Nice progress. I will hold off on selling my Mercedes until after I go for a ride.. maybe

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #23

Passed a milestone today: I have got all of the motor and transmission mounts complete. For the first time in almost a month, the FJ40 does not have jacks, straps or an engine hoist holding the drivetrain in place. It may just be me, but I think seeing it sit in the driveway without help is sexy. Don't know if it is sexier than David Hasselhoff in an orange Speedo, but that is a judgement call....

- Thread starter

- #24

Gotta love Oregon in spring. Walked face first into freshly budded (juicy) poison oak Monday. Had an embedded tick removed at ER Tuesday. Sank an excavator in mud Wednesday.

And due to rain, Ive done little on the FJ40 in weeks...

There are several threads on swapping a Mini-truck axle into an FJ40 on the internet, but all of the ones I had seen involve outboarding the springs, going SOA or other modifications. I am hoping to do this swap without modifying anything except the axle, in trying to keep the stock appearance/ride height as much as possible.

The issue is the football-shaped differential housing on the mini-truck axles. Because of this I had to modify the spring perch (see pic). Even grinding down the perch as much as possible, the axle is about 5/8" off center (towards the drivers side). I'm not seeing a lot of good options, and am totally open to suggestions.

One way would be to fabricate a taller perch (like a lowering kit) and compensating it with a slightly longer shackle (still running stock shackles, I estimate a 1-2" longer shackle would do it, so probably not enough to mess with the steering geometry or look too cheezy.

Or I could mount the axle 5/8" off-center and run a spacer on the passenger side. Not ideal.

I'm hoping someone has a better solution?

And due to rain, Ive done little on the FJ40 in weeks...

There are several threads on swapping a Mini-truck axle into an FJ40 on the internet, but all of the ones I had seen involve outboarding the springs, going SOA or other modifications. I am hoping to do this swap without modifying anything except the axle, in trying to keep the stock appearance/ride height as much as possible.

The issue is the football-shaped differential housing on the mini-truck axles. Because of this I had to modify the spring perch (see pic). Even grinding down the perch as much as possible, the axle is about 5/8" off center (towards the drivers side). I'm not seeing a lot of good options, and am totally open to suggestions.

One way would be to fabricate a taller perch (like a lowering kit) and compensating it with a slightly longer shackle (still running stock shackles, I estimate a 1-2" longer shackle would do it, so probably not enough to mess with the steering geometry or look too cheezy.

Or I could mount the axle 5/8" off-center and run a spacer on the passenger side. Not ideal.

I'm hoping someone has a better solution?

I have a variety of u-bolts if you want me to check for some long ones. Is there a possibility of building a bracket to bolt the spring to?

- Thread starter

- #26

Kief-thanks for the offer, but I just ordered new u-bolts and plates. It does look like I'll need to fabricate something for the inside u-bolt that is partially on the differential.

The axles are taking more time and energy than I hoped-and I am having a little anxiety as I am doing all of this without knowing for certain if the motor and trans are good.

The axles are taking more time and energy than I hoped-and I am having a little anxiety as I am doing all of this without knowing for certain if the motor and trans are good.

I also have a late 60's fj40 axle that was flipped to SOA- I know that isn't what you are looking for but if its the fine spline housing with the seals in the outer part vs. the bushings the mini truck stuff will bolt on AFAIK, free if you want it.

- Thread starter

- #28

I always remember seeing old-school hotrods and modified rigs where someone would find a way to shoehorn a 454 into a Vega, or big-block Buick into a Jeep. Based on how close the clearances are on this OM617/Toyota 5-speed/FJ40 swap are, don't know how, or why someone would try. Maybe just to prove it could be done?

The clearance issues I'm cstill fighting stem from my not wanting to lift the FJ40 either with springs or SOA, as well as the 5-speed instead of a more compact 4-speed. If I yielded on either of those, everything would be hunky-dory.

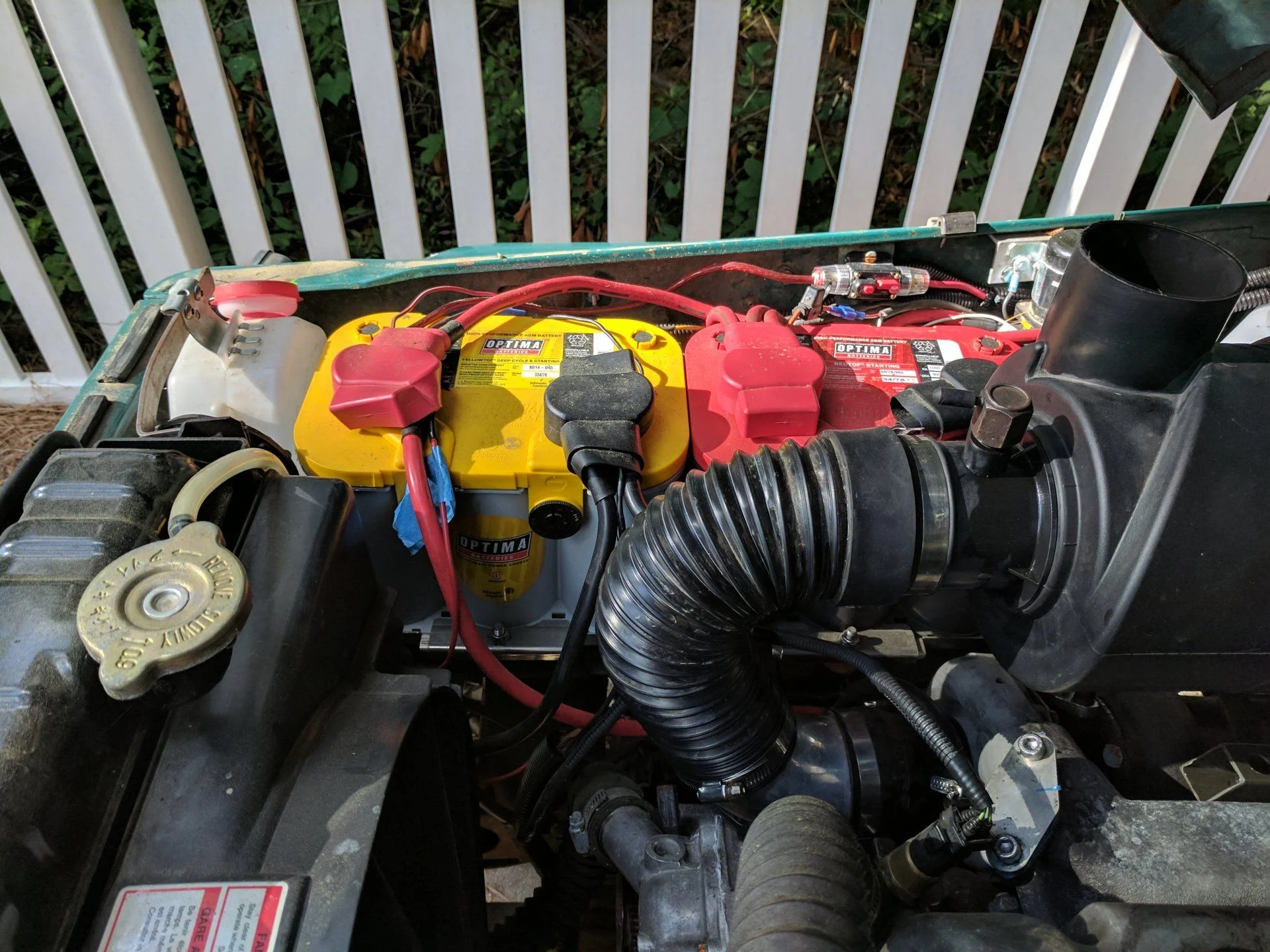

But, after mocking up the new radiator, it looks like there may be an issue with the lower radiator hose. There also does not appear to be room for a battery under the hood. May have to be creative:

The clearance issues I'm cstill fighting stem from my not wanting to lift the FJ40 either with springs or SOA, as well as the 5-speed instead of a more compact 4-speed. If I yielded on either of those, everything would be hunky-dory.

But, after mocking up the new radiator, it looks like there may be an issue with the lower radiator hose. There also does not appear to be room for a battery under the hood. May have to be creative:

I don't think you like easy.

It can be done, I didn't go 5 speed I'm running an h42 but otherwise similar set up-let me know if I can answer any questions.

The Nissan SD22 / Willys truck swap I did a few years back View attachment 1450665

I remember reading your thread about this! It was in a different forum dedicated to Nissan diesels I think. Maybe dyndns? It really caught my attention since I have an SD22 just waiting for me to find time to put it into a 1973 Datsun pickup, which my Dad bought brand new.

Putting the MB OM617 into a 40 also is something I find interesting. Someday I want to put a diesel into my 40. Currently my plans are to use a GM 6.2/6.5, but my second choice is a MB OM617. My biggest concern is the front sump that they have, and how to address clearance to the front axle pumpkin. My biggest concern would be in improving fuel mileage over the stock drivetrain, and keeping, or improving, the power and torque of the stock motor.

Don

- Thread starter

- #33

Don-the GM 6.2 -6.5 really is not a bad option, especially if you aren't one of those blessed folks who somehow have 50k to dump into a hobby...plus there is an endless variety of transmission options.

The SD22/Willys swap worked out great, I got the whole truck running for under 2k. It got slightly over 30 mpgs, and could cruise 55-60, which is a huge improvement over the stock Willys 4-banger's 12-13 mpg and top speed of 45. Downhill. With tailwind. At sea level. Stock Willys are truly dreadful machines-but despite their many quirks, I still love them and respect their place in 4x4 history.

Scott-nicely done. I see you are running both a yellow top and a red top: Are you using the yellow top for accessories, or are they running tandem? Also, any chance you could get a picture of your battery mount?

Lastly-quick shameless plug for Summit Racing. I ordered and Optima Red Top battery Thursday night. By the time I returned home from work Friday night, the battery was on my doorstep. This is the second item I have ordered from them they have delivered in less than 24 hours-with no shipping fee! If I were on top of my sh&% half as much as Summit Racing, this truck would be up and running by now.

The SD22/Willys swap worked out great, I got the whole truck running for under 2k. It got slightly over 30 mpgs, and could cruise 55-60, which is a huge improvement over the stock Willys 4-banger's 12-13 mpg and top speed of 45. Downhill. With tailwind. At sea level. Stock Willys are truly dreadful machines-but despite their many quirks, I still love them and respect their place in 4x4 history.

Scott-nicely done. I see you are running both a yellow top and a red top: Are you using the yellow top for accessories, or are they running tandem? Also, any chance you could get a picture of your battery mount?

Lastly-quick shameless plug for Summit Racing. I ordered and Optima Red Top battery Thursday night. By the time I returned home from work Friday night, the battery was on my doorstep. This is the second item I have ordered from them they have delivered in less than 24 hours-with no shipping fee! If I were on top of my sh&% half as much as Summit Racing, this truck would be up and running by now.

Don-the GM 6.2 -6.5 really is not a bad option, especially if you aren't one of those blessed folks who somehow have 50k to dump into a hobby...plus there is an endless variety of transmission options.

The SD22/Willys swap worked out great, I got the whole truck running for under 2k. It got slightly over 30 mpgs, and could cruise 55-60, which is a huge improvement over the stock Willys 4-banger's 12-13 mpg and top speed of 45. Downhill. With tailwind. At sea level. Stock Willys are truly dreadful machines-but despite their many quirks, I still love them and respect their place in 4x4 history.

I already have a 94 Chev K2500 with the first year of the 6.5 and electronic IP. Because of gearing I don't get but around 13+ MPG, but it is my workhorse. This pickup is why I've considered the 6.2/6.5 for my 40, and am counting on different gearing helping me get better MPG.

The Chevy pickup is also why I got the SD-22 to put into the 73 Datsun pickup. My intro to diesels has me convinced, and now I want the mileage that comes with a small diesel motor. My biggest question right now is the final drive ratio for the Datsun. The gasser Datsun apparently had 4.375 rear gears(specs for that year). The 81 (82?) Nissan that the motor/transmission came out of apparently had 3.88 rear gears. I have found out that Datsun/Nissan had drop out pumpkins just like Toyota did.

So, with further digging, I found that Nissan had several different gears available. What I'm hoping is that you can give some indication as to what gears, tire size you had in the Willy's. Yes, I'm being lazy. I'm hoping I don't have to try and remember/find what forum and thread your original swap was.

Don

I used this frame mount ( BATTERY TRAY ASSEMBLY TOY FJ40 LAND CRUISER FRAME MOUNT – BTB Products ) for the battery tray from BTB

Along with a dual optima tray from stainless trays ( StainlessTrays.com )

I will try and get pics later today.

Along with a dual optima tray from stainless trays ( StainlessTrays.com )

I will try and get pics later today.

- Thread starter

- #36

Scott-thanks for the link, looks like a good setup. I'm waffling between trying to fab something similar, or just buying that one. I am curious though, with only one mounting leg does it feel flimsy?

Don-I think the 4.375s would work-you aren't going to have great highway speed anyway, and the lower ratio will tighten up the spaces between gears. I ran 5.38s in the Willys, but it is hard to say how that would compare with yours as I had 33" tires and lost a to of power in the divorced transfer case.

Not sure I like the new bling...

Don-I think the 4.375s would work-you aren't going to have great highway speed anyway, and the lower ratio will tighten up the spaces between gears. I ran 5.38s in the Willys, but it is hard to say how that would compare with yours as I had 33" tires and lost a to of power in the divorced transfer case.

Not sure I like the new bling...

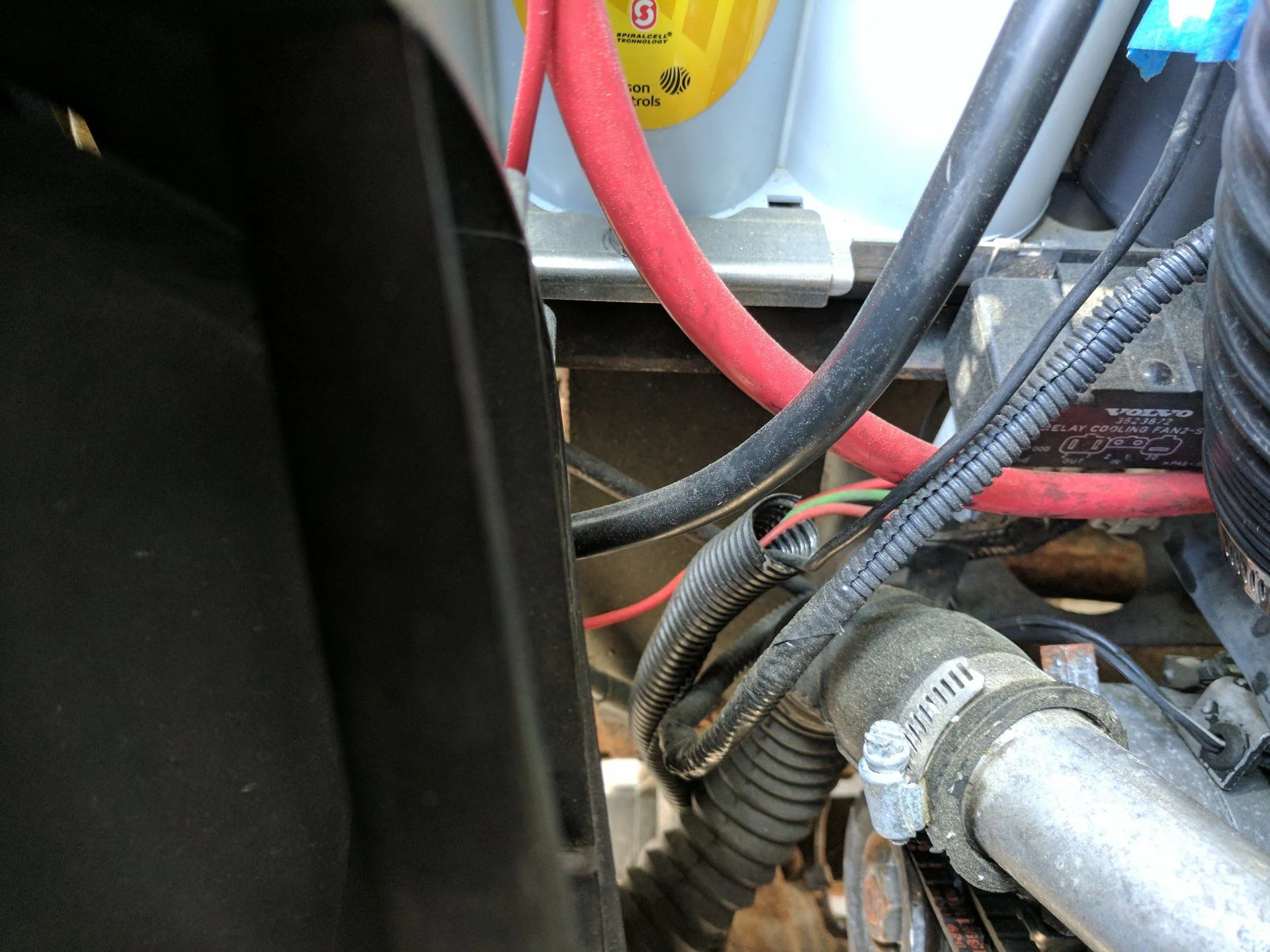

I forgot to answer about the batteries-I have the yellow as the main battery and the red is just for the glow plugs and starter. I am using a solenoid setup from 12voltguy for the isolation.

Pics are crappy-it is reeeeeaaaaallllly tight-as far as the stability goes, the btb bracket is pretty stout, I have had no issues.

Pics are crappy-it is reeeeeaaaaallllly tight-as far as the stability goes, the btb bracket is pretty stout, I have had no issues.

- Thread starter

- #38

Lately I seem to be caught in two cycles:

Buying things for this project that don't fit.

Starting something-then getting stuck when I run into an issue.

Goes without saying, but most of these are my fault....

like the Toyota driveshafts I purchased, cut, welded, then found out that the yoke on the 1985 Toyota truck transfer case has a different bolt pattern than the Toyota driveshafts from a similar year...never knew there was more than one pattern on pre 1985 trucks ($100 wasted)

Or the later model fj40 gas tank-that doesn't work with the stock bench seats. ($50 wasted)

But am making progress-I was able to modify the original battery mount to install an Optima battery to work with the turbo, got the radiator and power steering pump installed. Pulled the oilpan and cut off a corner to improve clearance over the differential, need to find a local welder who can weld it so it seals but doesn't get warped (certainly above my skill level for welding).

and I think I finally figured out the throttle linkage-it was a little intimidating as it has so many parts and was thrown in a box of stuff, but think most of it can be adapted.

Buying things for this project that don't fit.

Starting something-then getting stuck when I run into an issue.

Goes without saying, but most of these are my fault....

like the Toyota driveshafts I purchased, cut, welded, then found out that the yoke on the 1985 Toyota truck transfer case has a different bolt pattern than the Toyota driveshafts from a similar year...never knew there was more than one pattern on pre 1985 trucks ($100 wasted)

Or the later model fj40 gas tank-that doesn't work with the stock bench seats. ($50 wasted)

But am making progress-I was able to modify the original battery mount to install an Optima battery to work with the turbo, got the radiator and power steering pump installed. Pulled the oilpan and cut off a corner to improve clearance over the differential, need to find a local welder who can weld it so it seals but doesn't get warped (certainly above my skill level for welding).

and I think I finally figured out the throttle linkage-it was a little intimidating as it has so many parts and was thrown in a box of stuff, but think most of it can be adapted.

- Thread starter

- #39

Don't remember if I mentioned it, but it is my goal to have this old FJ40 up and running by August. And, I'm still hoping to put it all together-including the truck, turbo diesel motor, 5-speed transmission, axles and whatnot for less than 5k.

As they would say in the Baja, where I hope to take this truck next year, vamos a ver!

As they would say in the Baja, where I hope to take this truck next year, vamos a ver!

- Thread starter

- #40

Sooo, been having issues getting my new phone to share pics. Seems that once they go to "the cloud", I can't retrieve them...

The last week or so have been working on plumbing the brake and clutch lines. I'm upgrading all of the lines to 10mm with 3/16 line, which is fine and dandy, but I didn't do myself any favors when I sourced the clutch and brake master: the brake master is a Corvette master cylinder I chose because it is one of the only master cylinders designed to operate disc brakes without a booster. The clutch is stock 1960s FJ40.

The issue is that the FJ40 clutch master has the weird 11mm x 1.25 thread. No such brake line nut can be found in southern Oregon, and I only found one source online...been waiting almost two weeks for one nut.

The Corvette brake master has a 1/

2 and 9/16 fitting with unusual threads...so in a nutshell it took several weeks to research and find the parts.

Apologies for the formatting, difficult to edit on phone while eating pizza and drinking a beer.

The last week or so have been working on plumbing the brake and clutch lines. I'm upgrading all of the lines to 10mm with 3/16 line, which is fine and dandy, but I didn't do myself any favors when I sourced the clutch and brake master: the brake master is a Corvette master cylinder I chose because it is one of the only master cylinders designed to operate disc brakes without a booster. The clutch is stock 1960s FJ40.

The issue is that the FJ40 clutch master has the weird 11mm x 1.25 thread. No such brake line nut can be found in southern Oregon, and I only found one source online...been waiting almost two weeks for one nut.

The Corvette brake master has a 1/

2 and 9/16 fitting with unusual threads...so in a nutshell it took several weeks to research and find the parts.

Apologies for the formatting, difficult to edit on phone while eating pizza and drinking a beer.

Last edited:

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)