Cut between the bracket and bushing. Part frozen in bushing will stay in. Press bushing out , press new in.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lower control arm options

- Thread starter Brett19648

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Nice new deck!Cut between the bracket and bushing. Part frozen in bushing will stay in. Press bushing out , press new in.

View attachment 1479917

Good lord I need to pay more attention - thank you...its an ongoing projectNice new deck!

Cut between the bracket and bushing. Part frozen in bushing will stay in. Press bushing out , press new in.

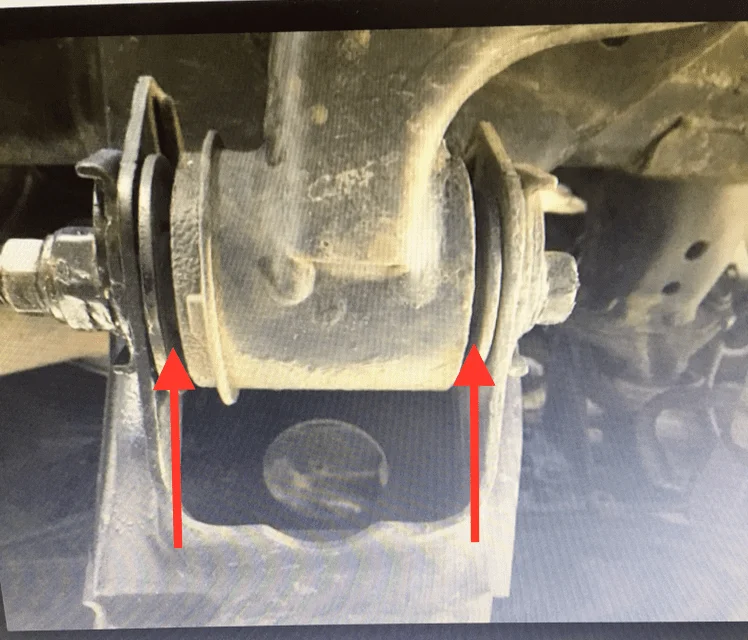

Where the red arrows are pointing in this pic is where I should cut then?

- Thread starter

- #26

Yes that's the spot. Would have helped if I had mentioned where specifically to cut.

Yes that's the spot. Would have helped if I had mentioned where specifically to cut.

You did. I just wanted to make sure I was following you. I'd hate to cut in the wrong place.

On those SPC cam bolts should I apply any anti-seize or are they good to go as is?

- Thread starter

- #28

Supposedly they're good to go, but I put anti seize all over them anyway. Figured it couldn't hurt.

Can somebody provide the links for the SPC cam bolts and the SPC extractor tool? The link earlier in this thread is for Tundra (not sure if it's the same). My shop as well says mine is seized, but i want to have them look again and tell me if they think the SPC cam bolts along with the extractor tool would be an option

TexAZ

NEW???? It's BETTER than new!!!

The lower control arm bushings and cam bolts are the same between the Tundra and 200.

here is a link for the cam bolt removal tool.

www.summitracing.com

www.summitracing.com

here is a link for the cam bolt removal tool.

SPC Performance 40915 SPC Performance Cam Extractor Presses | Summit Racing

Free Shipping - SPC Performance Cam Extractor Presses with qualifying orders of $109. Shop Bushing and Bearing Installation and Removal Tools at Summit Racing.

Thanks @TexAZ much appreciated. It was about a year ago i had it at CBT when i got my lift installed. At that point they told me my LCA's were seized, and that they couldn't adjust at all when they got to doing the alignment. Pardon my ignorance, but which part on the LCA's is the part they adjust for the alignment? Does it sound like the Cam Bolt Kit and tool would fix the issue for me?The lower control arm bushings and cam bolts are the same between the Tundra and 200.

here is a link for the cam bolt removal tool.

SPC Performance 40915 SPC Performance Cam Extractor Presses | Summit Racing

Free Shipping - SPC Performance Cam Extractor Presses with qualifying orders of $109. Shop Bushing and Bearing Installation and Removal Tools at Summit Racing.www.summitracing.com

TexAZ

NEW???? It's BETTER than new!!!

the green arrows point to the adjusting cam bolts. as the bolt/cam is turned it pushes the lower control arm further from the center of the hole. the SPC part, replaces the bolts with new hardware and a plastic sleeve to keep the bolt from rusting to the frame.

the tool is just a modified clamp used to push the old bolts out. i would start applying PB blaster, or your favorite rust breaker/lube every couple days to start soaking the hardware a hopefully breaking up the rust. SPC has a disclaimer on the product description that says the tool may not work if bolts are too rusted in place....take that for what you will. even they know its not a guaranteed solution.

be prepared to cut out the bolts.

check with camelback and make sure they have a set of arms in stock before dissasembly. several members have had issues where the bolts must be cut out. in case everything goes sideways, good to know there are replcement parts available.

if not the arms, at least new bolts and bushings.

the tool is just a modified clamp used to push the old bolts out. i would start applying PB blaster, or your favorite rust breaker/lube every couple days to start soaking the hardware a hopefully breaking up the rust. SPC has a disclaimer on the product description that says the tool may not work if bolts are too rusted in place....take that for what you will. even they know its not a guaranteed solution.

be prepared to cut out the bolts.

check with camelback and make sure they have a set of arms in stock before dissasembly. several members have had issues where the bolts must be cut out. in case everything goes sideways, good to know there are replcement parts available.

if not the arms, at least new bolts and bushings.

Thanks for all the detailed info. The advice I got at the time from Camelback was that since the bushings were still good, I’d be better just leaving the lowers as-is and changing out the uppers to get the adjustment. The alignment was real close, just outta range. They were worried in cutting they’d mess up the arms and I’d have to replace, which is a lotta money for Factory lowers and not a lotta fun in getting them. I’ve just been ignoring it the past year, it just weighs on me knowing I gotta deal with it eventually. Next time I take the truck in I’ll show them my idea and have the new tech see what he thinksthe green arrows point to the adjusting cam bolts. as the bolt/cam is turned it pushes the lower control arm further from the center of the hole. the SPC part, replaces the bolts with new hardware and a plastic sleeve to keep the bolt from rusting to the frame.

the tool is just a modified clamp used to push the old bolts out. i would start applying PB blaster, or your favorite rust breaker/lube every couple days to start soaking the hardware a hopefully breaking up the rust. SPC has a disclaimer on the product description that says the tool may not work if bolts are too rusted in place....take that for what you will. even they know its not a guaranteed solution.

be prepared to cut out the bolts.

check with camelback and make sure they have a set of arms in stock before dissasembly. several members have had issues where the bolts must be cut out. in case everything goes sideways, good to know there are replcement parts available.

if not the arms, at least new bolts and bushings.

I have a seized cam bolt on my LCA as well. Did you end up having to cut yours off? If so, how did you go about do it?

My similar story:

I discovered this LCA's horror after lifting my 08 LC200. These things were like welded on solidly. The alignment stayed them same even after Tough Dog susp lift. We were unable to removed the LCA's in order to replace the bushings. After some attempts by mechanic, we decided to cut through them and went with new OEM LCA's.

2 new OEM LCA's cost me $620 (got a wholesale deal).

But even destroying/cutting through the LCA's was not easy.

Rusted LCA's and KDSS bolts forced me to learn a lot about this LC's underbelly (not by choice). But my OCD side is much happier now that I've gotten much of the ugly rusty stuff from under the truck. Still got some more grinding and painting to do. But I guess we will never finish messing around with our LC's.

Good luck with your choices.

My similar story:

I discovered this LCA's horror after lifting my 08 LC200. These things were like welded on solidly. The alignment stayed them same even after Tough Dog susp lift. We were unable to removed the LCA's in order to replace the bushings. After some attempts by mechanic, we decided to cut through them and went with new OEM LCA's.

2 new OEM LCA's cost me $620 (got a wholesale deal).

But even destroying/cutting through the LCA's was not easy.

Where did your truck come from? The lowers you took off appear to be in great shape with regard to corrosion/rust yet clearly they still gave you a fit. I think there's a lesson to be learned for everyone who thinks buying a largely rust free truck prevents these types of events, the LCAs are a major PITA regardless of where the vehicle has lived.

If you're fine with it as-is for now you could wait for the next person to do a Tundra swap and see if you can grab their LC lowers. I replaced a 13s LCAs in March of 16 and they were fine, some rust on the cam bolt sleeve but they popped right out no problem. SoCal vehicle.

Where did your truck come from? The lowers you took off appear to be in great shape with regard to corrosion/rust yet clearly they still gave you a fit. I think there's a lesson to be learned for everyone who thinks buying a largely rust free truck prevents these types of events, the LCAs are a major PITA regardless of where the vehicle has lived.

I always prefer my trucks to be from CA and the Southwest US. However, during my search for the LC200, nothing in my search range (08-11) came up that was close to me to be able to test drive beside this 08 LC200 from Thousand Oaks Toyota. It had been a So Cal truck for about 3 years after a few years in New England prior to that. I dislike unclean truck underbellies with a passion.

Similar thing happened to me in my search for my FJ Cruiser before that. The upside is I've since gotten better at grinding, sanding, painting, replacing rusted nuts and bolts, etc. ...

I know there is a bunch of detailed info out there, but if you were to sum in up what are the pros and cons of doing the Tundra swap. Just wondering what all is involved and if that’s be a better option for meIf you're fine with it as-is for now you could wait for the next person to do a Tundra swap and see if you can grab their LC lowers. I replaced a 13s LCAs in March of 16 and they were fine, some rust on the cam bolt sleeve but they popped right out no problem. SoCal vehicle.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)