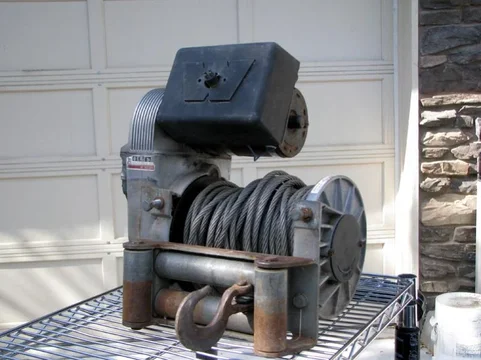

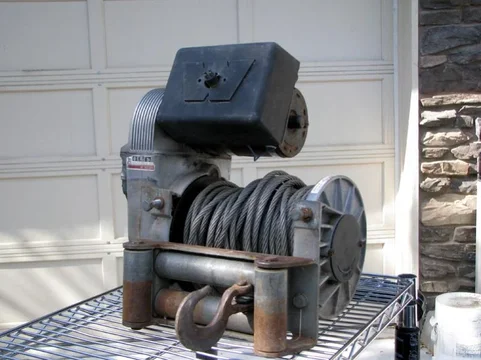

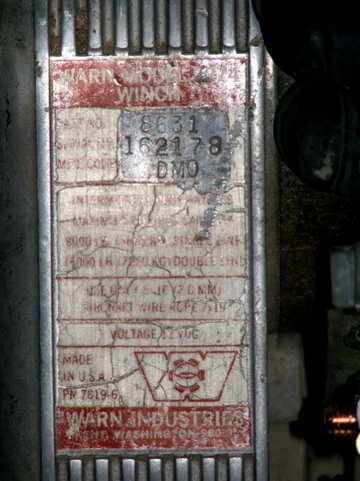

I found this old work horse for $350 on the local Craig's list.

The ad said "$350 FIRM" but the guy went to $250 without me doing anything other than stand there and watch him demonstrate that it worked.

In any case ....... I got it home and took a few pictures to post here.

I'll sell the mounting plate and the weird hitch mount ..... I'll be using a ARB bumper to mount it to my FJ40.

I was really looking hard at the Engo winches after reading the really positive reviews that the 4X4 rag reported on it (listed in one of the threads here) and another review I found on the 'net.

I mean at under $400 for the E12000 'delivered', and with the results of the how well they performed after the torture they put them through in the tests, it was difficult to pass on.

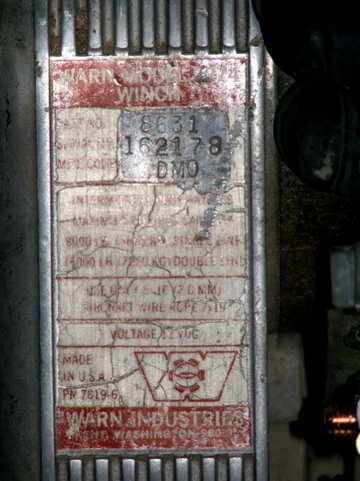

But I figured that I know the 8274 will have parts available for it for longer than I'm probably going to be around. And since my FJ is a '74 with a Saginaw power steering conversion (meaning that the 8274 is abut the only winch that I know that will fit between the frame horns) and because the rest of the FJ40 community pretty much 'expects' to see their brother FJ owners sporting 8274s, I went ahead and wrote the guy a check for it, and he loaded it in my vehicle for me.

I'll pull it apart this spring and go through it, update and rebuild what makes sense to, and then mount it behind the ARB Bull Bar (the new style one) and have a good winch for a fraction of the price of a new one (which BTW: for those looking to buy a new M8274-50 works out to right about $1220 on sale 'delivered' from Warn Factory Outlet @ $1469 and with the $250 Warn rebate ....... good through May 31, see: Warn Industries - Factory Authorized Rebate )

Here's some pictures ....

The ad said "$350 FIRM" but the guy went to $250 without me doing anything other than stand there and watch him demonstrate that it worked.

In any case ....... I got it home and took a few pictures to post here.

I'll sell the mounting plate and the weird hitch mount ..... I'll be using a ARB bumper to mount it to my FJ40.

I was really looking hard at the Engo winches after reading the really positive reviews that the 4X4 rag reported on it (listed in one of the threads here) and another review I found on the 'net.

I mean at under $400 for the E12000 'delivered', and with the results of the how well they performed after the torture they put them through in the tests, it was difficult to pass on.

But I figured that I know the 8274 will have parts available for it for longer than I'm probably going to be around. And since my FJ is a '74 with a Saginaw power steering conversion (meaning that the 8274 is abut the only winch that I know that will fit between the frame horns) and because the rest of the FJ40 community pretty much 'expects' to see their brother FJ owners sporting 8274s, I went ahead and wrote the guy a check for it, and he loaded it in my vehicle for me.

I'll pull it apart this spring and go through it, update and rebuild what makes sense to, and then mount it behind the ARB Bull Bar (the new style one) and have a good winch for a fraction of the price of a new one (which BTW: for those looking to buy a new M8274-50 works out to right about $1220 on sale 'delivered' from Warn Factory Outlet @ $1469 and with the $250 Warn rebate ....... good through May 31, see: Warn Industries - Factory Authorized Rebate )

Here's some pictures ....

Last edited: