- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #41

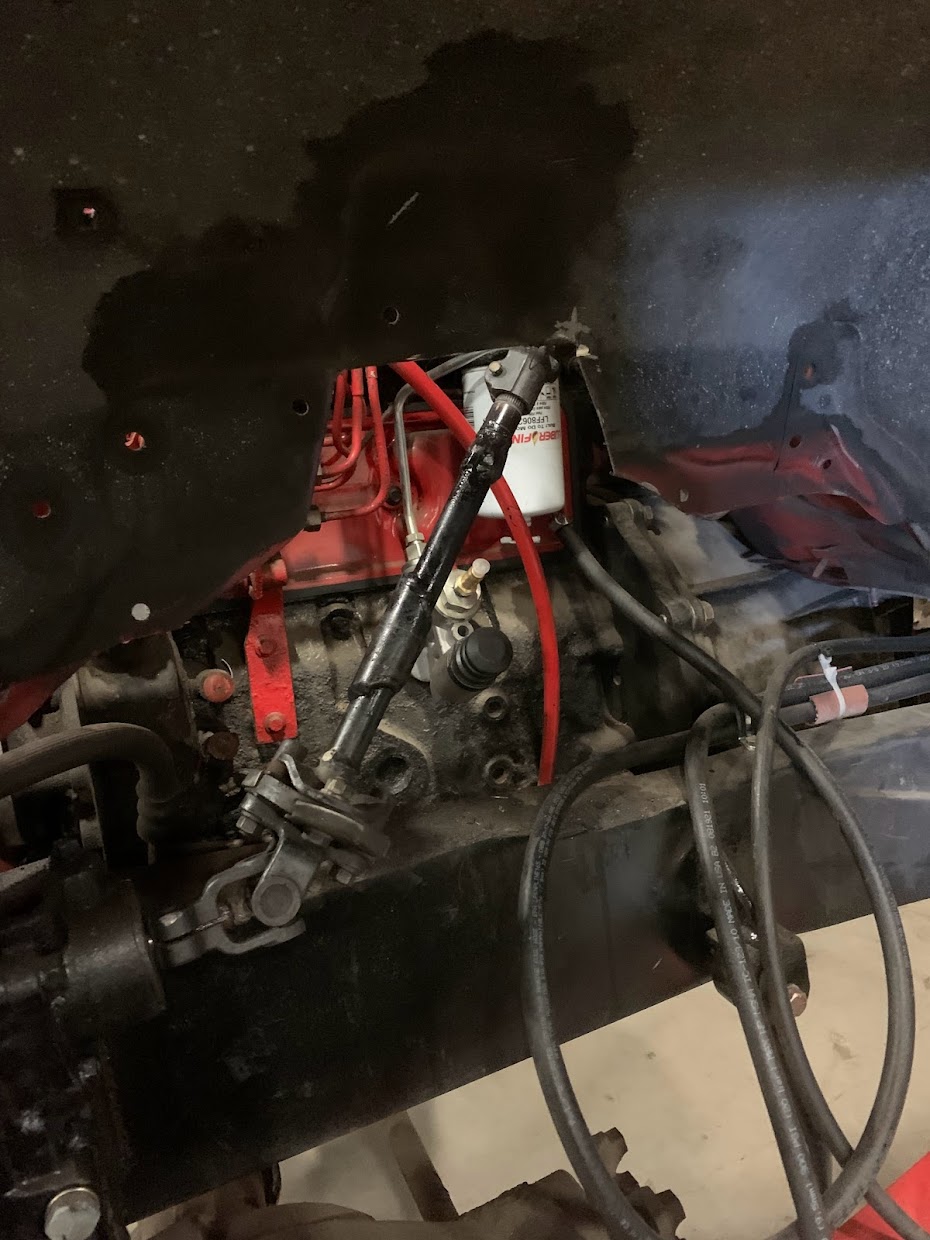

After moving the truck around the shop the other day, I decided I needed to get the steering hooked up before anything else in case I want to move it around.

A vice grip on a steering shaft was no fun.

So I set about getting the steering hooked up, fortunately I had both steering shafts to splice together to make one new one.

Everything works great with no binding on the U-joints, however I am going to install a flanged bearing where the shaft passes through the firewall to add some extra support. With the current setup and the additional U-joint by the firewall it moves around a little too much for my liking. Fortunately they are cheap and I have one on the way from amazon.

Next on the list is flexing it out for the front shock mount locations and measuring for the rear shocks. When I was shoving it over to its spot the other day I grabbed the forklift and flexed it a little, seems like the suspension is going to work out very nicely.

A vice grip on a steering shaft was no fun.

So I set about getting the steering hooked up, fortunately I had both steering shafts to splice together to make one new one.

Everything works great with no binding on the U-joints, however I am going to install a flanged bearing where the shaft passes through the firewall to add some extra support. With the current setup and the additional U-joint by the firewall it moves around a little too much for my liking. Fortunately they are cheap and I have one on the way from amazon.

Next on the list is flexing it out for the front shock mount locations and measuring for the rear shocks. When I was shoving it over to its spot the other day I grabbed the forklift and flexed it a little, seems like the suspension is going to work out very nicely.