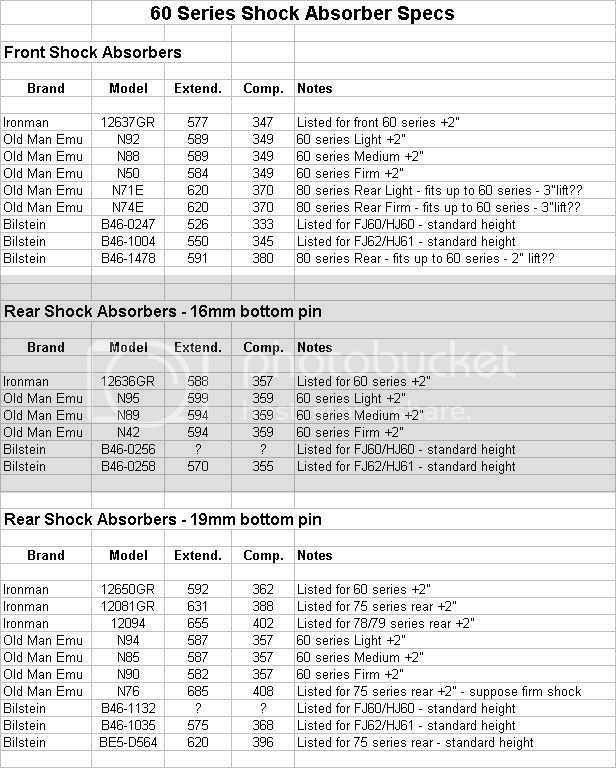

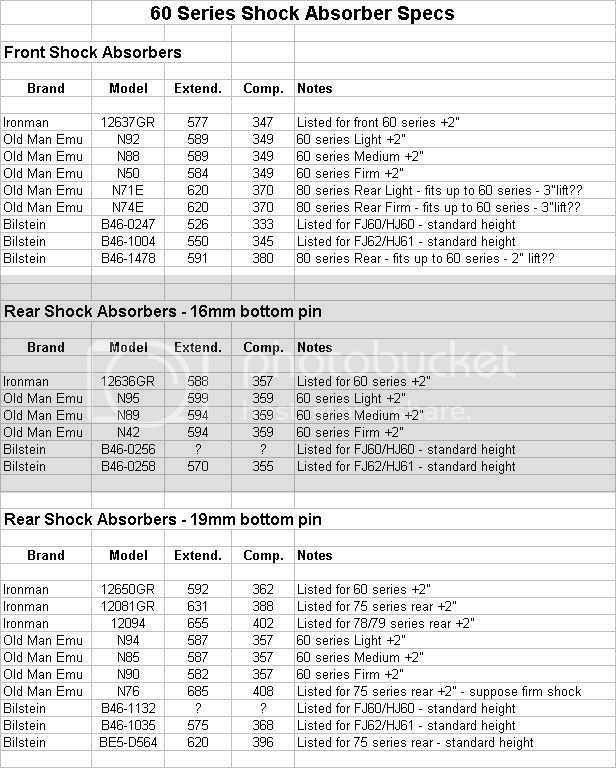

Hi all. I thought I would share some info that I have learned over the last year or so about shock lengths to suit the 60 series Cruisers. I have included info on Ironman shocks, OME and some Bilstein info. Maybe someone can use this info for their benefit and not have to research as much as I have.

BTW, I have included some info on 80 series rear shocks that bolt onto the front of the 60 series. I have never done this, but MAF use rear 80 shocks in their shackle reversal kit and Rancho in Aus list rear 80 series shocks for large lifts in the front of a 60. According to the Bilstein valving reference chart the valving should be similar.

BTW, I have included some info on 80 series rear shocks that bolt onto the front of the 60 series. I have never done this, but MAF use rear 80 shocks in their shackle reversal kit and Rancho in Aus list rear 80 series shocks for large lifts in the front of a 60. According to the Bilstein valving reference chart the valving should be similar.