Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi-Lift jack 101, why won't it ratchet down? (1 Viewer)

- Thread starter brider

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Coolerman:

I have the same blue high lift and have changed the cotter pin in the base as the company now says it is prone to come loose. I used a high grade bolt and nut (drilled out some material) and it is solid now.

Just a heads up especially if you hang your high lift from your bumper ect.

I have the same blue high lift and have changed the cotter pin in the base as the company now says it is prone to come loose. I used a high grade bolt and nut (drilled out some material) and it is solid now.

Just a heads up especially if you hang your high lift from your bumper ect.

- Joined

- Feb 27, 2007

- Threads

- 76

- Messages

- 448

- Location

- Tuscaloosa Ala. ROLL TIDE!!!

- Website

- www.myspace.com

x2 wd40 will gunk up after awhile, (dusty trails). water is finei just pour water on mine

the best way to keep the pins in good shape that I've found is the liquid ice that mountain bikers use on their bicycle chain. It doesn't pick up dirt or grime and stays on pretty well. I've also had good luck paiting the pieces with slip-plate

bk

bk

The spring kit with the two little rod pieces costs $25 plus shipping. Ouch. My HL cost $50.

Go with the WD40

Check local farm supply stores. I don't remember what it was but much less than that at the local Big R. The jack was 48.95, I think the tune up kit was maybe $10. I'll look next time I stop in.

FJ40-GARAGE

I`ll be back....

I use dishwasher liquid to lube it, the glyzerin keeps it in good condition and the dirt is easy to wash off after wheeling.

And.......no greased or dirty hands after all.

JT Outfitters has the Fix It Kit for 13.95

And.......no greased or dirty hands after all.

JT Outfitters has the Fix It Kit for 13.95

Last edited:

Hey Guys,

I know this is an ooooooooooold thread, I just wanted to share my experience as I was having the same issue.

Much like OP, no matter what I did, my hi lit jack would not ratchet down. I tried lubing it up, banging it, sort of pushing side to side, throwing the handle down hoping to get it to bump down, take it completely apart...... nothing worked.

So today as I took it apart once again, I noticed that the bottom cross pin was slightly bent. I figure it was bent just enough that would cause the climbing pins not to catch. I threw the pin in the vice and bent it straight. I put the jack under a load and

'voila!' it worked as it should!! Such a relief after a year of it not working properly.

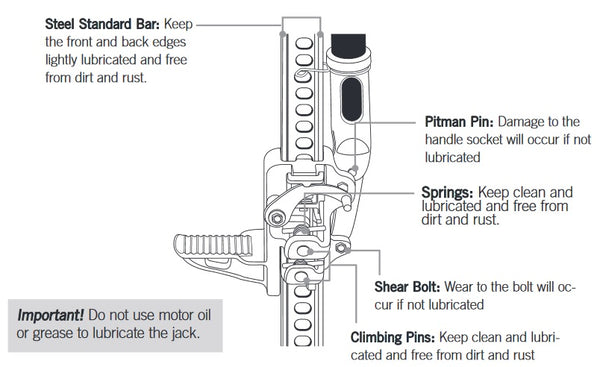

So my advice would be to properly lubricate all lube points. I use Jig-A-Loo. Its a silicone-based lubricant and water-repellent spray. Hands down the best Ive used. Kills wd-40.

And make sure all bolts are straight and not damaged (taking note of the cross pins and sheer bolt)

I know this is an ooooooooooold thread, I just wanted to share my experience as I was having the same issue.

Much like OP, no matter what I did, my hi lit jack would not ratchet down. I tried lubing it up, banging it, sort of pushing side to side, throwing the handle down hoping to get it to bump down, take it completely apart...... nothing worked.

So today as I took it apart once again, I noticed that the bottom cross pin was slightly bent. I figure it was bent just enough that would cause the climbing pins not to catch. I threw the pin in the vice and bent it straight. I put the jack under a load and

'voila!' it worked as it should!! Such a relief after a year of it not working properly.

So my advice would be to properly lubricate all lube points. I use Jig-A-Loo. Its a silicone-based lubricant and water-repellent spray. Hands down the best Ive used. Kills wd-40.

And make sure all bolts are straight and not damaged (taking note of the cross pins and sheer bolt)

I always use a hammer to move the lever. It needs the shock of the hammer to activate in the different directions. Sometimes I can do by hand, but a tap in the direction I want to go makes it work.

I like spray silicon if I am going to lube anything. Doesn't attract dirt.

I like spray silicon if I am going to lube anything. Doesn't attract dirt.

I'm like Manu on this - disassembled inside the truck and put it together when needed. I switched out connecting hardware for the handle and foot base with linch/clevis pins. I had to drill out the holes a bit to fit 1/4" pins, but all works great. Having a removable handle is nice when you need a cheater bar during maintenance work.

One of these for the handle:

and one of these for the foot base:

The ratcheting assembly just stays in the cargo box area. I mounted the beam to the roof rack using wingnuts.

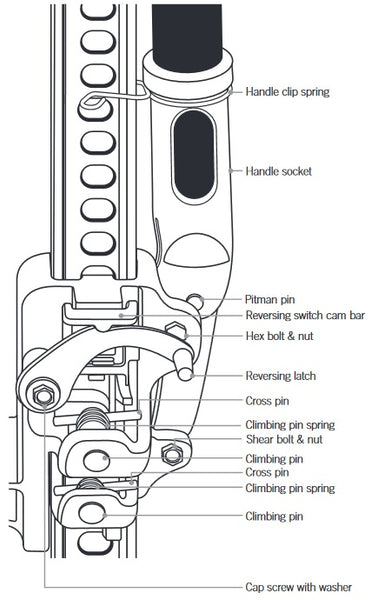

Even with all that protection from the elements (and clean lube on the moving parts), my ratcheting down process when lowering the truck requires that I tap on the reversing switch cam bar to get the load bearing pins to transfer. I do the tapping at the end of the down stroke of the handle. Handle all the way down, tap on the cam bar. Handle all the way up, it usually cycles on its own. Repeat.

One of these for the handle:

and one of these for the foot base:

The ratcheting assembly just stays in the cargo box area. I mounted the beam to the roof rack using wingnuts.

Even with all that protection from the elements (and clean lube on the moving parts), my ratcheting down process when lowering the truck requires that I tap on the reversing switch cam bar to get the load bearing pins to transfer. I do the tapping at the end of the down stroke of the handle. Handle all the way down, tap on the cam bar. Handle all the way up, it usually cycles on its own. Repeat.

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)