I plan on servicing the front wiper motor as it's slow at times and seems noisier than it used to be. I may also pull the wiper link to clean and regrease it's joints while I'm in there as the cowl and wiper arms are already off. The link appears to be held in place by just six bolts, and it looks like it should slide out a square hole (about 4"x10") found under the cowl once it's disconnected from the body. The FSM does not go into any detail on how to remove the link so wondering if anyone has done this already who might know of any pitfalls or tips?? Thanks

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone know how to remove the front windshield wiper link?? (5 Viewers)

- Thread starter Kernal

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?The cowl is held by 6 - 8 screws once you open the hood. You need a very small phillips. Once you lift it up you will see the holes mentioned.

- Thread starter

- #3

Thanks, but I already have the cowl off, the wiper link is attached inside another boxed section ie: it still isn't completely visible with the cowl off. My guess is that the link will just slide out the rectangular hole once it's unbolted; just hoping to avoid any surprises like unseen fasteners flying off into the wilderness or dropping down a hole.

Chris FJ80

SILVER Star

Just pulled mine, so thought I would add a couple of pics

First pic is of the ball (motor side) and socket (link side) -- pull firmly and they separate

Second is how to position the linkage as you pull it through the hole in the passenger side

First pic is of the ball (motor side) and socket (link side) -- pull firmly and they separate

Second is how to position the linkage as you pull it through the hole in the passenger side

- Thread starter

- #5

I figured it out after the original post. I took the linkage out through the vent holes once the cowl was removed. I completely dismantled the linkage, cleaned and regreased the sockets using Molykote 33 Medium grease and painted the linkage. I also drilled out the wiper spindle shafts to make them greasable then cleaned, painted and regreased the bronze bushings that the shaft rotates in (inside the linkage mounts). I found when I first took the shafts out of the mounts that the original grease was gone and some corrosion was present on the wiper shafts. The wiper spindle shaft can now be easily regreased by just removing the cap nut that holds the wipers onto the shaft.

Last edited:

I also drilled out the wiper spindle shafts to make them greasable The wiper spindle shaft can now be easily regreased by just removing the cap nut that holds the wipers onto the shaft.

Very nice. I did a bunch similar stuff on my 60. I will copy. Thanks.

- Thread starter

- #7

When I pulled the mounts apart it was obvious that water was getting inside, I think the grease will help keep the water out now. The original lube for the shafts appeared to be a swipe of a graphite and/or Moly paste with a very small dab of yellow grease inside the mount. For lubing the shafts I first used a Moly aerosal and burnished (polished) the shafts (that's why they look shiny black), then applied Molykote GN assembly paste on the bushings and packed the interior cavity of the mounts with a mixture of Polyrex EM and Molykote G-4700. Those two greases are compatible, I mix them because the G-4700 (a longlife PAO grease with Moly and graphite) has a funky texture by itself, not very creamy, but by adding the PolyrexEM it smoothes right out. It doesn't show up in the photos but I also used a very small file to groove the small bushings to better allow the grease to flow into them from the center cavity of the mounts. FWIW.

Very cool. I am half-expecting you to cut some threads and add zerks next. JK.

- Thread starter

- #9

I actually considered adding a mini zerk to the side of the mounts but decided the easiest method was just drilling a bore hole down the center of the shaft then drill in from the side to meet up with the center hole. Grease will now come up in the center of the mount between the two bushings and out the front and back of the mounts, which should also push out any water that might get inside. This was more of a fun project, not really necessary as I greased the shaft and mount very well with essentially permanent Moly/graphite grease, but maybe 1/50 of an ounce of grease every year or two would keep it fresh.

Here's a link to a thread on servicing a wiper motor and getting it reconnected to the linkage, FWIW:

https://forum.ih8mud.com/80-series-...wiper-motor-after-16-years-300-000-miles.html

Here's a link to a thread on servicing a wiper motor and getting it reconnected to the linkage, FWIW:

https://forum.ih8mud.com/80-series-...wiper-motor-after-16-years-300-000-miles.html

@Kernal we're all older and wiser since you did this job on the wiper linkage. The problem i have is is when you turn on the wipers, they go down first then do the up swing. Once on they appear to work perfectly.

I have to install the wiper arms mybe 2" higher up the windshield to allow for the inital downward motion.

Before i rip into the linkage, can you remember of there is any specific install tips to follow to align the motor and the sweep?

I have to install the wiper arms mybe 2" higher up the windshield to allow for the inital downward motion.

Before i rip into the linkage, can you remember of there is any specific install tips to follow to align the motor and the sweep?

- Thread starter

- #11

Well it's been a minute (or closer to a dozen years) since I messed with a wiper motor and linkage. If the wipers aren't clocking themselves correctly four general possibilities come to mind, either a defective motor, an incorrect motor installation, a defective linkage, or incorrectly (re)installed wiper arms.

In the situation above it sounds like the motor is not cycling fully (going to it's end position) when it's turned off, so the next time the motor is energized it completes the previous incomplete cycle then starts over correctly (others with more electron experience could probably explain it better).

Point is you won't know for sure what the cause is until you start taking things apart. One quick solution would be to pick up a (good) used or aftermarket wiper motor to have on hand, stuff that in place of the current motor and see how it runs. That way you save the time of pulling everything apart to inspect and don't have to mess with repositioning the wiper arms.

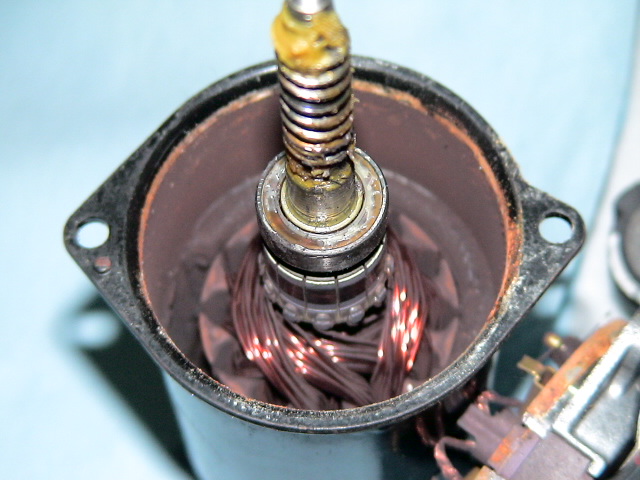

Below is a photo showing the wiper motor unbolted from the firewall but still connected to the wiper linkage.

It shows the correct (down/end) position of the wiper motor lever arm (Red arrow) pointing at ~9 O'clock (position) while connected to the wiper linkage ball socket pulled slightly out of the access hole (Green arrows) with the wipers in the full down (correct) position. IIRC.

Here's a link to a previous thread, the hardest part of the process IME was removing the wiper motor from the ball socket of the linkage (if it doesn't just pop out, which it might) so I used a modified tool to help pry the motor ball out of the socket. I discussed clocking the wiper arms in that thread but it appears your problem may not be with the wiper arms if they haven't been messed with.

forum.ih8mud.com

forum.ih8mud.com

In the situation above it sounds like the motor is not cycling fully (going to it's end position) when it's turned off, so the next time the motor is energized it completes the previous incomplete cycle then starts over correctly (others with more electron experience could probably explain it better).

Point is you won't know for sure what the cause is until you start taking things apart. One quick solution would be to pick up a (good) used or aftermarket wiper motor to have on hand, stuff that in place of the current motor and see how it runs. That way you save the time of pulling everything apart to inspect and don't have to mess with repositioning the wiper arms.

Below is a photo showing the wiper motor unbolted from the firewall but still connected to the wiper linkage.

It shows the correct (down/end) position of the wiper motor lever arm (Red arrow) pointing at ~9 O'clock (position) while connected to the wiper linkage ball socket pulled slightly out of the access hole (Green arrows) with the wipers in the full down (correct) position. IIRC.

Here's a link to a previous thread, the hardest part of the process IME was removing the wiper motor from the ball socket of the linkage (if it doesn't just pop out, which it might) so I used a modified tool to help pry the motor ball out of the socket. I discussed clocking the wiper arms in that thread but it appears your problem may not be with the wiper arms if they haven't been messed with.

Windshield wiper motor after 16 years and 300,000+ miles.

Thought I'd post up what I found when I pulled the original windshield wiper motor. It sometimes would run slower and was making a sorta growling noise which was more noticeable after I had removed the wiper arms. With the motor apart I found that the magnet on the bottom side of the case had...

forum.ih8mud.com

forum.ih8mud.com

Last edited:

Similar threads

Users who are viewing this thread

Total: 6 (members: 0, guests: 6)