All good I have to report back.

I did the whole TTY am MLS story and over 100 odd kays of test driving, all seems good.

Thank you all, but especially to Greg and Tom for the help.

Now, one more just before signing this thread off.

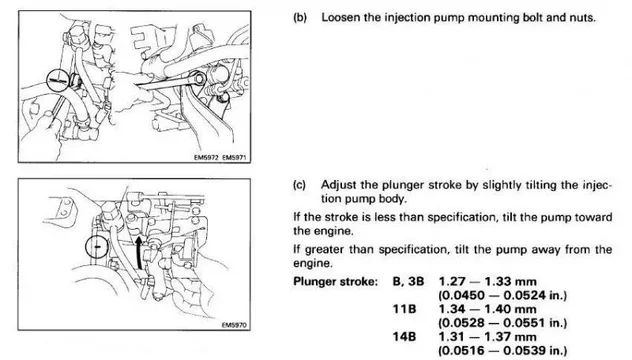

My old manuals, ( B,3B,11B,13B,13B-T) and (B, 2B), the timing is listed as 14 BTD for the B engine., NOW, my little problem child of a new B engine has an advance of 0 BTD on a tappet cover sticker.

0 deg at what RPM? idle, static-- No further info on the sticker

The only difference between the young and the old B engine which could affect timing would be the IP and I see some models have an advance mechanism built into the IP drive gear (called an Automatic Timer).

Mine has a rotary IP and a solid drive gear

Can I assume that the rotary pump has some sort of advance built in and would this 0 BTC advance therefore be a static setting.

All these questions:

Does anyone have a procedure for setting and or checking the timing on a post 1990 B series engine?

Perhaps mine should have the centrifugal timing gear for the IP. It's a long shot, but this was a bastardised engine !! ???

Is there a downloadable manual avail for this model??

George