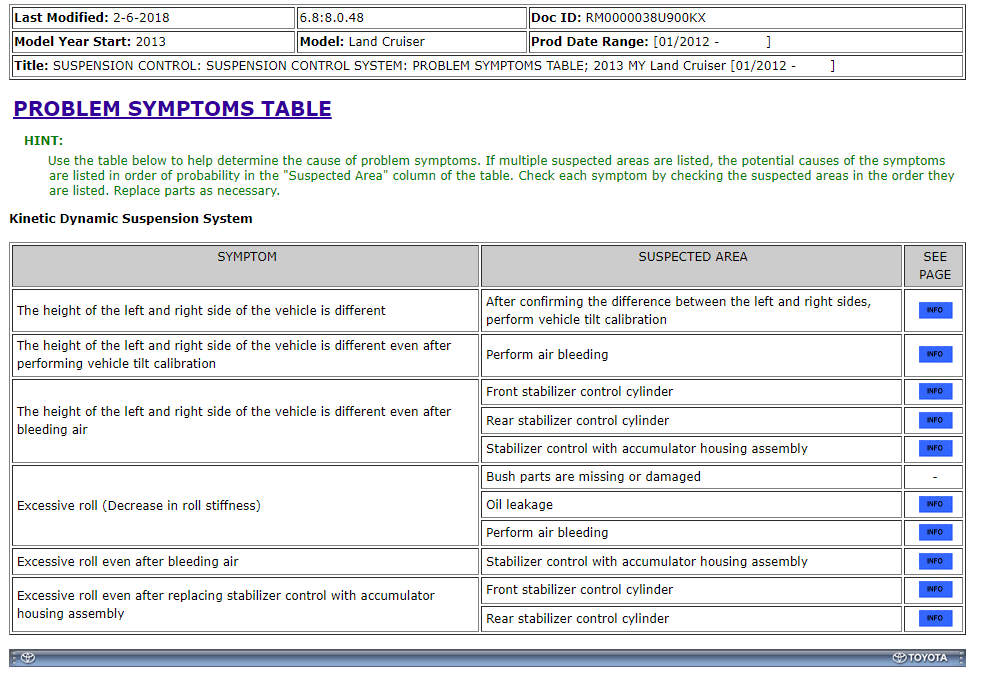

What's interesting is that this isn't any sort of expected failure mode for KDSS. Everything in that case points to too much body roll if there's air in the system, not an overly firm system.

It's certainly possible this is a KDSS failure of course, especially since you get a bit of fluid weeping by when you start to open the valves. Maybe the accumulator is frozen? They are supposed to have a gas inside which will allow for fluid to expand into it, but if it's stuck, or if the air somehow migrated out and so the accumulators are filled only with oil, perhaps that's why it gets stiff?

It's certainly possible this is a KDSS failure of course, especially since you get a bit of fluid weeping by when you start to open the valves. Maybe the accumulator is frozen? They are supposed to have a gas inside which will allow for fluid to expand into it, but if it's stuck, or if the air somehow migrated out and so the accumulators are filled only with oil, perhaps that's why it gets stiff?