Taco2Cruiser

Crazy American Off Road

We all use our 200s differently, from daily driving with families, to towing, weekend camping, to full long term expedition travel.

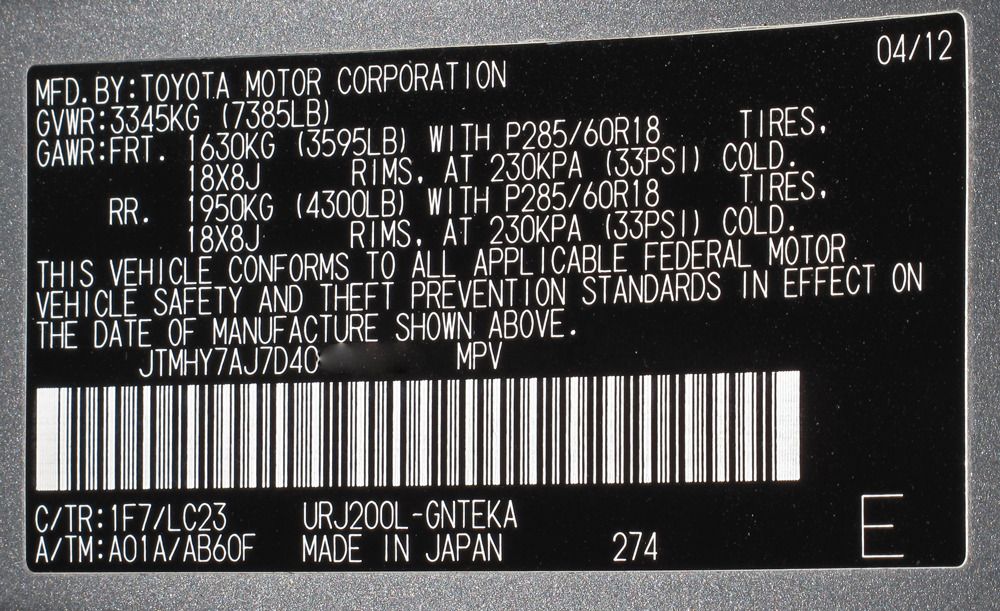

Safely carrying extra weight seems to be an ongoing concern, as it should be. Lives are at stake. I for one use mine for long term remote travel and harder rock crawling trails, that leaves me rather heavy. So I began researching how I can safely increase my payload and GVWR.

In Australia, there are companies that offer legal GVM (gross vehicle mass or Australian DOT for our GVWR) increase kits. These are tested, under government set conditions. Being an American, and proud of it! I still would trust the Australia DOT, if you don't, then this may not be a solution for you.

Lovells Springs is one of those companies, their kit includes just a heavier rate spring that will also lift the truck slightly, longer shocks to accommodate the tall springs, and legal decals stating the new legal GVM. That's it, basically just springs. I was never able to get the actually springs rate used, but Lovell did state they have between 10-50% spring rate increase. This moves the stock GVWR (GVM) to 8,377 lbs (3800kg), regardless of engine or equipment. The split is Front 3968 lbs (1,800kg) and Rear 4409 lbs (2,000 kg)

In the US LC200, stock spring rates are

Front: 500 lbs/in

Rear: 170 lbs/in

Under the most extreme case secanio, a 50% spring rate increase needs to be

Front: 750 lbs/in

Rear: 255 lbs/in

If using Old Man Emu springs, front springs 2701 and 2703 have a rate of 720 lbs/in. Not quite to the 750 mark, yet most weight is placed to the center and rear of the vehicle, while it wouldn't bother me, you need to determine if you are comfortable with that. If using a BP-51, that spring rate is 750 lbs/in, so that meets the mark, and more so as you can further increase preload.

For the rear spring, 2721 and 2722 have a spring rate of 270 and 275 respectively, and meets the mark. Obviously, 2723, 2724 and 2725 are even heavier at 340, 400, and 440 lbs/in respectively.

With variables still unknown, like what spring rate Lovells is actually using outside of knowing their springs are not heavier than 50% more of the stock spring. I feel safe with my BP-51s, and 2724 rear springs (and E rated tires, which the Lovells kit never mentions being required) carrying up to 8,375 lbs.

Also, please check your weight on a certified Cat Scale completely loaded with all people, equipment and full fuel tanks. It's the only way to actually know your weight.

Safely carrying extra weight seems to be an ongoing concern, as it should be. Lives are at stake. I for one use mine for long term remote travel and harder rock crawling trails, that leaves me rather heavy. So I began researching how I can safely increase my payload and GVWR.

In Australia, there are companies that offer legal GVM (gross vehicle mass or Australian DOT for our GVWR) increase kits. These are tested, under government set conditions. Being an American, and proud of it! I still would trust the Australia DOT, if you don't, then this may not be a solution for you.

Lovells Springs is one of those companies, their kit includes just a heavier rate spring that will also lift the truck slightly, longer shocks to accommodate the tall springs, and legal decals stating the new legal GVM. That's it, basically just springs. I was never able to get the actually springs rate used, but Lovell did state they have between 10-50% spring rate increase. This moves the stock GVWR (GVM) to 8,377 lbs (3800kg), regardless of engine or equipment. The split is Front 3968 lbs (1,800kg) and Rear 4409 lbs (2,000 kg)

In the US LC200, stock spring rates are

Front: 500 lbs/in

Rear: 170 lbs/in

Under the most extreme case secanio, a 50% spring rate increase needs to be

Front: 750 lbs/in

Rear: 255 lbs/in

If using Old Man Emu springs, front springs 2701 and 2703 have a rate of 720 lbs/in. Not quite to the 750 mark, yet most weight is placed to the center and rear of the vehicle, while it wouldn't bother me, you need to determine if you are comfortable with that. If using a BP-51, that spring rate is 750 lbs/in, so that meets the mark, and more so as you can further increase preload.

For the rear spring, 2721 and 2722 have a spring rate of 270 and 275 respectively, and meets the mark. Obviously, 2723, 2724 and 2725 are even heavier at 340, 400, and 440 lbs/in respectively.

With variables still unknown, like what spring rate Lovells is actually using outside of knowing their springs are not heavier than 50% more of the stock spring. I feel safe with my BP-51s, and 2724 rear springs (and E rated tires, which the Lovells kit never mentions being required) carrying up to 8,375 lbs.

Also, please check your weight on a certified Cat Scale completely loaded with all people, equipment and full fuel tanks. It's the only way to actually know your weight.

Last edited: