Hi again Donbugge.

That's the governor housing so I would not expect to find any fuel beneath that cover (based on the fact that there's no fuel anywhere inside my old B-engine's governor).

I must say I am impressed by your engine... It looks to be the ideal transplant choice because, it's got extra cubes (at 4101cc), it's turboed, but most of all, because I love inline pumps so much!

Obviously another 15BFT FSM (that I don't have) comes after RM464E and covers this particular engine (and this FSM will probably be dated May 1996).

But thanks to your details (1998 BU142), I've can now be more certain about getting the correct information off the EPC (and I note that engine was supplied to the General market as well as to the EU).

And I note also (from looking it up) that your primer pump hangs off one of the fuel connections on your fuel filter.

With that fuel line running back to your tank and with the return-line fuel routing I see on your IP, once you've used the primer pump to bleed your filter (and purged air from the bleed nipple there) I believe the IP should automatically purge itself of air (without the need to open another nipple).

But perhaps it would pay to double check that it's full of fuel by opening up something somewhere...

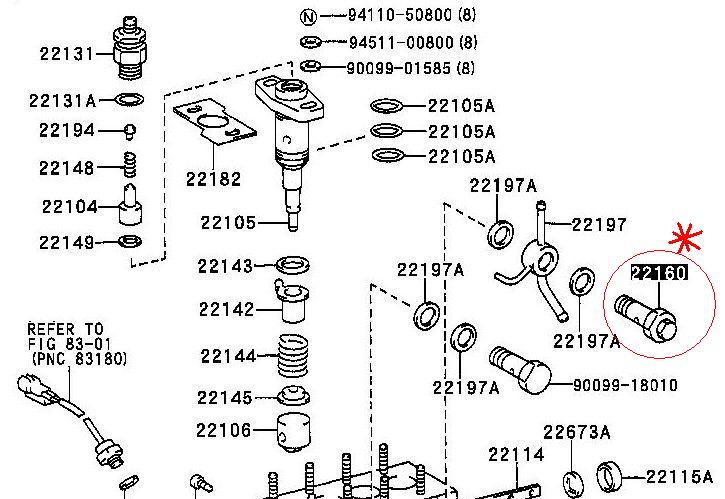

The EPC shows a bleed nipple here on this hollow banjo bolt:

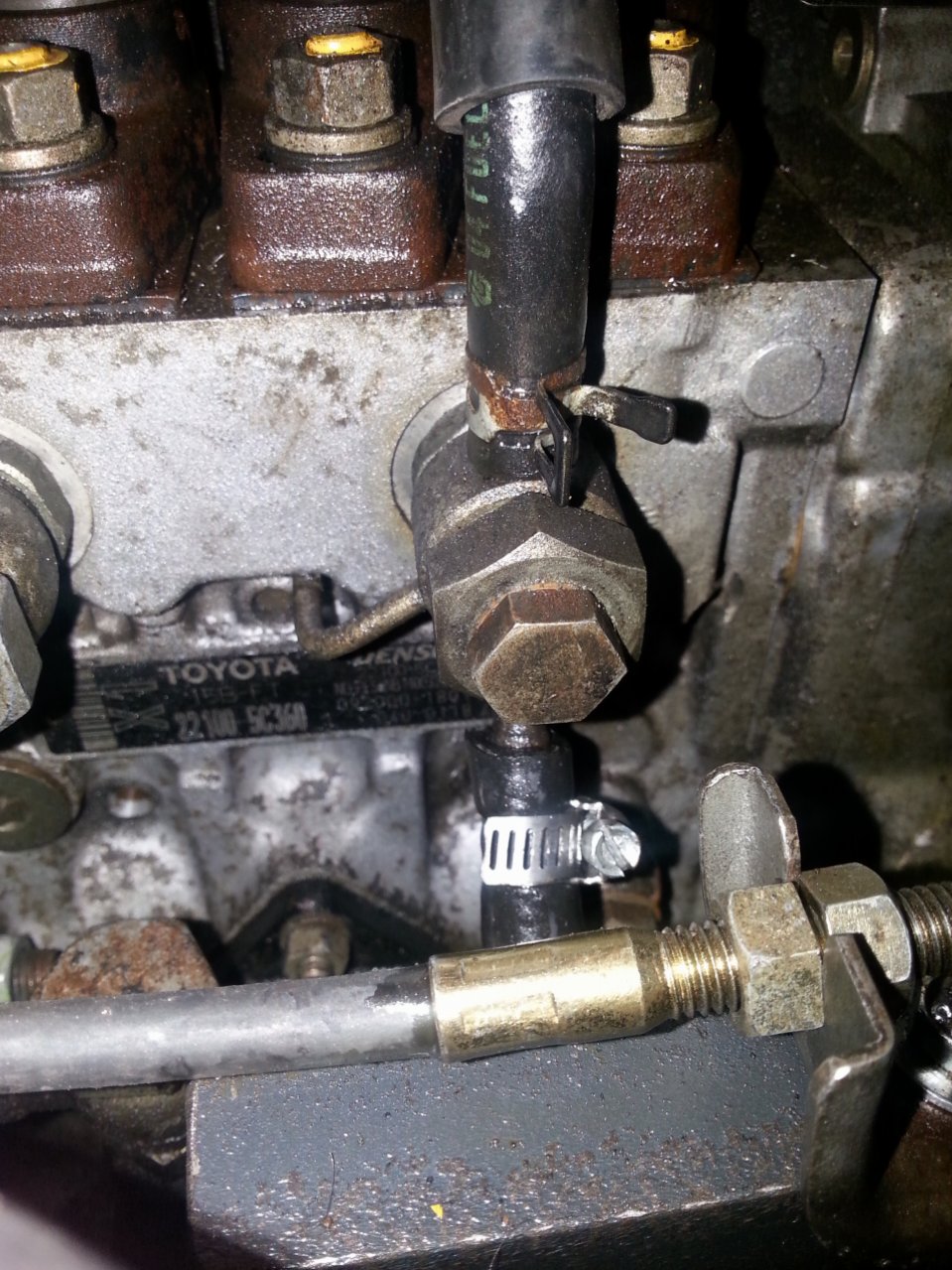

And your photo shows it too:

Have you opened that (while operating your primer) to confirm your IP is full of fuel?

And where does the line heading vertically upwards from this banjo go to?

Right now I'm seeing exactly the same pic that I posted in post #9 (so I accidentally got that one right) as applying to your "inline-pump engine"... And once again I see that top-right actuator labelled as "Fuel Cut" (for a 15BFT/BU142).

And here it is in your photo:

I'm wondering if this may somehow have it's linkage sitting in the fuel-cut position (as another possible reason for why your IP doesn't ejaculate fuel when you crank your engine)?

That's the governor housing so I would not expect to find any fuel beneath that cover (based on the fact that there's no fuel anywhere inside my old B-engine's governor).

I must say I am impressed by your engine... It looks to be the ideal transplant choice because, it's got extra cubes (at 4101cc), it's turboed, but most of all, because I love inline pumps so much!

Obviously another 15BFT FSM (that I don't have) comes after RM464E and covers this particular engine (and this FSM will probably be dated May 1996).

But thanks to your details (1998 BU142), I've can now be more certain about getting the correct information off the EPC (and I note that engine was supplied to the General market as well as to the EU).

And I note also (from looking it up) that your primer pump hangs off one of the fuel connections on your fuel filter.

With that fuel line running back to your tank and with the return-line fuel routing I see on your IP, once you've used the primer pump to bleed your filter (and purged air from the bleed nipple there) I believe the IP should automatically purge itself of air (without the need to open another nipple).

But perhaps it would pay to double check that it's full of fuel by opening up something somewhere...

The EPC shows a bleed nipple here on this hollow banjo bolt:

And your photo shows it too:

Have you opened that (while operating your primer) to confirm your IP is full of fuel?

And where does the line heading vertically upwards from this banjo go to?

Right now I'm seeing exactly the same pic that I posted in post #9 (so I accidentally got that one right) as applying to your "inline-pump engine"... And once again I see that top-right actuator labelled as "Fuel Cut" (for a 15BFT/BU142).

And here it is in your photo:

I'm wondering if this may somehow have it's linkage sitting in the fuel-cut position (as another possible reason for why your IP doesn't ejaculate fuel when you crank your engine)?