So, I'm in the process of converting over from V-belt to a serpentine setup. I chose to use Chevrolet factory brackets instead of paying the premium for aftermarket billet parts. One of the problems I ran into was missing accessory mounting holes in the passenger side head. The only hole my head (441 casting) had was high on the exhaust side of the head. The truck bracket I bought wanted another hole lower on the intake side of the head. Finding information about where the factory placed the holes has been next to impossible. The best I've been able to do is get information from Brodix as to where they machined the holes in their heads, presumably to match the factory locations.

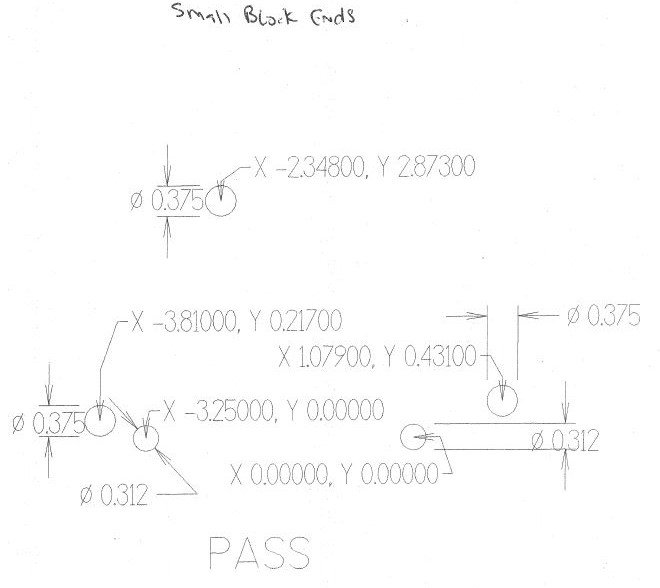

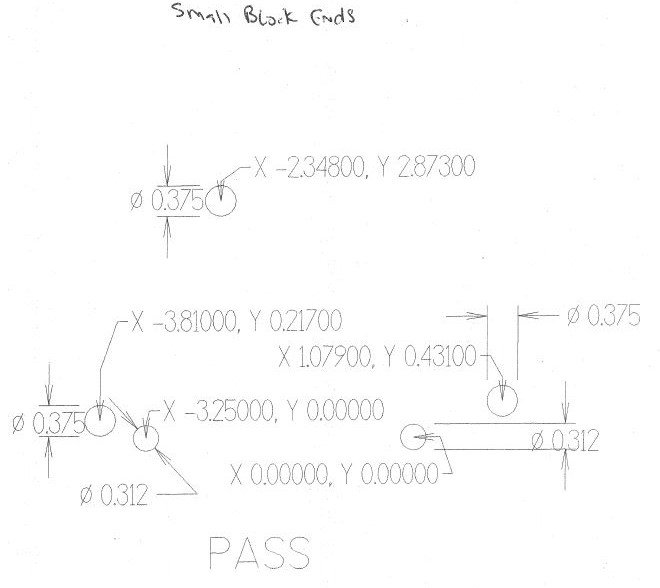

I took the coordinates from their CNC data and used it to enter the hole locations in a CAD program called DeltaCad. I figured I could reference off the one hole my head has to locate the second hole I needed. Here is what I got:

Now I'm going to take this data and plot out where I need to drill and tap the far right lower hole which is on the intake side of head. I'm also going to mount the bracket and use a transfer punch through the bracket to locate the hole. Between these two pieces of information I figure I have the best chance of getting the hole where it needs to be.

I figured this information might be helpful to others attempting the same thing.

I checked the distance between holes on my bracket which confirms that the 4.157" figure is right on per my calipers.

I took the coordinates from their CNC data and used it to enter the hole locations in a CAD program called DeltaCad. I figured I could reference off the one hole my head has to locate the second hole I needed. Here is what I got:

Now I'm going to take this data and plot out where I need to drill and tap the far right lower hole which is on the intake side of head. I'm also going to mount the bracket and use a transfer punch through the bracket to locate the hole. Between these two pieces of information I figure I have the best chance of getting the hole where it needs to be.

I figured this information might be helpful to others attempting the same thing.

I checked the distance between holes on my bracket which confirms that the 4.157" figure is right on per my calipers.

Last edited: