I am in the midst of timing belt and water pump change on our LX and thought I'd share my progress and get your input. Its my first time changing a timing belt and I am enjoying digging in and getting to know the truck.

2001 LX 470 104k miles. First TB change. First Water pump. AZ Mall cruiser - until me.

Disassembly has been pretty straight forward so far, but I am not done yet. I am going slow. I am also putting as many of the bolts and nuts back in their original locations as I can, rather than bag them. Works better for me than bagging and trying to remember where everything goes.

- Drained coolant with the drain valve on the bottom of the radiator.

- Removed air box and duct, no issues there. Next I went to the radiator hoses (upper and lower).

- Removed upper and lower radiator hoses. On the outlet side (DS or Toyota LH) I found some pitting and corrosion where the radiator hose clamps to the outlet port. I think this is what happens when you don't change your engine coolant every 30K like Toyota recommends. Comments?

The hoses were Napa with screw clamps, not Toyota. Also the radiator has been replaced with non-OEM at 90k miles. I am going to keep it for now. On a recent trip to MX, Ultragauge showed me a some periods where the coolant temp got to 199F when the car got up to 75+ mph. This prompted me to do the TB and Water pump now rather than later. Generally I never see the temp much above 190F. I noticed some splatter of coolant on the air intake manifold - probably from this coolant outlet interface. I don't plan to replace this outlet tube at this point unless it leaks when I reassemble.

- Heater T's next - since the engine was drained. Sure enough the "hot side" or outlet T (I assume so anyway) broke and crumbled during removal. This is an 01 with 104k miles on it. AZ vehicle. In removing the broken side (on the engine side) I was very worried about fragments falling back into the engine. I don't want those little pieces percolating through the system. I thought about it over night and decided to to use my shop vac to suck as much coolant as I could out through that port. I got a lot of red coolant out and I hope any of those fragments out with it. Replaced with a new T and put the clamps with the ears facing up for next time.

- Fan shroud was just a pain. Broke one of the ears for the DS shroud clamp bolt (like scottm). Will use JB Weld and a washer to fix it once the shroud is back in. These AZ trucks don't have the rust, but they get brittle too with the dry heat. Several of the wire and hose plastic clamps are pretty delicate after 13 years.

- Fan and Fan clutch. I discovered when removing the radiator cooling fan assembly that one of the nuts was a 13 mm non-OEM item. So I added the correct nut to my parts list. Always disconcerting to find non-OEM parts.

- Thermostat housing and inlet pipe assembly. Two bolts and gently pried it out of its O-ring. Turned it over and discovered more corrosion. This is concerning.

Its not terrible, but I worry about additional corrosion in areas where I can't see, that may weaken the manifold and result in a blow out type leak one day. I am contemplating changing the cross over tubes when I do the starter - in about 50K miles I expect. I am hopeful that replacing with new coolant and changing it regularly will avoid further corrosion. Also I think the corrosion only happens when there's air/steam, so it should only happen at the high points/air pockets in the system?

Its not terrible, but I worry about additional corrosion in areas where I can't see, that may weaken the manifold and result in a blow out type leak one day. I am contemplating changing the cross over tubes when I do the starter - in about 50K miles I expect. I am hopeful that replacing with new coolant and changing it regularly will avoid further corrosion. Also I think the corrosion only happens when there's air/steam, so it should only happen at the high points/air pockets in the system?

What do you think?

-Timing belt covers were OK. The PS side was easy and the DS a little harder. I have a hard time getting those electrical connectors to let go sometimes. Watch out for the inside clip on the lower left edge (facing the engine) on the DS cover. The DS one will take some wiggling to get out and back in, past the wires etc. Had to remove the oil filter cooler line for this one - no big deal. The middle cover was ok too.

- Fan bracket. Hardest part was the two nuts down by the AC compressor. The Land Cruiser Service Manual I have (hoping its same as the LX - or close enough) says that I should remove the AC compressor - but I didn't. I removed the two long bolts clamping the fan bracket to the AC comp bracket and followed spresso's advice to just bend the electrical connector bracket out of they way. Much easier. Thanks for that!

- Next up will be moving the Alternator out of the way.

I welcome your thoughts and input. Learning a lot about the truck and whats in there - which is the whole point.

2001 LX 470 104k miles. First TB change. First Water pump. AZ Mall cruiser - until me.

Disassembly has been pretty straight forward so far, but I am not done yet. I am going slow. I am also putting as many of the bolts and nuts back in their original locations as I can, rather than bag them. Works better for me than bagging and trying to remember where everything goes.

- Drained coolant with the drain valve on the bottom of the radiator.

- Removed air box and duct, no issues there. Next I went to the radiator hoses (upper and lower).

- Removed upper and lower radiator hoses. On the outlet side (DS or Toyota LH) I found some pitting and corrosion where the radiator hose clamps to the outlet port. I think this is what happens when you don't change your engine coolant every 30K like Toyota recommends. Comments?

The hoses were Napa with screw clamps, not Toyota. Also the radiator has been replaced with non-OEM at 90k miles. I am going to keep it for now. On a recent trip to MX, Ultragauge showed me a some periods where the coolant temp got to 199F when the car got up to 75+ mph. This prompted me to do the TB and Water pump now rather than later. Generally I never see the temp much above 190F. I noticed some splatter of coolant on the air intake manifold - probably from this coolant outlet interface. I don't plan to replace this outlet tube at this point unless it leaks when I reassemble.

- Heater T's next - since the engine was drained. Sure enough the "hot side" or outlet T (I assume so anyway) broke and crumbled during removal. This is an 01 with 104k miles on it. AZ vehicle. In removing the broken side (on the engine side) I was very worried about fragments falling back into the engine. I don't want those little pieces percolating through the system. I thought about it over night and decided to to use my shop vac to suck as much coolant as I could out through that port. I got a lot of red coolant out and I hope any of those fragments out with it. Replaced with a new T and put the clamps with the ears facing up for next time.

- Fan shroud was just a pain. Broke one of the ears for the DS shroud clamp bolt (like scottm). Will use JB Weld and a washer to fix it once the shroud is back in. These AZ trucks don't have the rust, but they get brittle too with the dry heat. Several of the wire and hose plastic clamps are pretty delicate after 13 years.

- Fan and Fan clutch. I discovered when removing the radiator cooling fan assembly that one of the nuts was a 13 mm non-OEM item. So I added the correct nut to my parts list. Always disconcerting to find non-OEM parts.

- Thermostat housing and inlet pipe assembly. Two bolts and gently pried it out of its O-ring. Turned it over and discovered more corrosion. This is concerning.

What do you think?

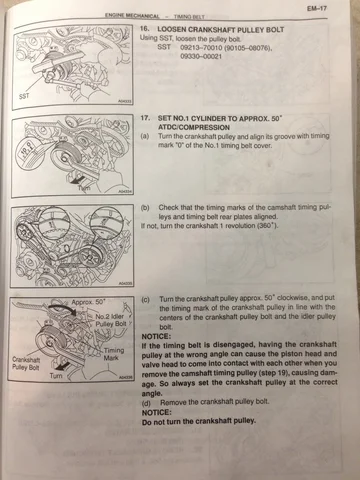

-Timing belt covers were OK. The PS side was easy and the DS a little harder. I have a hard time getting those electrical connectors to let go sometimes. Watch out for the inside clip on the lower left edge (facing the engine) on the DS cover. The DS one will take some wiggling to get out and back in, past the wires etc. Had to remove the oil filter cooler line for this one - no big deal. The middle cover was ok too.

- Fan bracket. Hardest part was the two nuts down by the AC compressor. The Land Cruiser Service Manual I have (hoping its same as the LX - or close enough) says that I should remove the AC compressor - but I didn't. I removed the two long bolts clamping the fan bracket to the AC comp bracket and followed spresso's advice to just bend the electrical connector bracket out of they way. Much easier. Thanks for that!

- Next up will be moving the Alternator out of the way.

I welcome your thoughts and input. Learning a lot about the truck and whats in there - which is the whole point.

's Dodge/Cummins front and rear diff covers as that's the way it comes from the factory, i.e., no gaskets. The stuff is bulletproof. Let it set for an hour or 3 before adding coolant.

's Dodge/Cummins front and rear diff covers as that's the way it comes from the factory, i.e., no gaskets. The stuff is bulletproof. Let it set for an hour or 3 before adding coolant.