- Thread starter

- #41

Thanks for the directions… either the dizzy is off or the flywheel timing marks were made on Friday or Monday cause for this thing to stay running good its 15-20 * advanced from the BB according to 2 lights. Maybe I was mistaken and it was never right on the first check and the advance in the gun was not on zero as I thought .

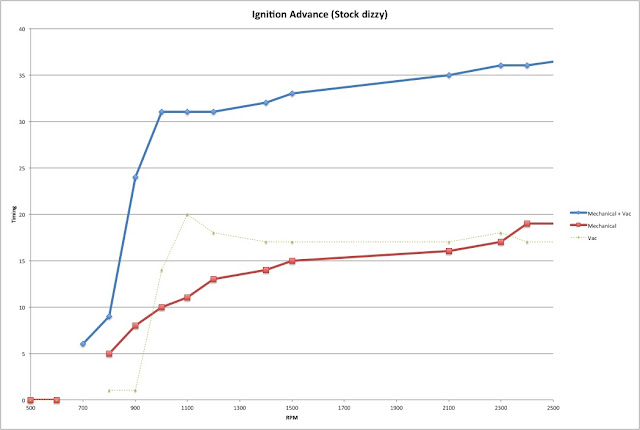

I got it set to where it drives great and idles, although high (around 1k ), but atleast it stays idling. I’ll check tomorrow to see where the button points on TDC / Cyl #1. I also check the button/ mechanical advance.

Thanks for not giving up on me !!!

I got it set to where it drives great and idles, although high (around 1k ), but atleast it stays idling. I’ll check tomorrow to see where the button points on TDC / Cyl #1. I also check the button/ mechanical advance.

Thanks for not giving up on me !!!