Well, I thought for a moment my horns were broken, or at least somewhere along the lines, the wire was shorted or something. What made me come to this conclusion?

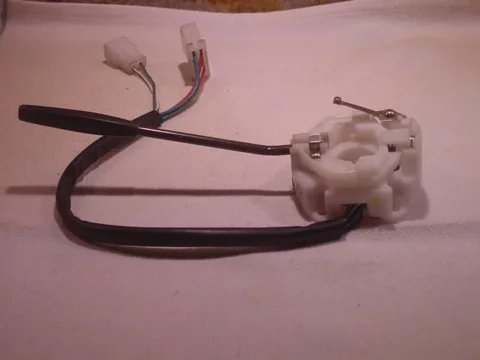

Well, they didn't sounds for one. And using a continuity beeper on my Multimeter, it showed a closed circuit when I touched the two ends on each socket. All this without engine running or anyone touching the horn button. This, plus when I joined one socket with the negative batt post or grounded it anywhere, it showed 24.9v. The other socket showed 12v when joined with the +ve post. This was the same on both sides.

Then on a whim I started the cruiser up and decided to turn the steering wheel around whilst pressing on the horn. Wait...was that a faint beep? Did it again, same thing. So it looks like somehow the horn is working!

So ok, how does this work? I thought there should be no closed circuit until the button is depressed right? How does this work?

The other question of course, is, how do I get the darned steering off to fix the bad contact that must be happening in the steering? I can't move the bloody screws under the 3 posts of the wheel!

Well, they didn't sounds for one. And using a continuity beeper on my Multimeter, it showed a closed circuit when I touched the two ends on each socket. All this without engine running or anyone touching the horn button. This, plus when I joined one socket with the negative batt post or grounded it anywhere, it showed 24.9v. The other socket showed 12v when joined with the +ve post. This was the same on both sides.

Then on a whim I started the cruiser up and decided to turn the steering wheel around whilst pressing on the horn. Wait...was that a faint beep? Did it again, same thing. So it looks like somehow the horn is working!

So ok, how does this work? I thought there should be no closed circuit until the button is depressed right? How does this work?

The other question of course, is, how do I get the darned steering off to fix the bad contact that must be happening in the steering? I can't move the bloody screws under the 3 posts of the wheel!