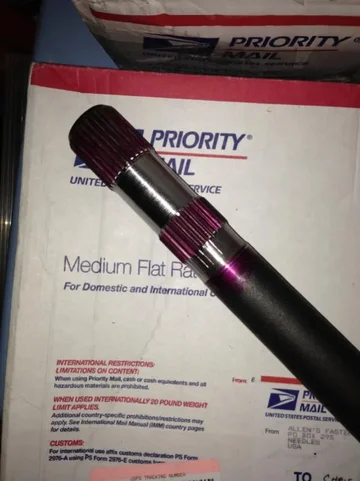

Local kid's 07 rear pinion bearing was determined faulty and considering an 07, he ordered a completed third from ECGS.

My first on the FJC, and kid's short on cash, so be a swap only, against my recommendation we go through the entire axle.

Pretty sure I've a handle on it, but my experience is limited to 80s that I can sit up underneath and not require jack stands. Doesn't take very long to do, period.

I've learned a lot of tricks that would've otherwise gone undiscovered without seeing a few ( well, the few on Mud) of y'alls ( Puulboy's axle lasso being more memorable, having fought once without) so asking for any tips that'll speed the process up, since I've little time to take a breath and will be pushing to get this done in a few hours.

Already soaking in PB. I have red FIPG, but think ECGS supplied the gasket which kid will opt for. Had him get the fill, drain, and gaskets for, already, too.

My first on the FJC, and kid's short on cash, so be a swap only, against my recommendation we go through the entire axle.

Pretty sure I've a handle on it, but my experience is limited to 80s that I can sit up underneath and not require jack stands. Doesn't take very long to do, period.

I've learned a lot of tricks that would've otherwise gone undiscovered without seeing a few ( well, the few on Mud) of y'alls ( Puulboy's axle lasso being more memorable, having fought once without) so asking for any tips that'll speed the process up, since I've little time to take a breath and will be pushing to get this done in a few hours.

Already soaking in PB. I have red FIPG, but think ECGS supplied the gasket which kid will opt for. Had him get the fill, drain, and gaskets for, already, too.