I posted this over on CL as well. If anyone has anything custom for their 460 and is willing to share... I'd like to print it

================================

Surely many in this group have 3D printers... I finally decided to dive into one.

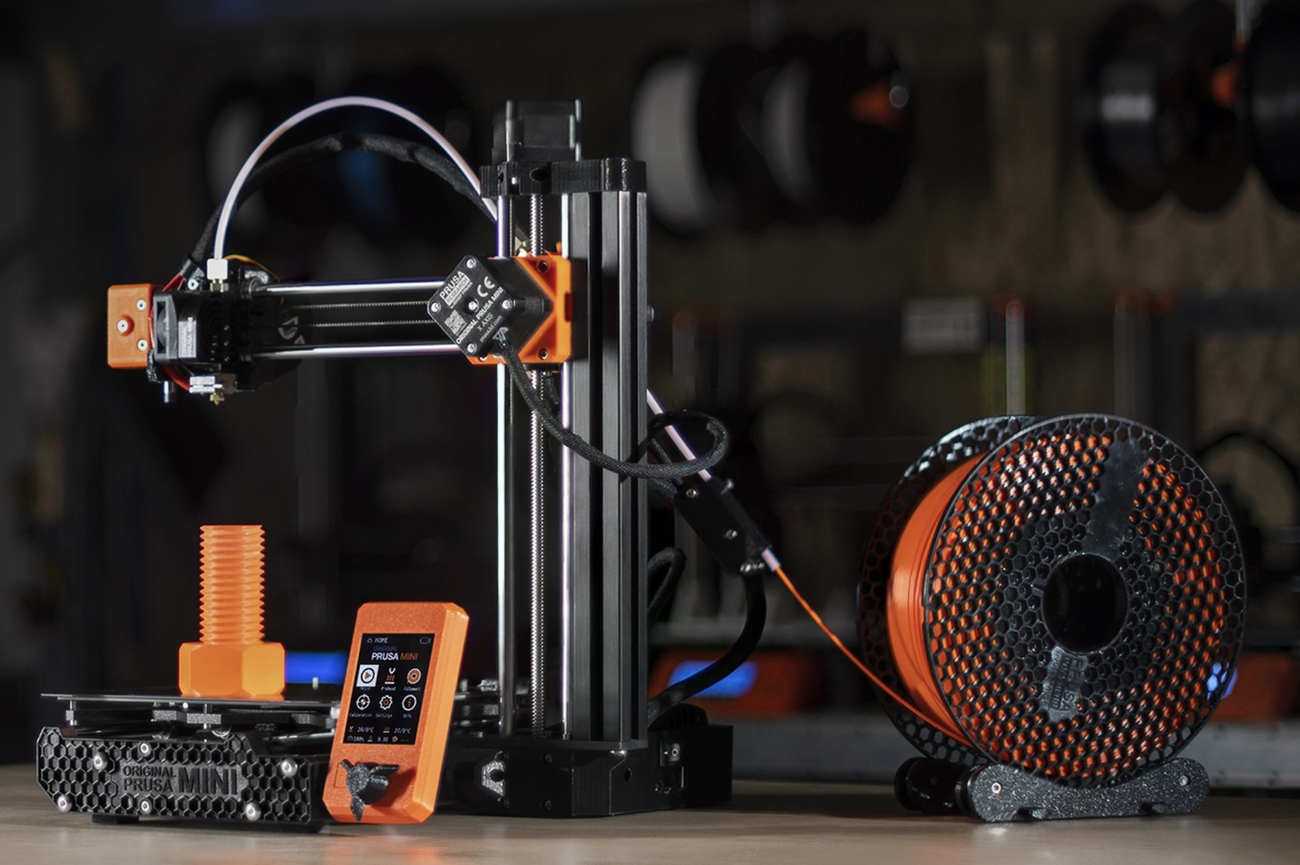

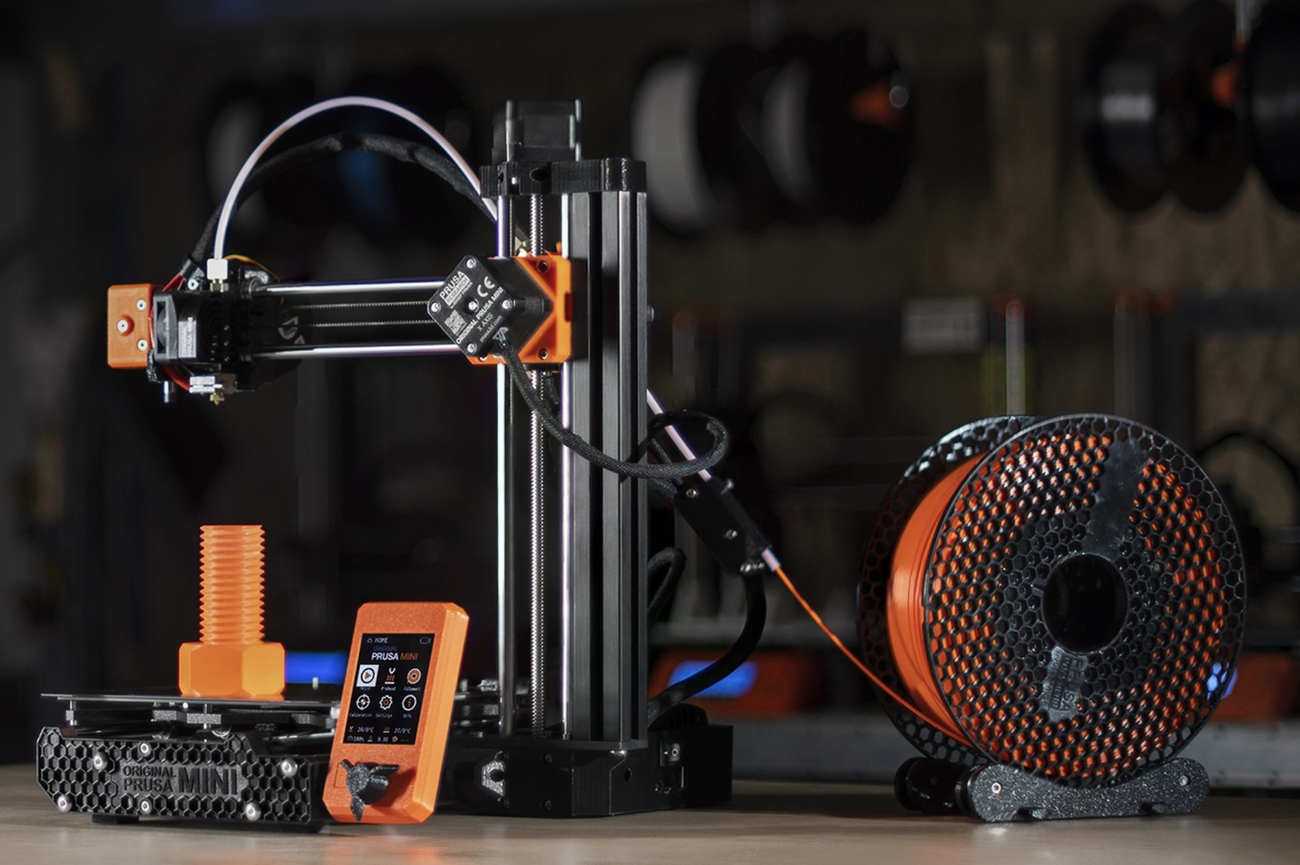

I've been playing around with a new Prusa Mini+ manufactured in the Czech Republic.

I hadn't heard of of Prusa before but frankly wasn't in the market for a 3D printer.. a friend turned me onto them.

I've got a lot to learn but just having fun printing some random stuff out.

I thought it may be good to start up a thread for parts developed specifically for our rigs.

I'd like print out a few 460 models I have seen.

Lexus GX460 by lynts - https://www.thingiverse.com/thing:3157747

Lexus GX460 free 3d model - download obj file - https://3dmag.org/en/market/item/6070/

Lexus GX460 3D Model - 3D CAD Browser - https://www.3dcadbrowser.com/3d-model/lexus-gx460

I saw the awning bracket project here.. I'll have to look back in threads to see if this was done by a CL or IH8mud member or not.

Awning brackets for Lexus GX 460 stock roof rails by 1974Boler - https://www.thingiverse.com/thing:5023748

Some 3D printing libraries of misc items

Thingiverse - Digital Designs for Physical Objects - https://www.thingiverse.com/

Discover STL files for 3D printing ideas and high-quality 3D printer models. | MyMiniFactory - https://www.myminifactory.com/

Cults・Download free 3D printer models・STL, OBJ, 3MF, CAD - https://cults3d.com/en

3D Models for Professionals :: TurboSquid - https://www.turbosquid.com/

Printables - https://www.printables.com/

================================

Surely many in this group have 3D printers... I finally decided to dive into one.

I've been playing around with a new Prusa Mini+ manufactured in the Czech Republic.

I hadn't heard of of Prusa before but frankly wasn't in the market for a 3D printer.. a friend turned me onto them.

I've got a lot to learn but just having fun printing some random stuff out.

I thought it may be good to start up a thread for parts developed specifically for our rigs.

I'd like print out a few 460 models I have seen.

Lexus GX460 by lynts - https://www.thingiverse.com/thing:3157747

Lexus GX460 free 3d model - download obj file - https://3dmag.org/en/market/item/6070/

Lexus GX460 3D Model - 3D CAD Browser - https://www.3dcadbrowser.com/3d-model/lexus-gx460

I saw the awning bracket project here.. I'll have to look back in threads to see if this was done by a CL or IH8mud member or not.

Awning brackets for Lexus GX 460 stock roof rails by 1974Boler - https://www.thingiverse.com/thing:5023748

Some 3D printing libraries of misc items

Thingiverse - Digital Designs for Physical Objects - https://www.thingiverse.com/

Discover STL files for 3D printing ideas and high-quality 3D printer models. | MyMiniFactory - https://www.myminifactory.com/

Cults・Download free 3D printer models・STL, OBJ, 3MF, CAD - https://cults3d.com/en

3D Models for Professionals :: TurboSquid - https://www.turbosquid.com/

Printables - https://www.printables.com/