Looking to install 10K winch in a hidden winch mount behind OEM bumper.

Anybody willing to share their build pictures and notes.

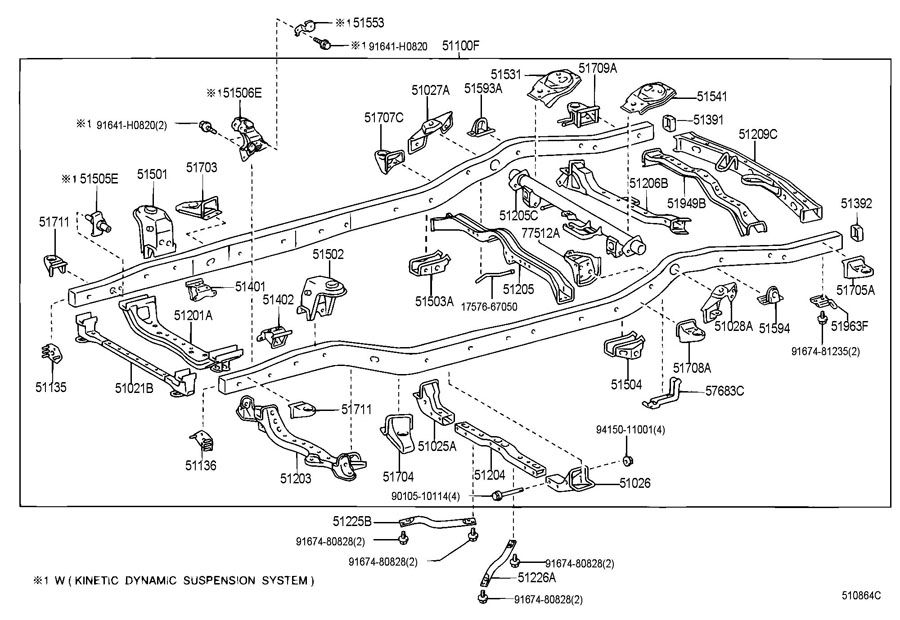

I seen BudBuild hidden winch mount and it seems easy enough to duplicate. SSO hidden winch mount seems to be the obvious easy choice. I already have WARN universal winch plate from previous project, so its no cost to me.

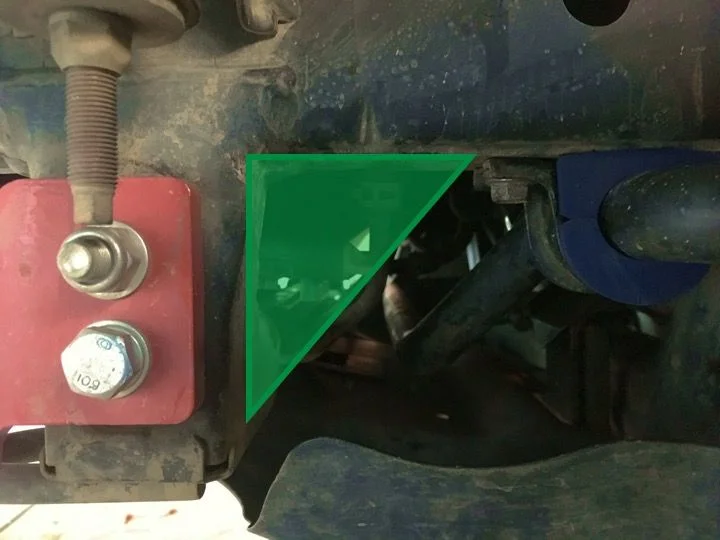

My initial measurement indicate some potential issue with the winch bolt. The 10x4.5 winch bolt pattern might fall right above the OEM bumper beam.

My initial plan:

Anybody willing to share their build pictures and notes.

I seen BudBuild hidden winch mount and it seems easy enough to duplicate. SSO hidden winch mount seems to be the obvious easy choice. I already have WARN universal winch plate from previous project, so its no cost to me.

My initial measurement indicate some potential issue with the winch bolt. The 10x4.5 winch bolt pattern might fall right above the OEM bumper beam.

My initial plan:

- Chop the front side of the channel mount to be able to move the failed support right behind the bumper.

- Chop winch channel back side a bit to be able to clear the power steering / AC lines

- Weld the plate to the OEM bumper beam.

- Gusset the channel to the OEM bumper beam

- Maybe add some metal strap to some other bolt holes on the FRAME.

- Use Allen head bolt to mount the winch to the channel.