And another thing

Sorry for such long post, but you take it for granted people know things and they learn them the hard way. Remember that if your pieces fit up nicely, you're gonna be welding kinda on top of the joint. That might hold fine, but if you get to grinding and you want all those joints to look good and you grind off 80% of the weld, then a crack is gonna develop there. Might look good for a while, but there's not a lot of metal there. On the thin stuff that can be a challenge.

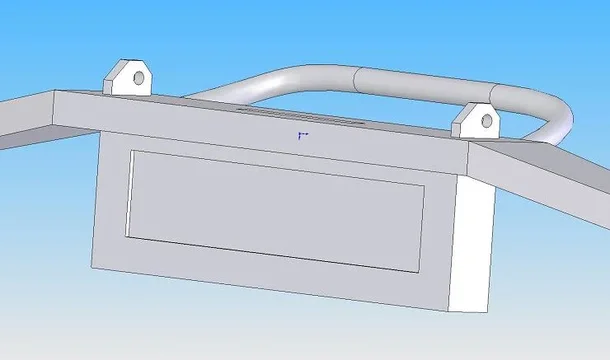

And on those bolts on the frame--do I need to say--make sure they are Grade 8 or something similar.

Nice looking truck too.

Sorry for such long post, but you take it for granted people know things and they learn them the hard way. Remember that if your pieces fit up nicely, you're gonna be welding kinda on top of the joint. That might hold fine, but if you get to grinding and you want all those joints to look good and you grind off 80% of the weld, then a crack is gonna develop there. Might look good for a while, but there's not a lot of metal there. On the thin stuff that can be a challenge.

And on those bolts on the frame--do I need to say--make sure they are Grade 8 or something similar.

Nice looking truck too.