Guys..

A few quick questions-

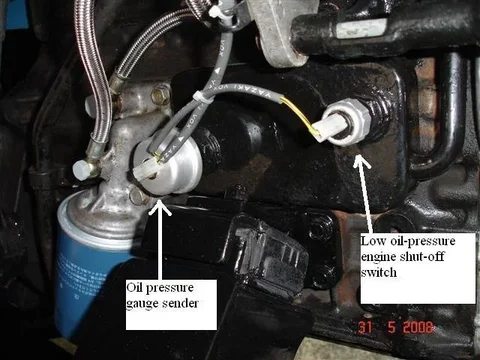

My oil pressure sending unit has 2 terminals.. a round center tap and a spade terminal.. Are they both the same.. How does the cutoff work.. When you have no oil pressure does the switch have high resistance or low ( or does it ground or go open ) ? If I could understand the unit a bit more.. maybe I could design my own circuit that worked with the fuel solenoid on my rotary inj pump.. in the 3b manual it seems to keep talking about an EDIC that I do not have.. it seems to describe a unit that actuates linearly a rod that controls the fuel flow.. I have no such device -

my oil pressure goes immediately to full when I start it.. both with the 2F and 3B motors.. it seems to not matter which sender I use.. they could be both bad.. or something else entirely..

ideas?

Todd

A few quick questions-

My oil pressure sending unit has 2 terminals.. a round center tap and a spade terminal.. Are they both the same.. How does the cutoff work.. When you have no oil pressure does the switch have high resistance or low ( or does it ground or go open ) ? If I could understand the unit a bit more.. maybe I could design my own circuit that worked with the fuel solenoid on my rotary inj pump.. in the 3b manual it seems to keep talking about an EDIC that I do not have.. it seems to describe a unit that actuates linearly a rod that controls the fuel flow.. I have no such device -

my oil pressure goes immediately to full when I start it.. both with the 2F and 3B motors.. it seems to not matter which sender I use.. they could be both bad.. or something else entirely..

ideas?

Todd