Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Guru weigh-in: EFI

- Thread starter disassociative

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #2

- Thread starter

- #3

I am not sure about the egr. When I did my rebuild it was after 300,000 miles so my egr was way gummed up. I just used one off of a new low mileage 3FE.

The injectors you don't need to replace just send them to a place like RC Engineering to have them cleaned and tested and reuse them if they are all good. That is one place that I thought of off the top of my head here in ca but there are many others that can do the same job. Also change all the o-rings and rubber gromets and bushings that attach the injectors to the fuel rail and to the intake manifold. Most likely they are all toast.

The injectors you don't need to replace just send them to a place like RC Engineering to have them cleaned and tested and reuse them if they are all good. That is one place that I thought of off the top of my head here in ca but there are many others that can do the same job. Also change all the o-rings and rubber gromets and bushings that attach the injectors to the fuel rail and to the intake manifold. Most likely they are all toast.

LAMBCRUSHER

SILVER Star

dude, don't put it back together without having those injectors done...unless you really don't mind buying gaskets and spinning wrenches. I am holding off on getting into that rats nest till I have every gasket o ring and injector that could need changing while I'm in there.....

- Thread starter

- #7

Just a little blow by. The injectors can be serviced.

Great news, I'll be sure to get them serviced!

Also change all the o-rings and rubber gromets and bushings that attach the injectors to the fuel rail and to the intake manifold. Most likely they are all toast.

Will do.

dude, don't put it back together without having those injectors done...

Yeah, I knew I was going to have to do something with them...glad they don't need to be replaced. I have time to send them off, I'll look into doing that as Aseif says.

- Thread starter

- #8

Some background on my '88 FJ62

What I've done and why I've got the air intake off to begin with:

a) Very difficult to start, cranks ok. Fuses checked. Purrs like a kitten when she's warmed up and then starts no problem.

b) Code 22 (water temp sensor) on ECU, sensor is fine...besides being connected to the wrong connector. Voltages at the ECU did not read like they should, per FSM, when troubleshooting. After tracing the wires for the sensor from the ECU I realized that the right connector was just laying on the engine block and some other one (looks just like it only green instead of brown, will post a pic this afternoon) was connected. There is no continuity for the correct connector, so the intake had to come off.

c) Replaced most vacuum hoses. There is one hose that comes off the engine oil dipstick that I can't identify. It seems to go to the transmission, but I can't find it in any of the FSMs other than a reference when checking for vacuum leaks. EGR R Port does not generate vacuum under any operating condition.

d) Replaced spark plugs (all looked normal, gaps too large), checked distributor and high-tension wires. Disassembled and repaired wiring at elec connector (from ECU) at distributor as it was nearly separated at the terminal.

e) Adjusted valves--first while cold, then twice while warm--and timing. Runs great if you can get her going.

f) Fuel system overhaul - New wiring and ground connection for fuel pump, new fuel pump bracket, all new fuel lines from tank to filter (delivery) and rail to tank (return), new fuel filter. Fuel pump working correctly, pressure as specified.

g) Replaced bad Cold Start Injector with one from low-mileage 62. All specs good, per FSM. Cold Start Injector Time Switch resistance is as specified.

h) New Fuel Pressure Regulator (Carter)

i) New Throttle Position Sensor (Beck/Arnley). Adjusted per FSM when installed and cleaned throttle body.

j) Cleaned and checked Air flow meter. All specs good, per FSM.

k) Checked Oxygen Sensors, resistance is as specified.

What I've done and why I've got the air intake off to begin with:

a) Very difficult to start, cranks ok. Fuses checked. Purrs like a kitten when she's warmed up and then starts no problem.

b) Code 22 (water temp sensor) on ECU, sensor is fine...besides being connected to the wrong connector. Voltages at the ECU did not read like they should, per FSM, when troubleshooting. After tracing the wires for the sensor from the ECU I realized that the right connector was just laying on the engine block and some other one (looks just like it only green instead of brown, will post a pic this afternoon) was connected. There is no continuity for the correct connector, so the intake had to come off.

c) Replaced most vacuum hoses. There is one hose that comes off the engine oil dipstick that I can't identify. It seems to go to the transmission, but I can't find it in any of the FSMs other than a reference when checking for vacuum leaks. EGR R Port does not generate vacuum under any operating condition.

d) Replaced spark plugs (all looked normal, gaps too large), checked distributor and high-tension wires. Disassembled and repaired wiring at elec connector (from ECU) at distributor as it was nearly separated at the terminal.

e) Adjusted valves--first while cold, then twice while warm--and timing. Runs great if you can get her going.

f) Fuel system overhaul - New wiring and ground connection for fuel pump, new fuel pump bracket, all new fuel lines from tank to filter (delivery) and rail to tank (return), new fuel filter. Fuel pump working correctly, pressure as specified.

g) Replaced bad Cold Start Injector with one from low-mileage 62. All specs good, per FSM. Cold Start Injector Time Switch resistance is as specified.

h) New Fuel Pressure Regulator (Carter)

i) New Throttle Position Sensor (Beck/Arnley). Adjusted per FSM when installed and cleaned throttle body.

j) Cleaned and checked Air flow meter. All specs good, per FSM.

k) Checked Oxygen Sensors, resistance is as specified.

- Thread starter

- #9

While I've got her apart, I plan to do the following:

1) Service injectors

2) Repair/replace wiring as-needed

3) Re-bundle the wiring harness that is covered by the air intake chamber and identify mystery connector (see below)

4) Replace all gaskets, grommets, o-rings, etc...

5) New fasteners

6) Thorough cleaning of air intake chamber

7) Troubleshoot smog components...possible desmog...

8) Clean and coat rusty fuel, coolant and vacuum hard lines

9) New fuel and radiator hoses

10) Inspect ISC valve

11) Replace Fuel Injection Pressure Damper

I'd love to hear from anyone with suggestions about additional work to do while I'm at this point. Given how difficult it is to access, and all the carbon I'm seeing in the Air Intake Chamber, I'm considering pulling off the Intake Manifold for a cleaning as well...

Thanks in advance!

1) Service injectors

2) Repair/replace wiring as-needed

3) Re-bundle the wiring harness that is covered by the air intake chamber and identify mystery connector (see below)

4) Replace all gaskets, grommets, o-rings, etc...

5) New fasteners

6) Thorough cleaning of air intake chamber

7) Troubleshoot smog components...possible desmog...

8) Clean and coat rusty fuel, coolant and vacuum hard lines

9) New fuel and radiator hoses

10) Inspect ISC valve

11) Replace Fuel Injection Pressure Damper

I'd love to hear from anyone with suggestions about additional work to do while I'm at this point. Given how difficult it is to access, and all the carbon I'm seeing in the Air Intake Chamber, I'm considering pulling off the Intake Manifold for a cleaning as well...

Thanks in advance!

1911

chupacabra

These guys did great work on my FJ80 3FE injectors, and were very reasonably priced I thought: WitchHunter Performance - Injector Cleaning & Flow Testing Services

- Thread starter

- #11

Thanks for the lead 1911, $21 per is pretty good next to the cost of new ones.

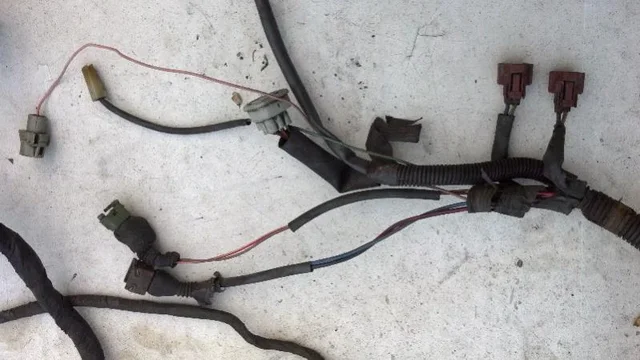

Got the wire harness out, pretty fugly. Top (or left, not sure if app auto-rotates images) two connectors, one brown and one green, are the ones I talked about above. Green is for water temp sensor, not sure about the other...maybe A\C.

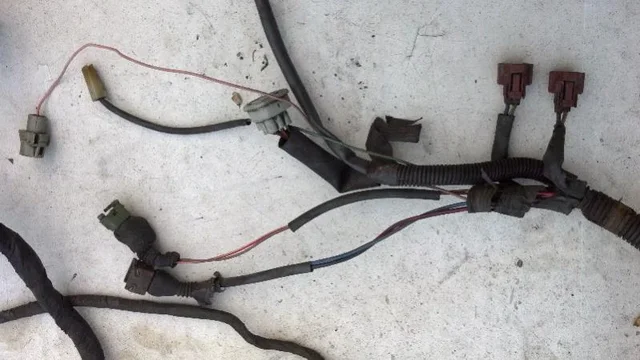

Think I'll completely redo this, the shot below is pretty typical of the wiring on this rig. Sure hope that's the ground...

Got the wire harness out, pretty fugly. Top (or left, not sure if app auto-rotates images) two connectors, one brown and one green, are the ones I talked about above. Green is for water temp sensor, not sure about the other...maybe A\C.

Think I'll completely redo this, the shot below is pretty typical of the wiring on this rig. Sure hope that's the ground...

- Thread starter

- #12

Josie'sLandCruiser

Stop calling it a "FJ."

Hi All:

Wait until they are teenagers!

Sorry, couldn't resist!

Good luck with your injecters.

Alan

Wait until they are teenagers!

Sorry, couldn't resist!

Good luck with your injecters.

Alan

- Thread starter

- #14

Josie'sLandCruiser said:Wait until they are teenagers!

Yikes...only one of them is tall enough to drive the mower. But now that you mention it, the first thing she said when she was done was "can I drive that truck now? I could take everyone at the same time!"

Great handle btw, the youngest's name is Josie.

- Thread starter

- #15

Can anybody recommend a method or product for cleaning the inside of the air intake chamber?

Carb & choke cleaner doesn't really cut it, seems like a big investment to go that way at this rate.

Thanks

Carb & choke cleaner doesn't really cut it, seems like a big investment to go that way at this rate.

Thanks

- Thread starter

- #16

So, the mystery is solved. The unidentified connector belongs on the cold start injector time switch. Could this being disconnected explain why the engine is so hard to start?

Seems like it could explain some of the build up on the EGR, due to rich fuel mixture...right?

Opened and combed through the wire harness today. There is a small break in the casing on one of the wires for the water temp sensor, but nothing that seems like it could result in an ECU code. I'll check the sensor again.

Here's the FSM info just for fun.

Seems like it could explain some of the build up on the EGR, due to rich fuel mixture...right?

Opened and combed through the wire harness today. There is a small break in the casing on one of the wires for the water temp sensor, but nothing that seems like it could result in an ECU code. I'll check the sensor again.

Here's the FSM info just for fun.

- Thread starter

- #17

Forgot to mention that the diagram also shows the water temp sensor, it's to the left of the cold start injector time switch.

So, the mystery is solved. The unidentified connector belongs on the cold start injector time switch. Could this being disconnected explain why the engine is so hard to start?

Yep, it tells the ECU whether it's cold enough to fire the CSI and limits it to a few seconds to avoid flooding. You should pull it verify the resistances, if you still have starting trouble after hooking it up.

- Thread starter

- #19

Yep, it tells the ECU whether it's cold enough to fire the CSI and limits it to a few seconds to avoid flooding. You should pull it verify the resistances, if you still have starting trouble after hooking it up.

Sweet, thanks Bill. I'll probably pull the sensor and check it anyway just to make sure I know where it is...probably should have looked a bit harder for it

ntsqd

technerd

Hot tank the intake if you can easily remove and replace all of the electric components. Then have it Extrude Honed.......

It's unfair you know, I can't talk SWMBO into one Airstream and there you have two of them.

It's unfair you know, I can't talk SWMBO into one Airstream and there you have two of them.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)