So it's high time I started my own thread for the build up of the RastaRig here ....

I'm still fairly new to the IH8Forum and gotta say that after taking good looks at all the work you guys are doing here....I'm humbled. I can only hope to aspire to the level of craftsmanship many of you show!

I bought this about 12 years ago and needed a commute vehicle. It was pretty stock with literally nothing done to it. Looked nice ran OK but I was soon to find out that the manifold/exhaust configuration on the 2F leaves alot to be desired. LOL! In 1998 I had just moved to the bay area and the congestion of one-way commutes of an hour or more along with the exhaust leak was quite literally killing me after about 6 months.

To make a long story short there, after much beltsander attacks on manifolds, dicking around with shop manual electrical & vac diagrams, quite literally marking every hose and futile attempts to track down all sorts of innocuous, buggy little behaviors----

I gave up. Didn't like the engine anymore. Didn't even like driving the thing. It was parked in my driveway. A smog year came around and I knew this was it. So, I decided to do a transplant and so began this journey....2005, five years ago. I did a spring over at some point and then the 2F was pulled out with the tranny ....sold. At this point, the rig was towed and so begins our journey.

I wish in hindsight I had taken more pics back then..... maybe BECAUSE of that I'm kind of a pic whore now and so please know that I'm fighting putting up too many pics here I'll try not to be wordy too. I have a problem with that.

I'll try not to be wordy too. I have a problem with that.

------------------------------------

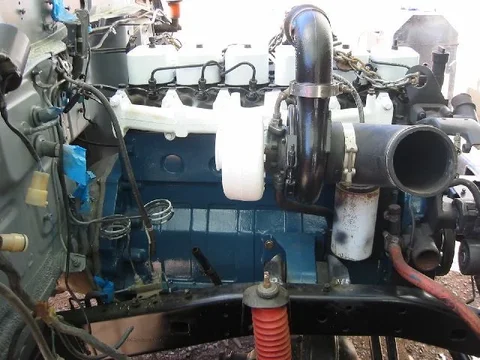

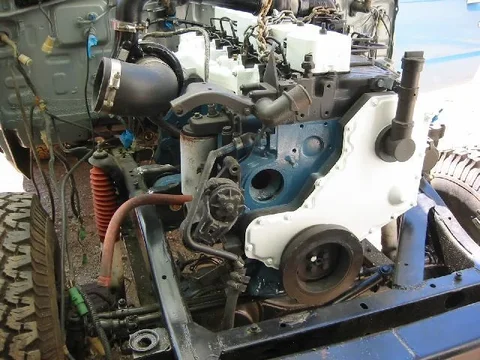

These are a couple of views sans engine and how that start initially looked:

I'm still fairly new to the IH8Forum and gotta say that after taking good looks at all the work you guys are doing here....I'm humbled. I can only hope to aspire to the level of craftsmanship many of you show!

I bought this about 12 years ago and needed a commute vehicle. It was pretty stock with literally nothing done to it. Looked nice ran OK but I was soon to find out that the manifold/exhaust configuration on the 2F leaves alot to be desired. LOL! In 1998 I had just moved to the bay area and the congestion of one-way commutes of an hour or more along with the exhaust leak was quite literally killing me after about 6 months.

To make a long story short there, after much beltsander attacks on manifolds, dicking around with shop manual electrical & vac diagrams, quite literally marking every hose and futile attempts to track down all sorts of innocuous, buggy little behaviors----

I gave up. Didn't like the engine anymore. Didn't even like driving the thing. It was parked in my driveway. A smog year came around and I knew this was it. So, I decided to do a transplant and so began this journey....2005, five years ago. I did a spring over at some point and then the 2F was pulled out with the tranny ....sold. At this point, the rig was towed and so begins our journey.

I wish in hindsight I had taken more pics back then..... maybe BECAUSE of that I'm kind of a pic whore now and so please know that I'm fighting putting up too many pics here

------------------------------------

These are a couple of views sans engine and how that start initially looked:

Last edited: