I couldn't sleep thinking about this odd 'S' terminal, and then I had the

light go on. Actually, Tom seems to have slightly beaten me to the punch here, but a

is a

so here goes....

The issue was confounding because I couldn't see the sense in manufacturing a relay with a dummy terminal, and then hooking a wire to it. From a manufacturing perpective, why spend the money? Why design something like that?

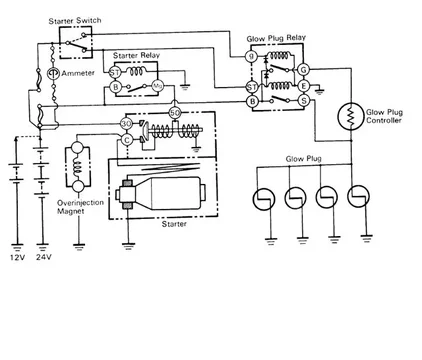

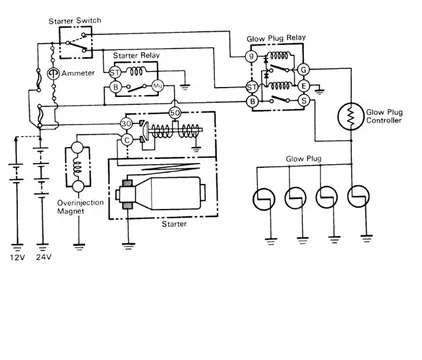

Now, Tom (Lost Marbles) brought to my attention a misapprehension that I was laboring under, namely that the controller was wired in parallel, just like the glow plugs. Well, it

isn't - it's wired in series, to the glow plugs, which are themselves wired in parallel. Thus a whole bunch of stuff was suddenly cleared in my mind - - though this dummy 'S' terminal was still making no sense.

Drew, in a discussion on another thread had suggested the harnesses were used in both fixed delay and Superglow applications, which i knew to be wrong. However, thinking about the wiring diagram, and how it uses the phrase '12v/24v.' to label only the battery (the rest of the wiring being the same for both applications obviously), and then casting my mind back to the BJ40 harness I took all apart, a 24v. harness, and remembering how it

was pretty much the same as my own HJ47 harness, save for the added resistor for the cig. lighter and the transformer for the radio - - well, clearly Toyota

does use the same harness for 12v. and 24v. applications. I'm sure they do this to streamline production and realize economy. Drew was correct about the multiple use of one harness.

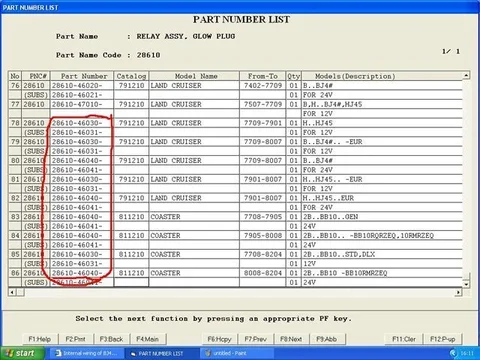

In other words, the base harness must be a 24v. harness, and that is really what was illustrated in the HJ45 wiring diagram - including the internal wirng for the glow relay. For 12v. applications, a 12v. glow relay is fitted, and in order to deal with the cable end (the black-yellow returning from the controller and going out to the plugs) that attaches to the functional 'S' terminal on a 24v. relay, Toyota simply specifies a relay that has a dummy terminal put on it. That way the cable has somewhere to terminate to, instead of being left loose where perhaps it might otherwise find a means to ground out somewhere (or would simply look untidy, I don't know). It must be cheaper to manufacture the specific relay like that than to make two separate harnesses.

What this means in a 12v. application is that the Black-yellow cable

can be disconnected from the 'S' terminal, carefully wrapped to make sure it can't ground out, and the operation of the glow system will continue just fine. This also means that there might be some options for glow plug relay replacement, which would retain use of the glow controller, a consideration given that most of these older glow plug relays are obsolete out of Toyota, and once our existing ones die, we need some options for replacing them.

Well, I think I can sleep now. Tomorrow I'm going to test this idea out by unhooking the black-yellow from the 'S' terminal and see how things run. I'm confident nothing will change. I wish I had known this when I wired my truck, as it would have saved me a little work to leave that wire off.

light go on. Actually, Tom seems to have slightly beaten me to the punch here, but a

light go on. Actually, Tom seems to have slightly beaten me to the punch here, but a  ...

...