Awl_TEQ

Supporting Vendor

I plan on making mine this coming April. Last time I made three sets for a local guy that does NOS restorations. That was like three years ago so I can't even remember what gauge of steel I used. I think it was 16 but could have been 14 - I have all the info at work but I'm off till the 5th and it's all the way across town. I also don't have an actual cost until I check material prices as well.

People reading this thread and thinking of asking for a side or a set should know the following:

1) There is no wheel arch rib - I have no way of stamping it in.

2) These are punched out on a CNC Turret punch - not stamped in a press.

3) The hip, main rib and perimeter flanges are formed on a 10' Amada press brake.

4) The "bumps" that straddle each hook are done one at a time in a manual punch machine.

5) These sides were made to fit a 1978 FJ45 by measuring a removed rusty one - I have no idea if they will fit the late 60's trucks, I've never seen one in person.

6) I have no price until Jan 6th - I have to check current material costs.

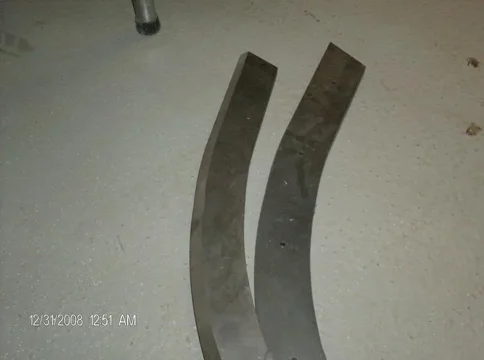

7) The wheel arch rib is a laser cut 1/2" thick drilled/tapped and bolted on affair - see pic three.

8) I can make custom lengths and wheel positions

9) I can also make the end, top and bottom channels for the tailgate as well as a blank tailgate panel - see pic two. (four hinge model)

10) I have made inner walls to make the box double walled - no more dents from cargo - see pic one.

11) I am in Canada and have no idea how to ship these or what customs will require so shipping will be up to the buyer - I would of course package them.

12) You will have to hammer, weld, grind, buff curse and swear to make them perfect after paint - these are NOT NOS PARTS I make them myself.

People reading this thread and thinking of asking for a side or a set should know the following:

1) There is no wheel arch rib - I have no way of stamping it in.

2) These are punched out on a CNC Turret punch - not stamped in a press.

3) The hip, main rib and perimeter flanges are formed on a 10' Amada press brake.

4) The "bumps" that straddle each hook are done one at a time in a manual punch machine.

5) These sides were made to fit a 1978 FJ45 by measuring a removed rusty one - I have no idea if they will fit the late 60's trucks, I've never seen one in person.

6) I have no price until Jan 6th - I have to check current material costs.

7) The wheel arch rib is a laser cut 1/2" thick drilled/tapped and bolted on affair - see pic three.

8) I can make custom lengths and wheel positions

9) I can also make the end, top and bottom channels for the tailgate as well as a blank tailgate panel - see pic two. (four hinge model)

10) I have made inner walls to make the box double walled - no more dents from cargo - see pic one.

11) I am in Canada and have no idea how to ship these or what customs will require so shipping will be up to the buyer - I would of course package them.

12) You will have to hammer, weld, grind, buff curse and swear to make them perfect after paint - these are NOT NOS PARTS I make them myself.

:whoops:

:whoops: