When I looked into air lockers I saw this ARB demo video where the guy looked like he was playing dashboard piano when he went to operate those big switches. I thought, no....Toyota got it right with the single rotary switch. But how would I integrate it with the OBA system and maintain the factory behaviour?

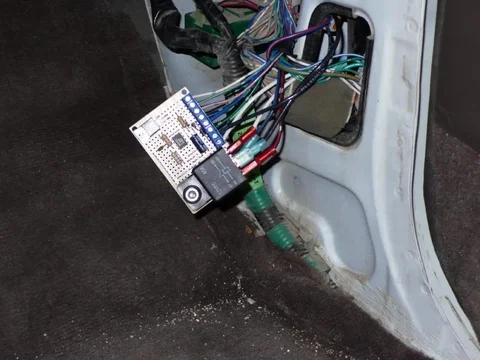

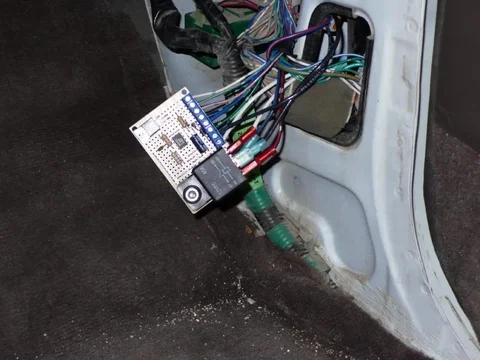

Got the EWD and started tinkering, here's the prototype:

Here's what it does:

1) Integrates the factory wiring, switch and lamps with the OBA system.

2) Diables solenoids until the center is locked (this feature provides compressor isolation.)

3) Flashes the lamps to indicate a prohibited operation.

4) Maintains factory appearance.

What it does NOT do:

1) Provide a maximum speed inhibit (maybe on version 2.0)

2) Act as a drop-in replacement for a factory E-locker system.

3) Save you money.

I will be happy to provide details.

Got the EWD and started tinkering, here's the prototype:

Here's what it does:

1) Integrates the factory wiring, switch and lamps with the OBA system.

2) Diables solenoids until the center is locked (this feature provides compressor isolation.)

3) Flashes the lamps to indicate a prohibited operation.

4) Maintains factory appearance.

What it does NOT do:

1) Provide a maximum speed inhibit (maybe on version 2.0)

2) Act as a drop-in replacement for a factory E-locker system.

3) Save you money.

I will be happy to provide details.

Last edited: