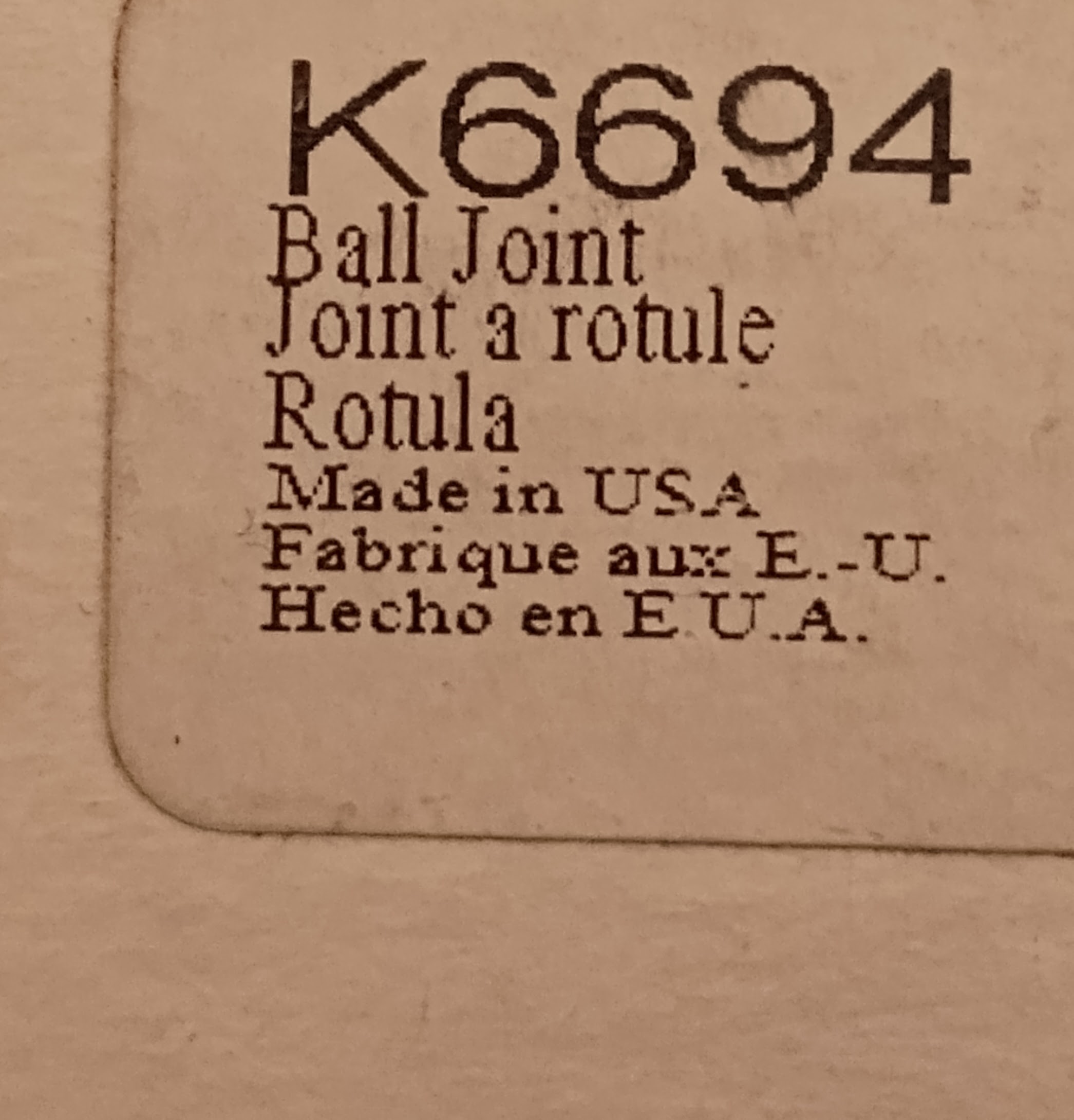

I thought I'd post my slightly unorthodox and budget friendly UCA recommendation here. I recently swapped to aftermarket UCA's on my GX470. My GX is lifted about 2.5 inches in front and my objective was to find a reasonably priced way to restore geometry and to have a high quality, OEM comparable ball joint that was readily available at parts stores. I ended up ordering a couple different sets of UCA's from Amazon. There's quite a range of options in the $100-$200 range that all look very similar. I ordered 2 that were from the highest volume sellers and seemed to have the best reviews. When they arrived I looked over both of them and found no discernible difference between the 2 brands. Both looked and felt quite robust. Even the various SKU and product numbers on the outside of the cartons matched. From examining online pics, both looked like a duplicate of the Freedom Offroad UCA's, the ball joints likely being the only difference. The units i ended up keeping are sold by "Philtop" https://www.amazon.com/gp/product/B0BQW1ZYS2?ie=UTF8&th=1 I pressed out the included ball joints and replaced them with moog 6694 ball joints, which I'd read in a few places are a direct replacement for the ball joints that come in the Freedom Off road UCA's. The Philtop ball joints i removed had a nylon insert in the socket and ended up being about 2.5 hundredths smaller OD than the Moogs I wanted to install. The Philtop ball joints were about 1 hundredth larger OD than the mounting hole of the Philtop UCA they came out of. I imagine this is standard disparity for a press fit, so I planned on maintaining that same disparity when enlarging the mounting hole to accommodate the Moogs. I enlarged the mounting hole on the philtop UCA using a 2" diameter by 1" wide 40 grit abrasive flap wheel. The 2" wheel compressed enough to fit the 1.78" ball joint mounting hole with enough pressure to press firmly against the inside of the bore and remove material effectively. It took around 5 minutes and 2 wheels per arm to bore it out to the needed 1.805" to firmly hold the 1.815" Moog 6694 ball joint. The top flange of the 6694 also had to have a few hundredths shaved off it's diameter to fit into the larger upper bore of the UCA mounting hole where the snap ring grooves reside. This was easily done by turning the ball joint against the grinding wheel of a high speed bench grinder. I thoroughly wrapped the boot and stud of the ball joint with masking tape to keep any metal filings out. The Moogs pressed in perfectly after this, and the arms bolted on to the GX with no issues. It was easier than it probably sounds, once i found the right means of boring out the ball joint mounting hole. I tried a few other things beforehand that weren't removing enough metal. I also used a small sanding drum to remove a bit of material from the top of the ball joint stud mounting hole on top of the steering knuckle. The taper of the 6694 stud is practically identical to the factory ball joint, but i could discern a slight bit of movement near where the ball joint stud exited the bottom of the tapered knuckle mounting hole. Anyhow, hope this makes sense. Sorry for the detail, but I didn't think to take pictures while I was doing the work. I had a couple different front end noises that went away after installing these arms and the shop was able to get the camber fully back into spec. Time will tell how the UCA's hold up. But the Philtop arms look for all the world like the Freedom Off road arms. I'll be checking the arms periodically and try to report back.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enhanced budget UCA option

- Thread starter Couve Cruiser

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?So you took a cheap Chinese UCA, spent a bunch of time modifying it to swap a cheap Chinese balljoint for a different cheap Chinese balljoint all just to end up with a lifted GX that has factory spec. caster? I'm failing to see what is enhanced here.

Last edited:

- Thread starter

- #4

Thanks for the feedback. I suppose a cursory reading of the original post could lead one to some confusion. I'll try to clarify a couple points for anyone looking to use a similar approach. The Moog 6694 is actually made in the USA and is used on a range of 3/4 and 1 ton GM applications. Also, the original post states that I was able to get the camber back in spec. This is due to the arms design positioning the ball joint further outboard and in a more vertical position, compared with the downward pointing (after a lift) stock UCA. The new arms actually allow the caster to be set well beyond the factory spec, due to the ball joint also being positioned a bit further rearward. My caster was at 4.5 degrees after the alignment. This was actually as low as they could get it. The car does steer and handle better at this setting. The arms design also prevents it from contacting the coil spring at full droop, which was happening with the factory arms after the lift. As for the arms construction, time will tell. I'll check he arms regularly, especially after rough road travel. I figure it's good for someone to explore budget UCA options at this point, given the stratospheric prices in the UCA aftermarket. I can't think of another part that seems so expensive for the relative simplicity of the part.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)