UPDATE:

"The Lorry" is presently in the shop getting a few upgrades...

I located an 80 Series Dual diaphragm brake vacuum booster this is now being fitted.

Front and rear Harrop (Terrain Tamer) E-Lockers

Im removing the Ironman front Coils, front shocks and rear shocks - and replacing them with a set of DCS Remote reservoir adjustable shocks and coils.

Its also having its 5000km Oil and filter change (Im a bit anal about doing oil and filter change every 5000km)

'The Lorry" has 2 sub (aux) tanks, the OEM 90ltr and an additional 60Ltr tank that gravity feeds into the OEM 90Ltr Sub (aux) tank.

During our recent trip to Botswana i noticed there was diesel sweat around the fitting where the OEM sub tank feeds into the secondary 60Ltr Aux tank.

So, both the OEM 90ltr tank and the secondary 60 Ltr aux tank are being removed for pressure testing and repairs.

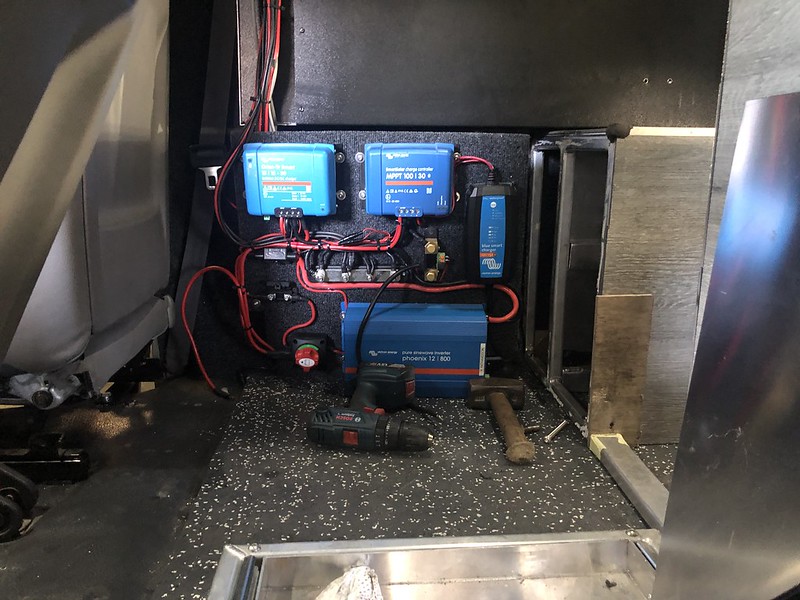

I am also considering moving all my 12V Aux electrickery system, namely the Victron DC/DC charger, Victron MPPT, Victron Shunt, Victron Inverter, Victron 220/12 Batt charger as they are presently inside the side body panel behind the Drivers seat. The reason being, on the Botswana trip, one of my mates has an issue with his Victron DC/DC charger not working, and to gain access to work on it we had to remove the drivers seat. So i thought, , , , , if I ever have an issue and my system needs to be worked on - I will need a contortionist dwarf to gain access. So the plan will be to mount the electrickery system onto a plywood panel spaced and mounted onto the inside of the shower cubicle Gullwing.

The present position.

The plan is now to mount all the electrickery components onto the side of this Gullwing box

Lets hope it works.

The DCS remote reservoir adjustable shocks

please, please

please, please