Hello,

I've got a Trail-Tailor KCT I'm trying to use. A few questions.

1) Instructions suggest it is necessary to remove the birf oil seal. However it seems the 'plug' of the tool (which marks the rod) fits inside the seal perfectly. Remove or don't? (seal only has 20 miles on it).

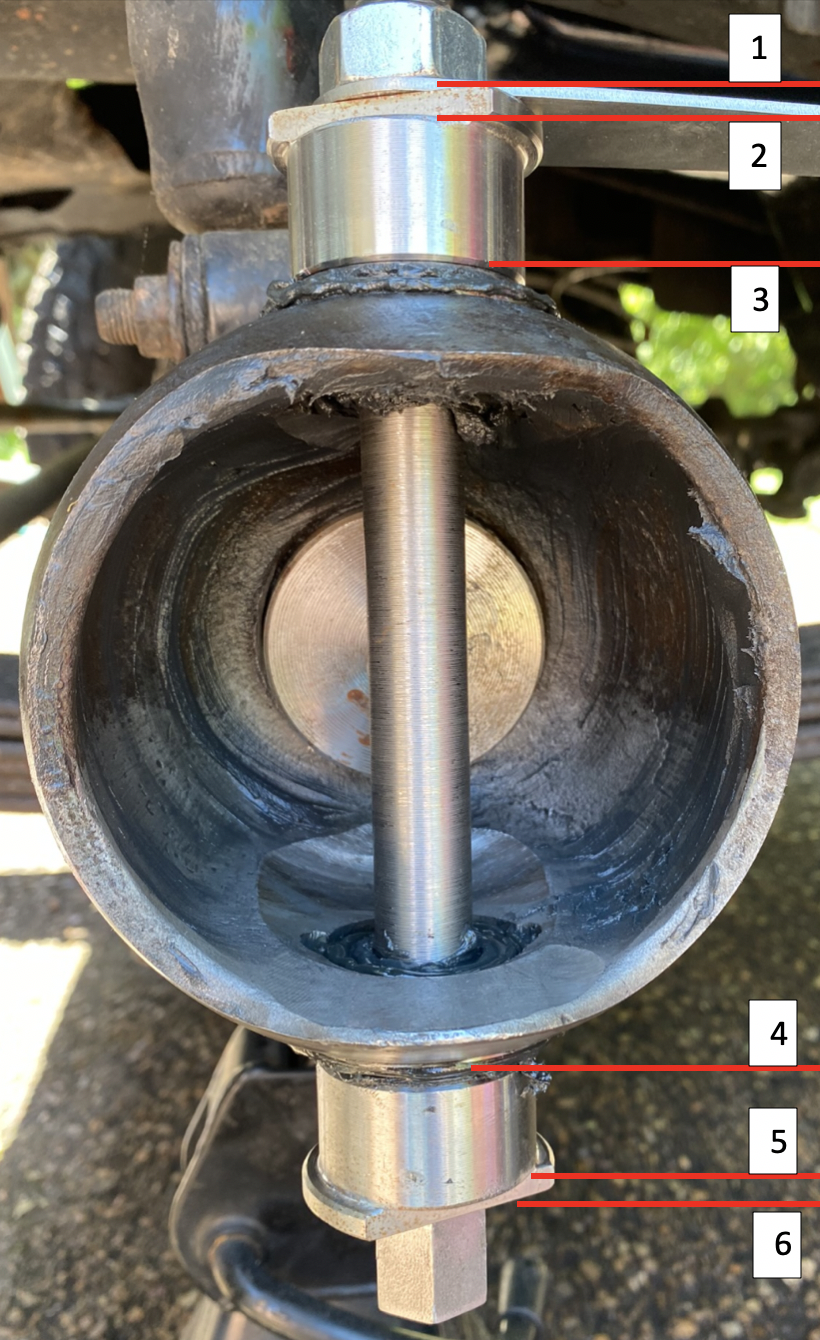

2) Measurement A (photo from instructions below). This illustration is not clear (calipers and spread of "A" lines are not measuring the same thing). The only YouTube video I have seen does not clearly show (and frustratingly obscures view with his forearm). Any insight as to what points in the photo below are to be used for measurement of A? Looks like it could either be 1-6 or 2-5. Any help?

.

.

I've got a Trail-Tailor KCT I'm trying to use. A few questions.

1) Instructions suggest it is necessary to remove the birf oil seal. However it seems the 'plug' of the tool (which marks the rod) fits inside the seal perfectly. Remove or don't? (seal only has 20 miles on it).

2) Measurement A (photo from instructions below). This illustration is not clear (calipers and spread of "A" lines are not measuring the same thing). The only YouTube video I have seen does not clearly show (and frustratingly obscures view with his forearm). Any insight as to what points in the photo below are to be used for measurement of A? Looks like it could either be 1-6 or 2-5. Any help?