was told by my machine shop: During the mid 90's, Toyota designed the heads so that there was very little material left on the lower face, to save weight and "officially" recommended that they head not be machined, to preserve the design EGR functionality (specifically, the volume of the combustion chamber, which was designed to be very close to what would have been required to meet then existing EPA rules).It is important to note that the factory makes no allowance for surfacing the head. It's either smooth and flat or you start over with a new head. This is the "correct" repair but rarely done. If it takes more than a couple of thousandths to clean up the surface you really should find an aftermarket head gasket such as Cometic where you can get a custom gasket that is thicker than stock to make up for the material removed from the head.

View attachment 2949253

Since, at least in NC, the 80 series are too old to be required to comply with emissions requirements, the shop owner, who's been in business since the early 90's, has made it a practice to recommend machining the lower face of the head. I know of no unfavorable results of his work.

Obviously, this may not help @jaymar since he's in the people's republic of California, which has declared war on ICE powered vehicles.

Malleus

Far west of Siegen

Not the intake specifically, but unplugging the harness, in preparation for removing the upper plenum. I pulled the head with the lower plenum and exhaust headers connected. I couldn't reach the rearmost nuts to remove them, with the head on the block, in the engine bay. Some have said they managed it, but they're better men than me.Valuable info, thanks for sharing. Did the knock sensors break when you took apart the intake?

I'd like your opinion on what I was told by my machine shop: During the mid 90's, Toyota designed the heads so that there was very little material left on the lower face, to save weight and "officially" recommended that they head not be machined, to preserve the design EGR functionality (specifically, the volume of the combustion chamber, which was designed to be very close to what would have been required to meet then existing EPA rules).

Since, at least in NC, the 80 series are too old to be required to comply with emissions requirements, the shop owner, who's been in business since the early 90's, has made it a practice to recommend machining the lower face of the head. I know of no unfavorable results of his work.

Obviously, this may not help @jaymar since he's in the people's republic of California, which has declared war on ICE powered vehicles.

That's the first I've heard of that story.

TurboDennis

SILVER Star

The

The main reason these heads should never be "decked" to correct for warp is because the top of the head (where the cam journals are) will remain warped after decking the bottom surface. This will lead to major issues with oil clearances for the cam journals. If your head has any warpage at all and you cant afford a new one, you'll be better off cleaning the gasket surface up the best you can by hand, and reinstalling the head as is. The torque from the head bolts will pull the head back into straightness (unless the warpage is extreme). If the bottom of the head was decked, the head bolts can no longer straighten it.

It is important to note that the factory makes no allowance for surfacing the head. It's either smooth and flat or you start over with a new head. This is the "correct" repair but rarely done. If it takes more than a couple of thousandths to clean up the surface you really should find an aftermarket head gasket such as Cometic where you can get a custom gasket that is thicker than stock to make up for the material removed from the head.

View attachment 2949253

The main reason these heads should never be "decked" to correct for warp is because the top of the head (where the cam journals are) will remain warped after decking the bottom surface. This will lead to major issues with oil clearances for the cam journals. If your head has any warpage at all and you cant afford a new one, you'll be better off cleaning the gasket surface up the best you can by hand, and reinstalling the head as is. The torque from the head bolts will pull the head back into straightness (unless the warpage is extreme). If the bottom of the head was decked, the head bolts can no longer straighten it.

Did it overheat at any point? If it didn't then the head could still be within spec to use and you might not have to have it shaved. It is possible the gasket just let go. When I did this job mine was getting combustion gasses in the coolant but it was never overheated. When I carried it to the machine shop to check tolerances they said it was still within spec and not worth doing anything to. I'd wait until you got the head off to determine what to do next.

Did it overheat at any point? If it didn't then the head could still be within spec...

My hg let go in my driveway... engine never overheated. Engine would run (lobishly) but never climbed in temp out of norm. Head was warped out of spec.

My thoughts are these heads run at such a high temp it is luck of draw once you unbolt it

- Thread starter

- #32

Great info! Would you happen to know the ballpark for a complete head?A new 1FZFE head (11101-69107) retails for close to $2000, smart shopper price $1500+/-. A new 1FZFE short block (11400-66041) retails for ~$4500, discounted price ~$3500+ depending on the discount, if any, that you can find.

All above refering to US sources (examples below):

Genuine Toyota Cylinder Head part# 11101-69107 for 1993-1997 Toyota Land Cruiser | Ourisman Toyota Parts| Official Online Store

Save Time and Money get your Genuine Toyota Cylinder Head (1110169107) For Your 1993-1997 Toyota Land Cruiser When You Shop With Ourisman Toyota Parts!toyotaparts.mcgeorgetoyota.com

11400-66041 - Block Assembly Short - Boch Toyota South

Block Assembly Short - 1140066041. Genuine Toyota® Parts & Accessories. Manufacturer Warranty. From the Dealership to your Door. Experts standing by.toyotaparts.bochtoyotasouth.com

COYS

SILVER Star

~$4KGreat info! Would you happen to know the ballpark for a complete head?

You can't buy a complete head. You have to build it from individual parts.Great info! Would you happen to know the ballpark for a complete head?

- Thread starter

- #35

Oh, right; I forgot, thanks! Okay: anyone have the cost of all parts handy?You can't buy a complete head. You have to build it from individual parts.

- Thread starter

- #36

Thanks! Is that with the bare head at ~$1500?~$4K

COYS

SILVER Star

COYS

SILVER Star

C'mon vet, search is still a friend. Get to work!Oh, right; I forgot, thanks! Okay: anyone have the cost of all parts handy?

1FZ-FE engine refresh parts list (OEM)

forum.ih8mud.com

forum.ih8mud.com

Last edited:

FMC80

SILVER Star

Have I ever told you that I love you?I'm finishing this job right now, and, although I haven't added up the receipts, and I'm doing all but the machine work myself, I think the total is around $1500. That includes (approximately) $450 for the gasket set, $500 for the machine work and the remainder in other parts. I did not need any new head parts, but I did need 6 new head bolts.

There are many threads on this job, but, FWIW:

1) I didn't pull the engine. I won't do that again. It saves no time and once out, you can access all the engine/transmission/transfer/engine bay/undercarriage to clean/update/etc, while you're waiting for the head to return. You're also taking a really big chance that your bores are cylindrical. If they're not, once the head's out, there is very little practical way to pull the engine.

2) Plan on breaking some, or all, of the sensors, connectors, or both, on the intake side of the head/engine. You may not, but I lost 50% of them due to age-related material failure. Everything I broke is still available. Ballenger has the OEM Sumitomo connectors, with the terminals, which you have to figure out and order separately from Toyota. Unless you really want to rewire the connector housings (I am, but that's just me), I'd recommend the pigtails - much easier to install.

3) I took the time to replace the brushes in the alternator and starter (I actually rebuilt both). Full rebuild kits are available from Alternator and Starter Parts Wholesale (I highly recommend them). Toyota only lists limited parts for both. You can rebuild them yourself, or just replace the brushes, for a fraction of the cost of replacement. Now is the time, while they're out, or accessible.

I would also replace the JIS cross head screws (all 4) on the starter housing with socket head cap screws. You'll understand why once you try to remove them. They are glued in, and, although the installation torque is low, the heads are ridiculously soft and will strip out. I've repaired several, and stripped the screws on every one. They will come out with an EZ-Out. Replacements are not available from Toyota, since they are not considered a wear item.

4) Suspension components, at least shocks and swaybar bushings, are easiest to access while the head/engine is out. If you replace the shocks, plan to replace the swaybar bushings, because you can't access them unless the shocks are out.

5) I failed to do this, but the engine shop has the facilities to thoroughly clean the intakes and throttle body. If you decide to do it yourself, buy some Carbon-Off to remove the crud from inside all three (Brakleen will remove it, but it's ridiculously expensive for the whole set). I spent two weeks trying to clean mine with at least a dozen chemicals and abrasives; none worked on the interiors to completely remove the burned in carbon. My bead blast media wouldn't even remove some of the baked in stuff. It did polish the exterior really well, though.

I would not recommend assembling the intakes and throttle body unless they are as clean as the interior of the head. This is the only time you can safely get all that crud out and if Toyota wanted it in there, they'd have shipped the new engines with it lining the intakes.

6) I replaced every coolant hose and vacuum line. They all needed to be replaced. Many recommend Napa-type vacuum lines, but they are not metric sized and do not fit closely on the vacuum nipples. Toyota still sells vacuum lines, 90999-92008 (I bought 2-m). I also replaced my heater valve, because it was leaking; check yours before you throw money at it. This is one of the few engine bay items that can be replaced with everything else installed.

7) I blasted my exhaust headers and coated them with VHT primer/paint/clearcoat. We'll see how long it lasts. My next set will be Cerakote finished. I also applied VHT clearcoat to all the steel and aluminum parts I cleaned. Just to make them easier to clean later, and because I had it left over.

8) Now is the time to electrically check all the intake/throttle body-mounted sensors. If you don't know how to use the DMM, you will by the time you're done (Toyota training is in the Resources section).

9) Finally, don't forget new plugs and oil/oil filter. I replaced the OEM fuel filter a couple of years ago, so it's going back in. If you haven't replaced yours, now is the time.

Again, many other threads here on oil cooler, oil pump, power steering pump, cooling lines, removal of a) EGR, b) PHH, etc. I didn't touch any of that, because I didn't have the need. You may.

HTH

Malleus

Far west of Siegen

Nope. But you did just earn a spot on my Christmas card list.Have I ever told you that I love you?

Similar threads

- Replies

- 2

- Views

- 575

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)