spotcruiser

Geezer

Whenever I need to weld something that is galvanized, zinc plated, or cad plated, I soak it in phosphoric acid until the reaction and foaming stop. Then I clean it up with a scotch-brite grinder pad and weld away. I try to be as careful as I can be with welding fumes all the time, though.

I hate the fact that the unistrut comes electro-galvanized. Ever try fitting a respirator under a welding hood? Fortunately the shop has good ventilation, proven by a smoke test at the weld site before actual welding took place...

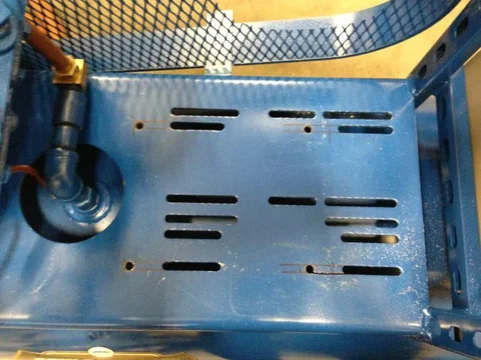

Pictures tonight hopefully.